Wedge welding gold wire airflow control micro tension mechanism

A technology of airflow control and micro-tension, applied in electrical components, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

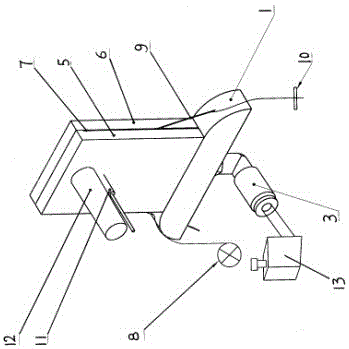

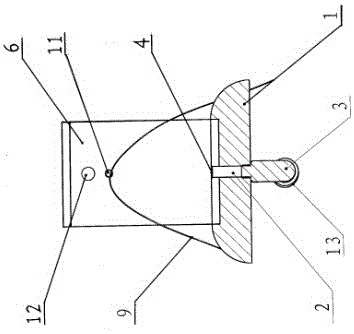

[0011] The present invention is described in detail below in conjunction with accompanying drawing:

[0012] A wedge-welded gold wire airflow control micro-tension mechanism, including a base 1 and an industrial control machine, an air passage 2 is arranged in the base 1, a compressed air blowing port 4 is arranged in the center of the top surface of the base 1, and the compressed air The blowing port 4 communicates with one end of the air circuit 2, and the other end of the air circuit 2 is connected with a compressed air input pipe 3, and a manual regulating valve 13 is arranged on the compressed air input pipe 3. The top end surface of seat 1 is fixedly provided with front baffle plate 5, and the top end surface of base 1 at compressed air blowing port 4 rear sides is fixedly provided with rear baffle plate 6, and between front baffle plate 5 and rear baffle plate 6 is provided with The gold wire lifting seam 7 is provided with a position sensor 11 at the upper end of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com