Biomass fuel pelletizing device

A technology of biomass fuel and control device, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high labor intensity and low pelletizing efficiency of operators, so as to improve pelletizing efficiency, reduce labor intensity and reduce participation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

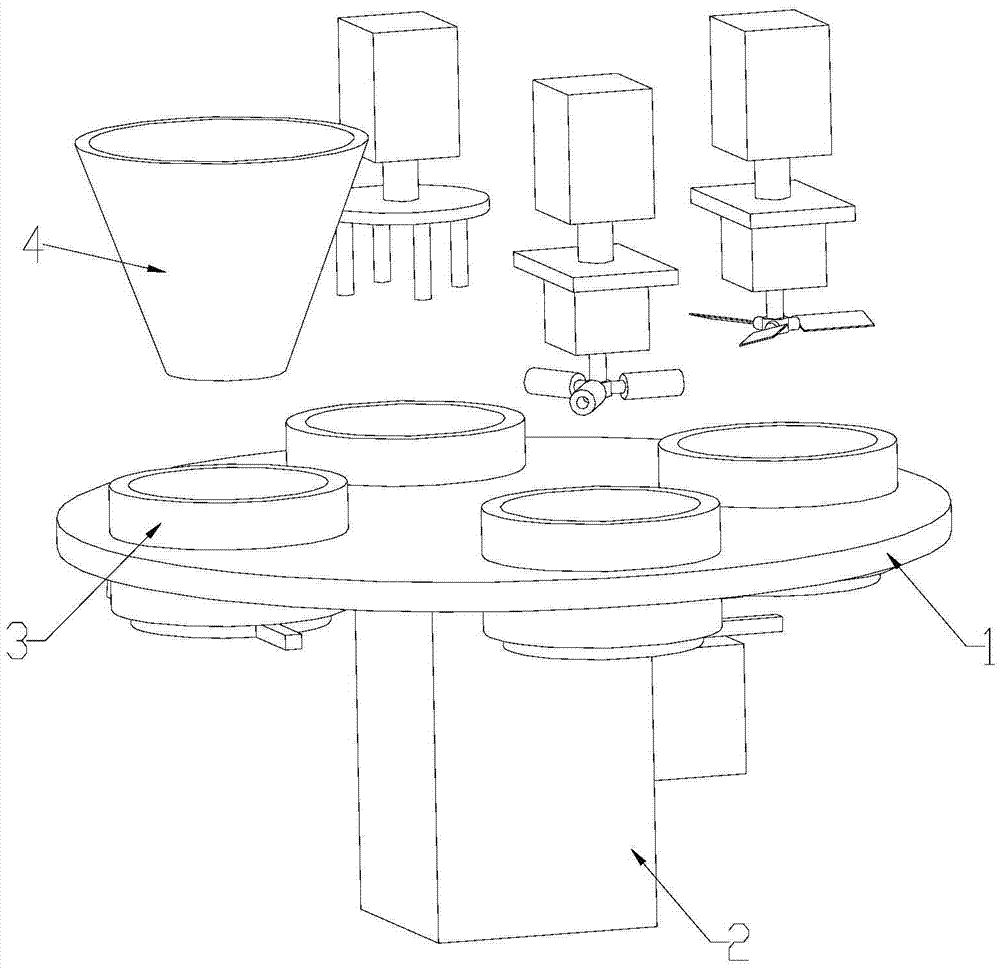

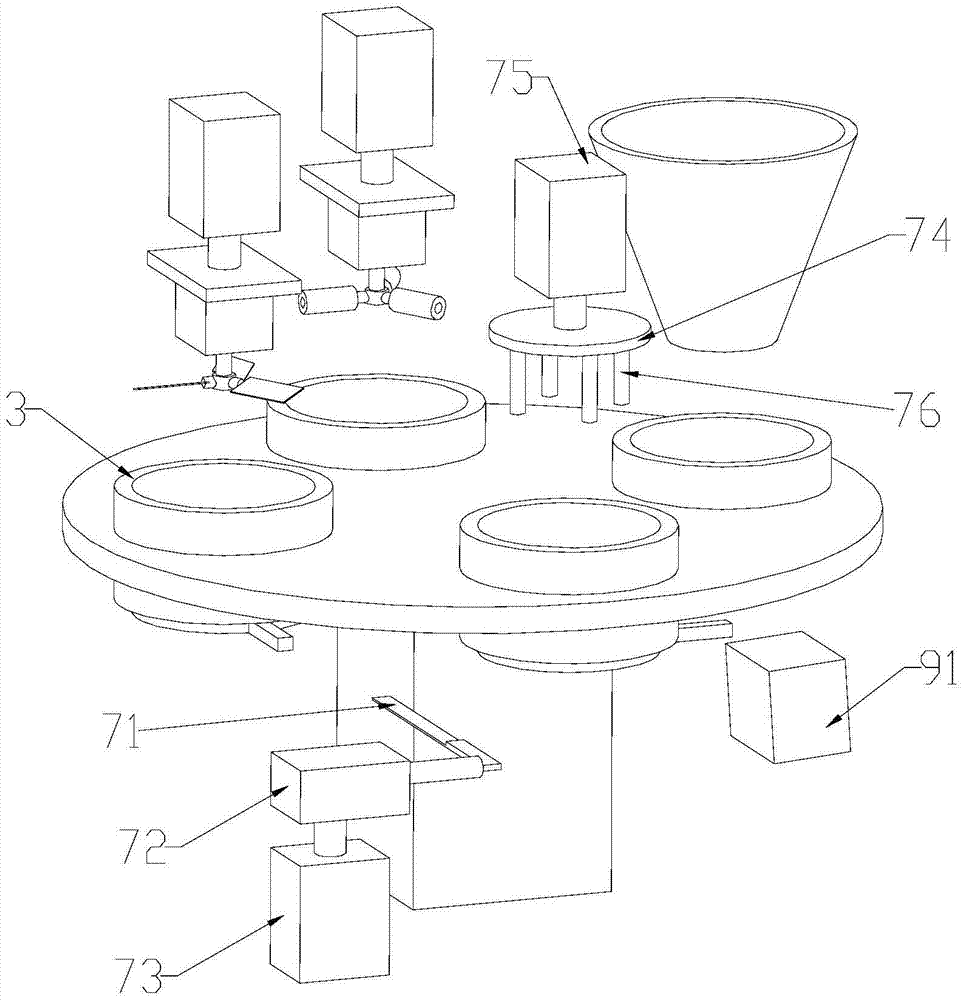

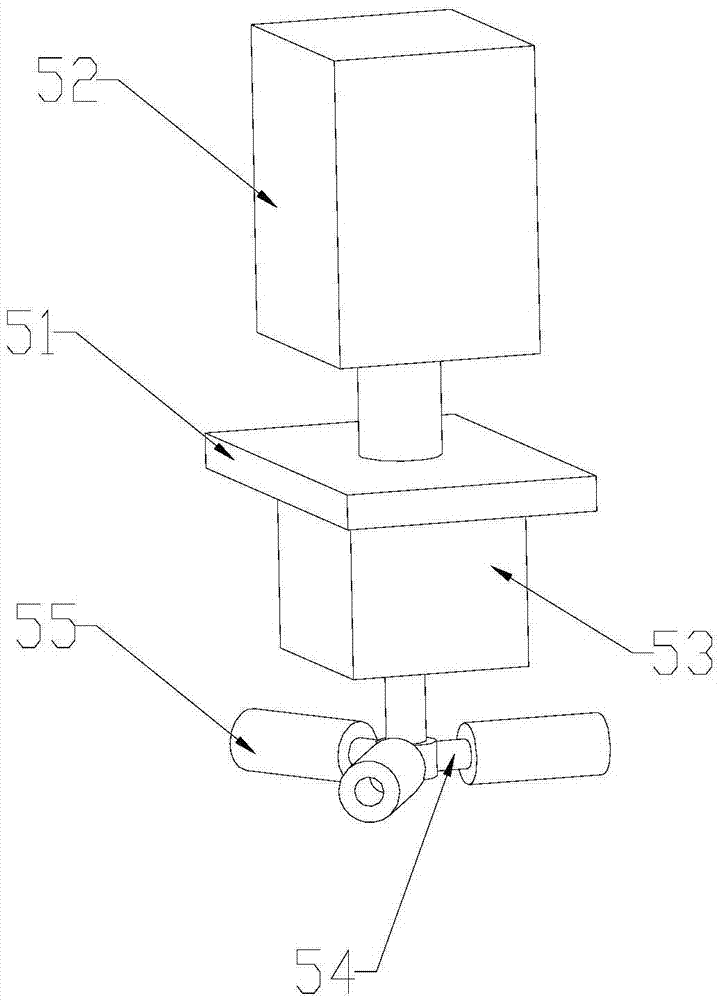

[0018] like Figure 1-6 As shown, it is a biomass fuel pelletizing device of the present invention, which includes a turntable 1, a stepper motor 2 for driving the turntable 1 to rotate, and a series of feeders arranged at intervals of 90 degrees around the central axis of the turntable 1. Material station, extrusion station, pusher station, pelletizing station; four storage basins 3 are arranged on the turntable 1 around its central axis, and the interval angle between any two adjacent storage basins 3 is 90°; the bottom wall of the storage basin 3 is arranged with several forming through-holes 31 around its central axis; control device; the feeding station is provided with a feeding device 4 for inputting materials into the storage basin 3; the extruding station is provided with a first lifting frame 51 above the turntable 1, a piston rod and The fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap