X-ray detector L-shaped box body structure

A ray detector and box body technology, applied in the field of L-shaped box body structure, can solve the problems of production efficiency, low material utilization rate of first pass rate, high requirements for sheet metal processing and welding, easy deformation, etc., and achieve light overall quality , high assembly precision and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0008] The present invention will be described in detail below in conjunction with the drawings and embodiments:

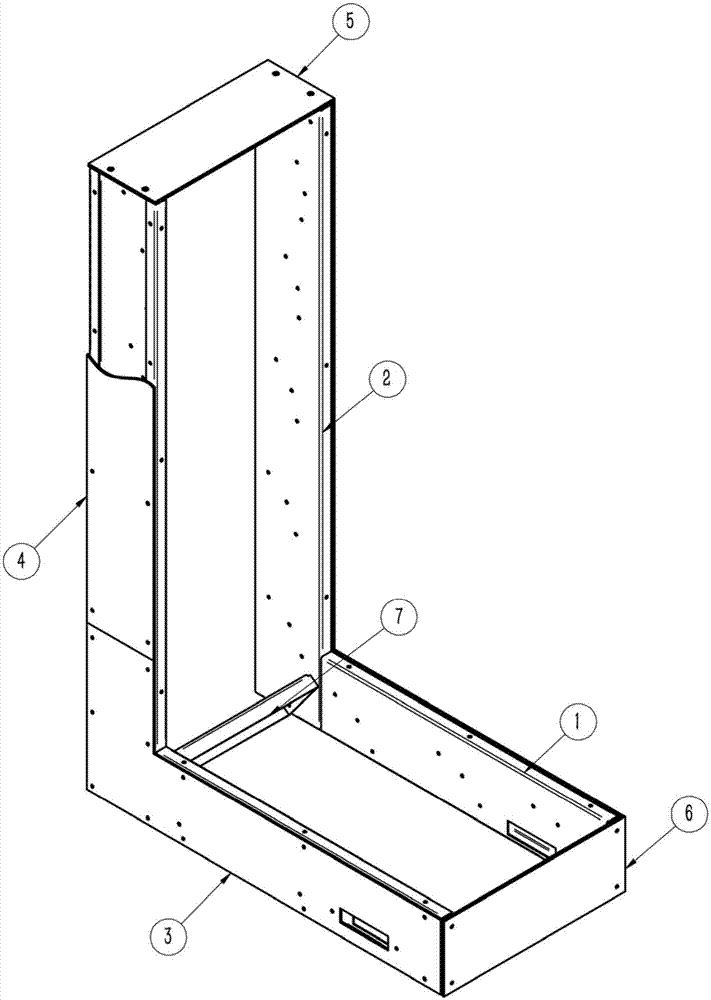

[0009] The L-shaped box body of the X-ray detector is composed of a pair of horizontal box side grids and a pair of vertical box side grids according to the riveting holes, a pair of short L-shaped side plates for bonding lead, and a pair of long The rectangular side plates are riveted into an L-shaped plate assembly, and the two ends of the L-shaped box body are respectively riveted on rectangular plates bonded with lead sheets, and the bent pieces are supported by riveting at the right corners of the L-shaped box body.

[0010] Such as figure 1 As shown, the L-shaped box body of the X-ray detector includes a horizontal box side grid 1 and a vertical box side grid 2 which are respectively bent into a symmetrical box shape by laser cutting; a horizontal box side grid 1 and a vertical box side grid 1 The box side grid 2 is riveted with a short L-shaped side plate 3 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap