Biodegradable polyurethane elastomer and preparation method thereof

A polyurethane elastomer, biodegradable technology, used in the synthesis and application of new chemical materials, can solve the problems of high melting point, limited application range, etc., achieve good mechanical properties, avoid high temperature degradation, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

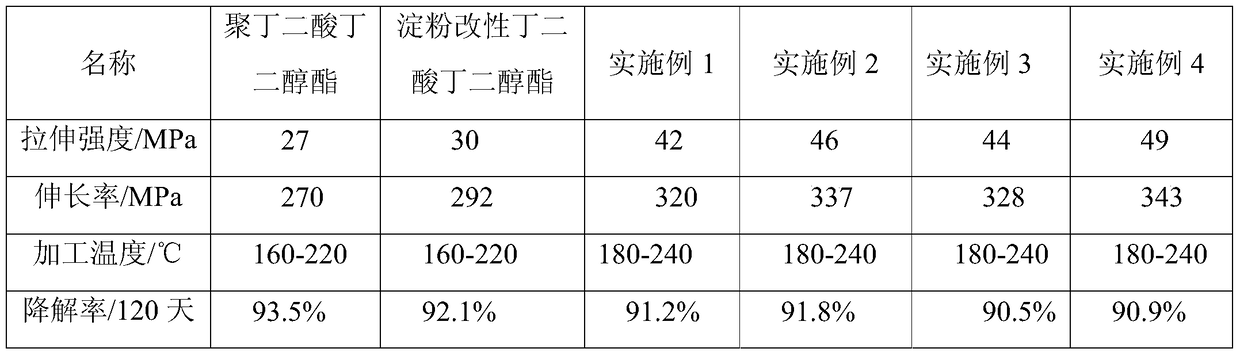

Examples

Example Embodiment

[0030] Example 1

[0031] Add polybutylene succinate: 5000kg, 1010: 9.3kg, 1076: 9.3kg, triphenyl phosphite: 9.3kg, E wax: 18.6kg, and stannous octoate: 1050g to the polyester high tank. Stir uniformly, add 3345kg of diphenylmethane diisocyanate to the high isocyanate tank, add 913kg of 1,4-butanediol to the high tank of the chain extender, set the flow rate of component A, component B and component C. It is driven into the twin-screw casting machine from the high slot, granulated by the underwater pelletizer, dehydrated, dried and vulcanized to obtain the product.

Example Embodiment

[0032] Example 2

[0033] Add polybutylene succinate: 5000kg, 1010: 10.9kg, 1076: 10.9kg, triphenyl phosphite: 10.9kg, 69 wax: 10kg, oleic acid amide 11.8kg, caprylic acid in sequence into the polyester high tank Stannous: 990g, stir evenly, add 4481kg of diphenylmethane diisocyanate to the high isocyanate tank, add 1388kg of 1,4-butanediol to the high tank of the chain extender, and combine the components A, B and C Set the flow rate, feed into the twin-screw casting machine from the high slot, granulate by the underwater pelletizer, dehydrate, dry and vulcanize to obtain the product.

Example Embodiment

[0034] Example 3

[0035] Add polybutylene adipate: 5000kg, 1010: 9.3kg, 1076: 9.3kg, triphenyl phosphite: 9.3kg, E wax: 13.6kg, erucamide: 5kg in sequence to the polyester high tank, Stannous octoate: 1050g, stir evenly, add 3345kg of diphenylmethane diisocyanate to the high tank of isocyanate, add 913kg of 1,4-butanediol to the high tank of chain extender, and combine A component, B component and C group Set the flow rate separately, feed into the twin-screw casting machine from the high slot, granulate by the underwater pelletizer, dehydrate, dry and vulcanize to obtain the product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap