A helicopter ground handling vehicle

A technology for helicopters and trucks, applied in the field of transportation machinery, can solve problems such as hydraulic oil leakage, large volume, and failure of push rods, and achieve the effects of preventing sudden failure, reducing volume, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide a helicopter ground transport vehicle, which can be applied to small-sized helicopters with a small space at the bottom of the belly, so as to reduce the workload of operators.

[0030] In order to make those skilled in the art better understand the technical solution of the present invention, the helicopter ground transport vehicle designed by the invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

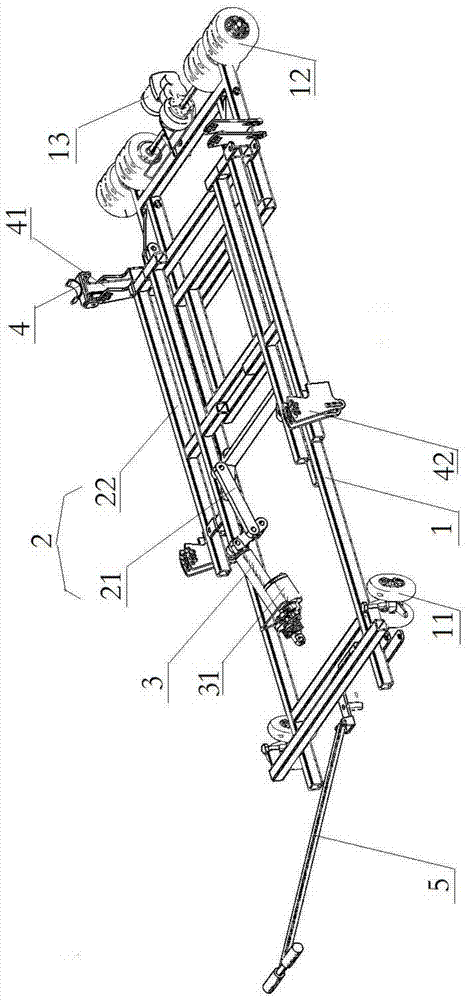

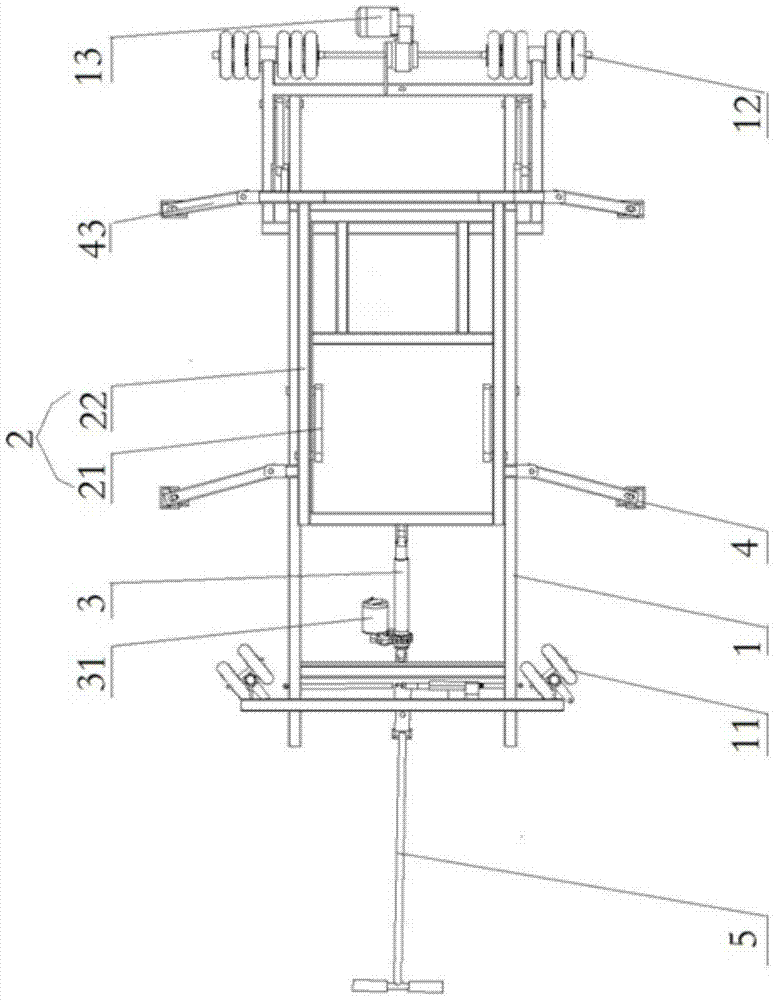

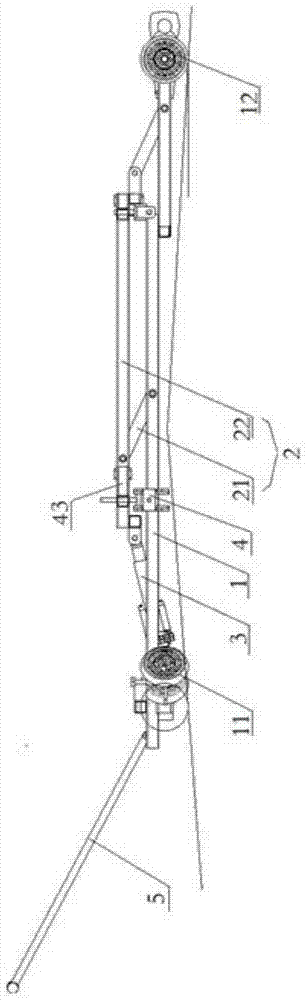

[0031] like figure 1 Shown is a schematic structural view of an embodiment of the helicopter ground transport vehicle of the present invention. The helicopter ground truck that the present invention provides has a chassis 1, plays the effect of supporting, front wheel 11 and rear wheel 12 are installed respectively at the front and rear ends of chassis 1, generally, front wheel 11 and rear wheel 12 are at least Each has two wheel sets, and the wheel sets of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com