Intelligent single line production system for material plasticizing

A production system and single-line technology, applied in the field of intelligent control of material plasticization single-line production system, can solve problems such as insufficient heating temperature of quality and finished products, influence of heating temperature, waste of manpower and cost, etc., to achieve water saving, good quality, and improved The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

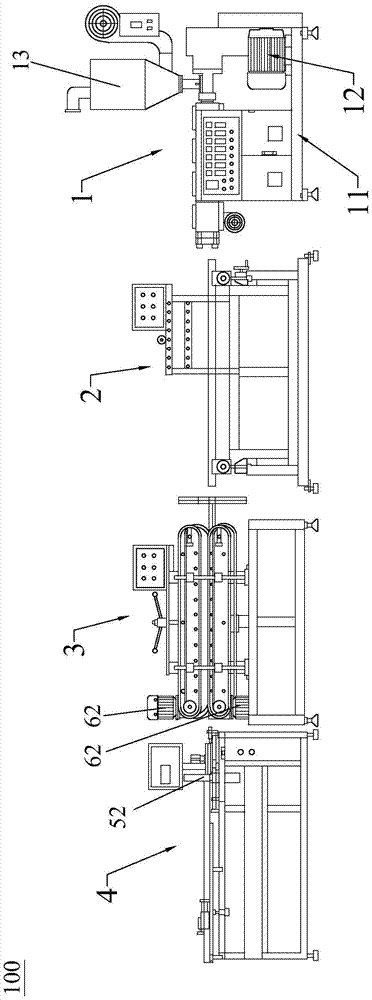

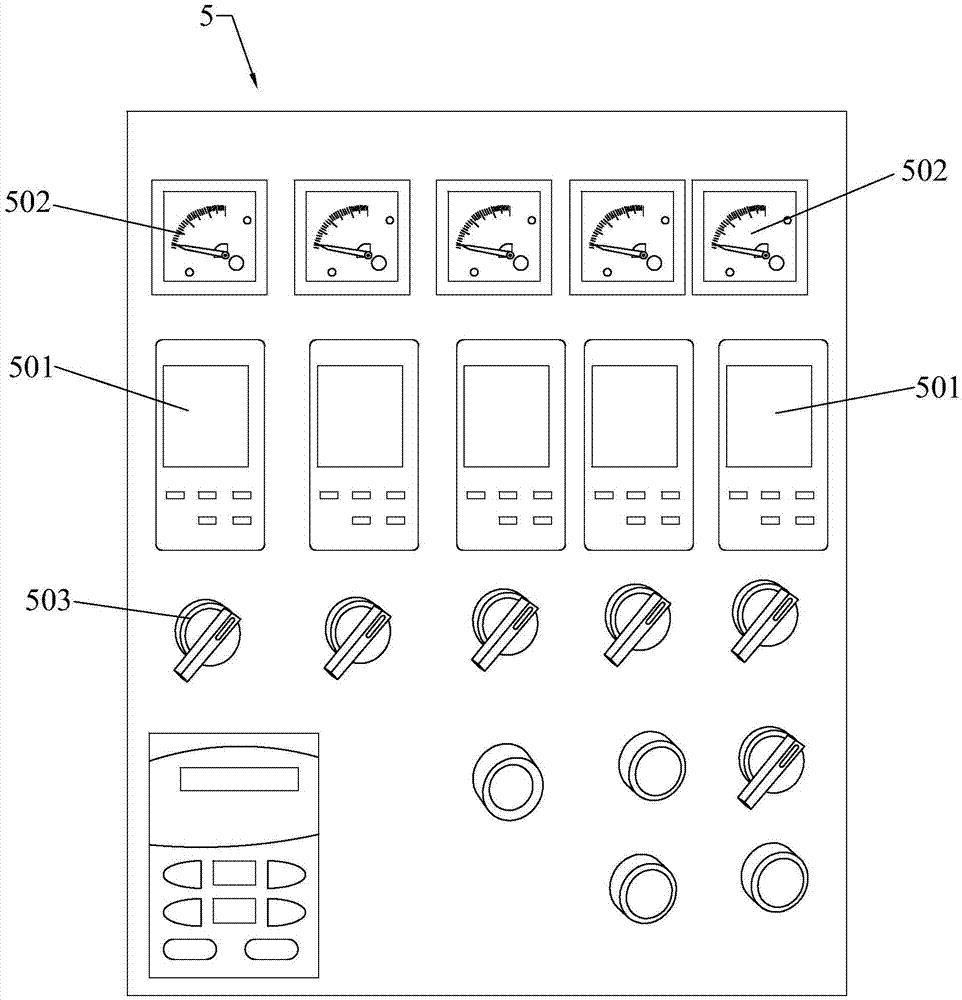

[0022] reference figure 1 , image 3 with Figure 4 , The present invention discloses an intelligent material plasticization single-line production system 100, which is used to extrude plastic particles into hollow-structured plastic products, including an extrusion molding machine 1, a cooling mechanism 2, a discharging traction mechanism 3, a cutting mechanism 4. Detection module, controller 6 and operation display panel 5.

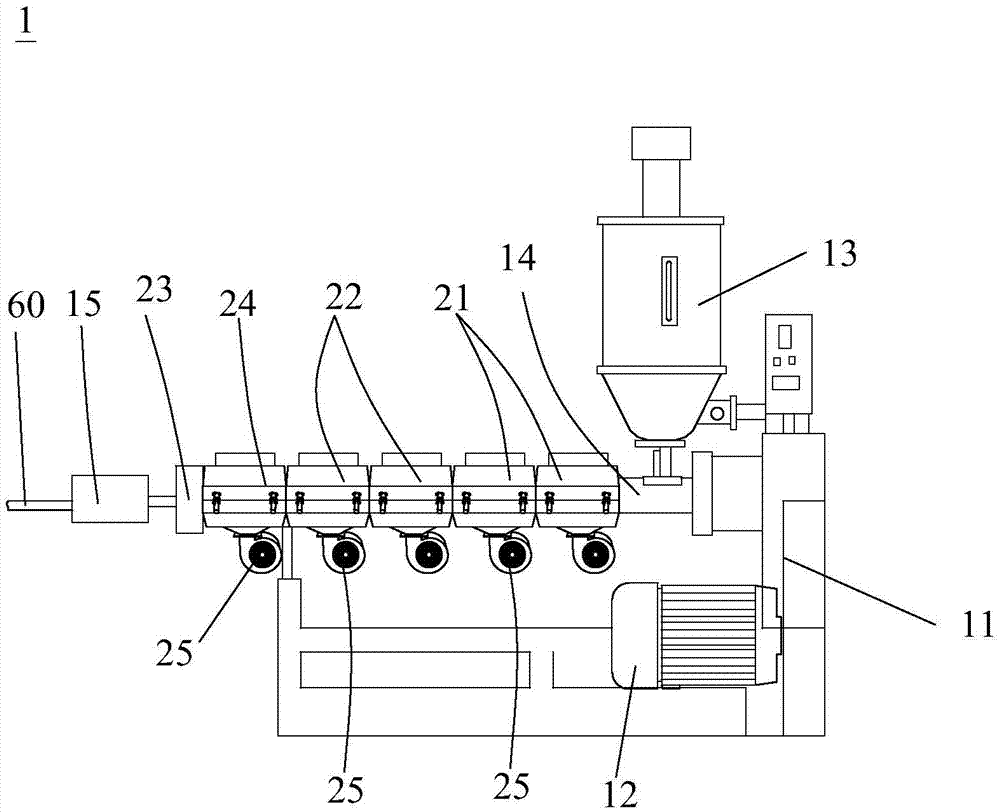

[0023] reference figure 2 The extrusion molding machine 1 includes a base 11, a motor 12, an extrusion screw (not shown), a hopper 13, a barrel 14, a die 15 and a heating element 20, and the motor 12 is installed in the machine On the seat 11, the output shaft of the motor 12 is connected with the extrusion screw, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap