A fully automatic clothes hanger forming and welding hook integrated machine

A forming welding and all-in-one machine technology, which is applied in applications, home appliances, manufacturing tools, etc., can solve the problems of low production efficiency, waste of resources, and inability to use, and achieve the effects of high automation, cost saving, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

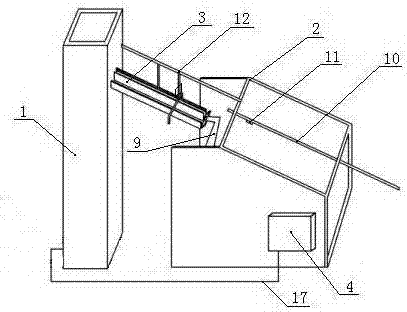

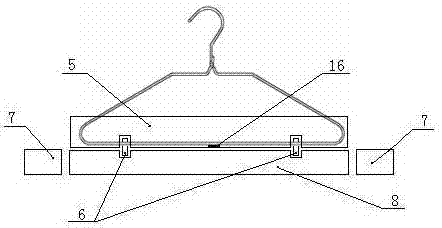

[0025] As shown in the figure, in the figure 1, clothes hanger forming machine, 2, clothes hanger welding hook machine, 3, slideway, 4, control device, 5, fixing device, 6, spot welding device, 7, wire feeding device II, 8, Hanger bottom hook forming device, 9. Manipulator, 10. Material receiving rack, 11. Waste detection device, 12. Bracket, 13. Guide rod, 14. Knife device, 15. Recessed part, 16. Induction probe, 17. External wiring;

[0026] Such as figure 1 As shown, the fully automatic clothes hanger forming and welding hook integrated machine is composed of a clothes hanger forming machine 1, a clothes hanger welding hook machine 2, a slideway 3, and a control device 4.

[0027] The hanger forming machine includes a frame 1, a driving device 1, a wire feeding device 1, a hanger body forming device, a ticking device, a twisting device and a mold p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com