Method for preventing fixed bed biomass gasifier from bridging

A gasifier and biomass technology, which is applied in the mechanical details of gasification devices, the manufacture of combustible gas, and the petroleum industry, etc., can solve the problems of increased cost and difficulty in realization, and can increase the gasification load, eliminate the generation of bridges, The method is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be further described below in combination with specific embodiments.

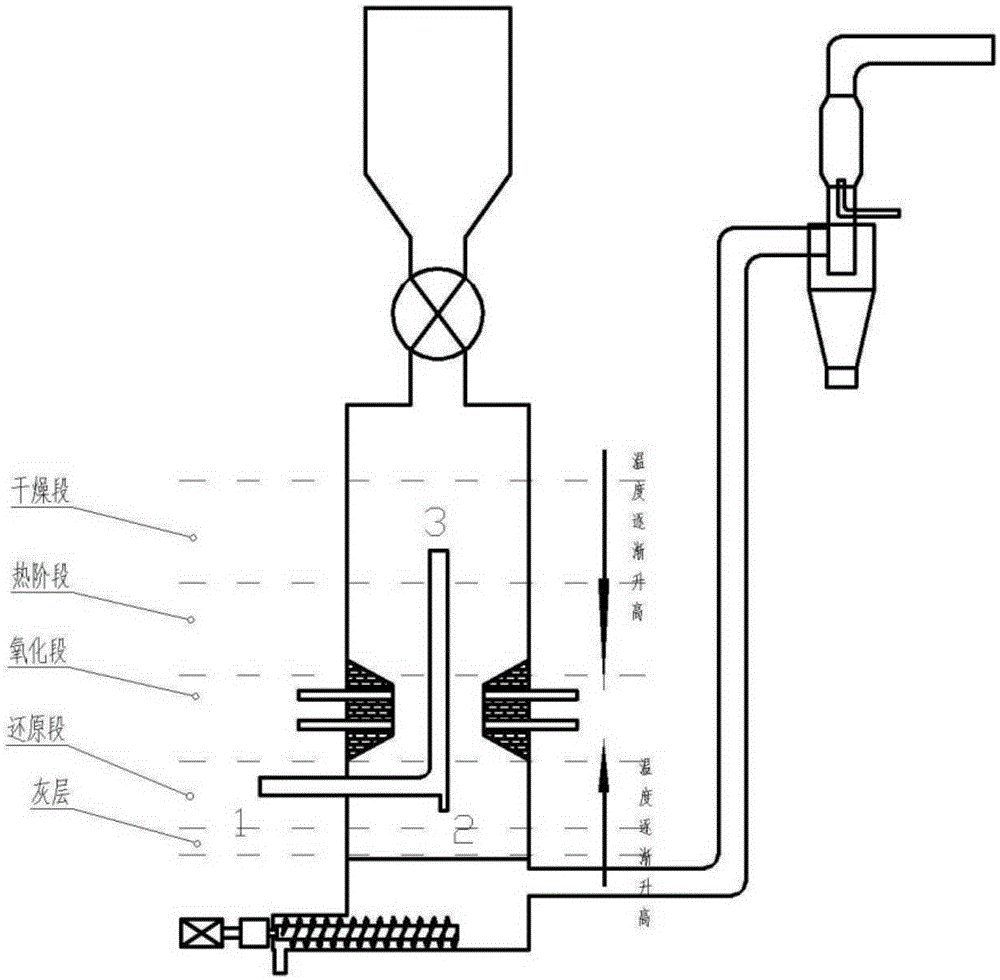

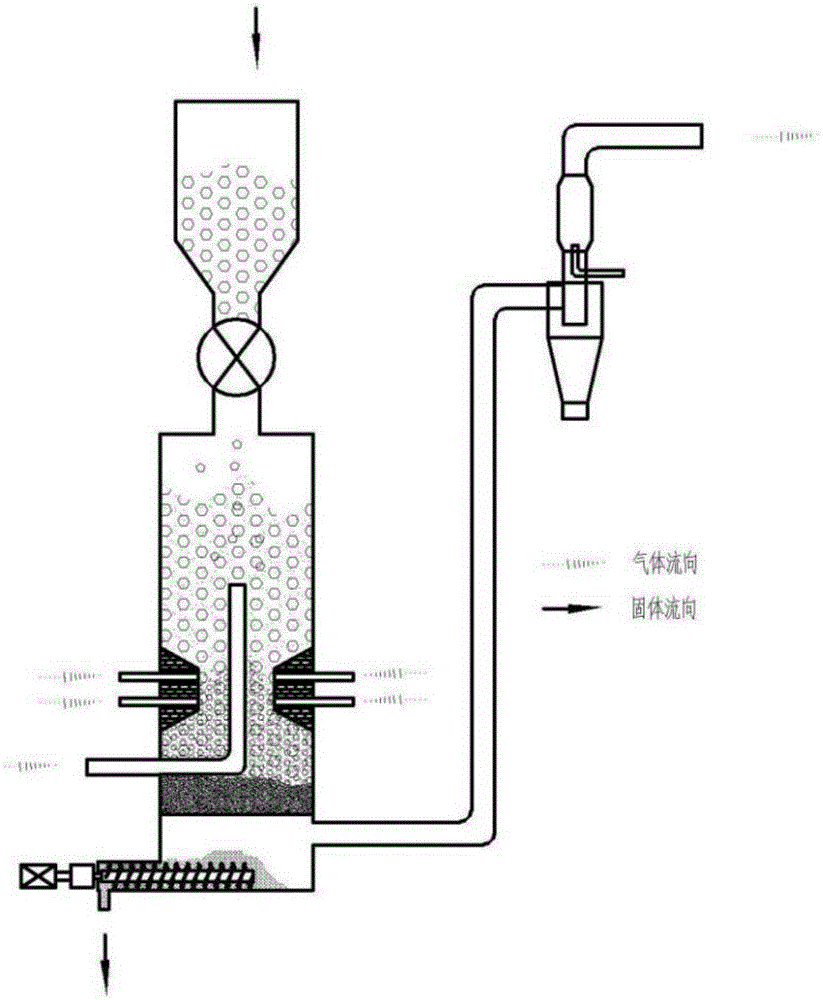

[0015] The method for preventing the bridging of the fixed-bed biomass gasifier of the present invention is to transform the existing biomass gasifier (referred to as the gasifier), and add an air inlet pipe, and the air inlet of the air inlet pipe is arranged at the lower part of the gasifier Near the junction of the ash layer or the ash layer and the high-temperature carbon layer, part of the inlet pipe will pass through the high-temperature section of the gasifier, and the gas outlet is set in the drying section of the gasifier. During operation, the oxidant is introduced from the air inlet, and the oxidant is usually the same as the oxidant currently used for gasification of the gasifier, so as to reduce the operating cost and avoid affecting the gasification conditions. The oxidant flows out from the gas outlet after being heated at a high temperature in the gasifier. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap