A glass fiber reinforced ring winding shaft that is convenient for cutting

A technology of reinforcing rings and winding shafts, which is applied in the direction of winding strips, metal processing, and sending objects, which can solve the problems of time-consuming and easy to take out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

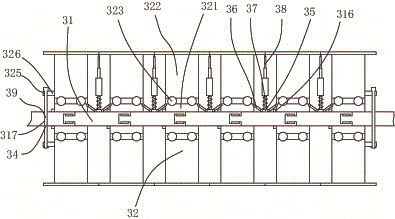

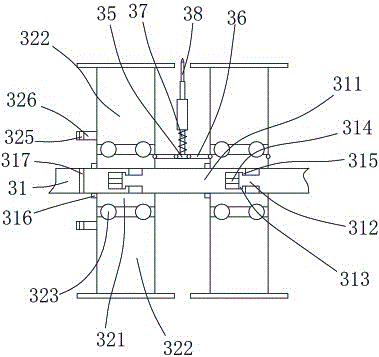

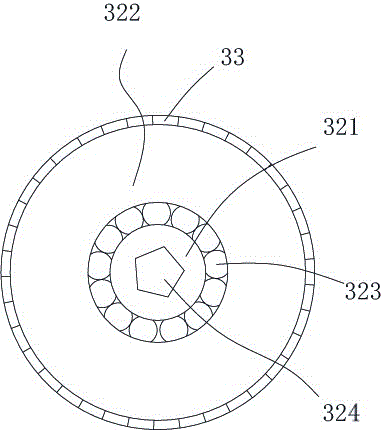

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 4 , a glass fiber reinforced ring winding shaft that is convenient for cutting, including a central shaft 31, the central shaft 31 includes a shaft section 311 that is continuously sleeved front and back, and a first extension rod 312 is provided at one end of the shaft section 311, so The end of the first extending rod 312 is provided with a sliding block 313 with a non-circular section, and the other end of the shaft section 311 is provided with a sliding groove 314. The sliding block 313 of the rear shaft section 311 and the front shaft section 311 The sliding groove 314 is matched, and the opening of the sliding groove 314 is provided with a protruding ring 315 to prevent the sliding block 313 from slipping out. The central shaft 31 is sleeved with a number of annular cylinders 32, and the cylinders 32 include inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com