Electrically-driven membrane desalting unit and water treatment method using same

An electric drive and desalination technology, which is applied in the field of water treatment, can solve the problems of water leakage between membranes, lack of protection, and large floor space, etc., and achieve the effects of prolonging equipment life, reducing space leakage, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

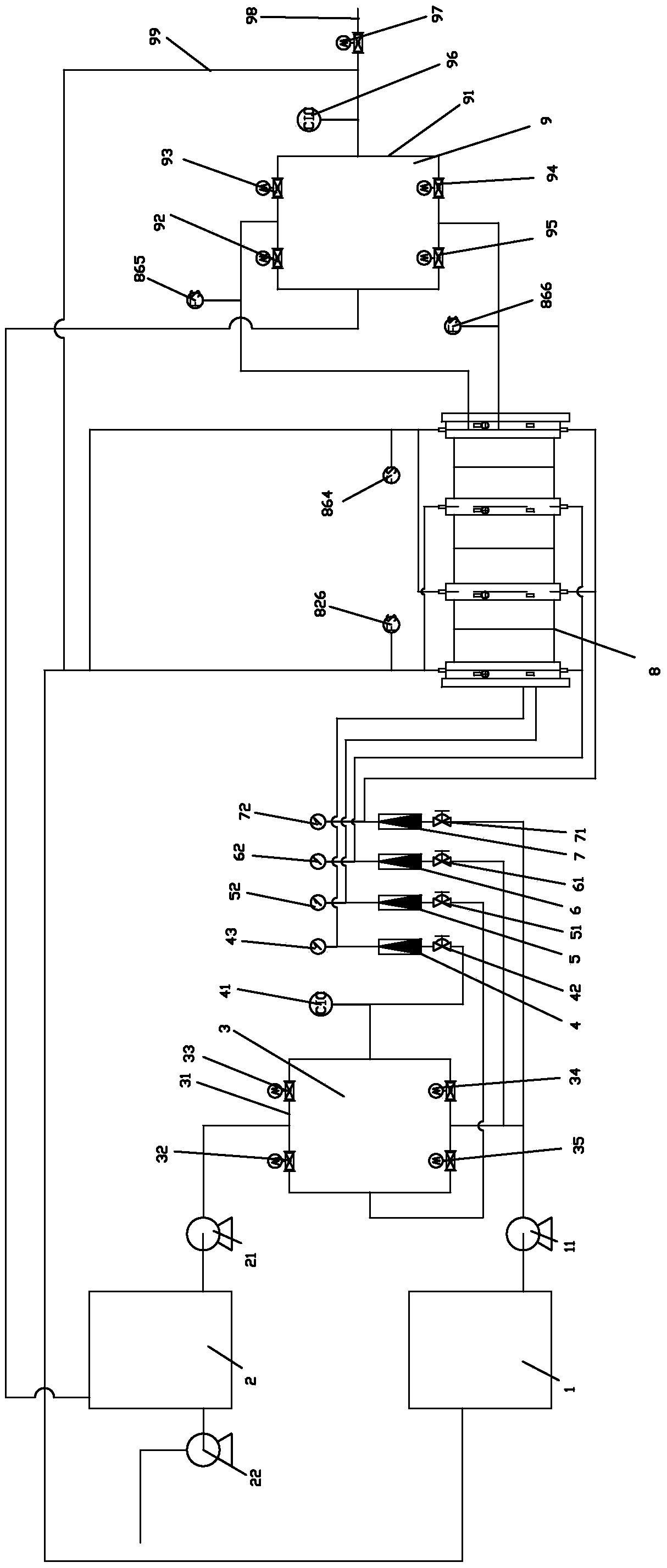

[0083] Such as Figure 1-Figure 4 As shown, an electric-driven membrane desalination unit includes raw water tank 1, concentrated water circulation tank 2, inlet valve group 3, raw water flowmeter 4, concentrated water flowmeter 5, polar water flowmeter I6 and polar water flowmeter II7, Multi-stage membrane stack device 8 and outlet valve group 9,

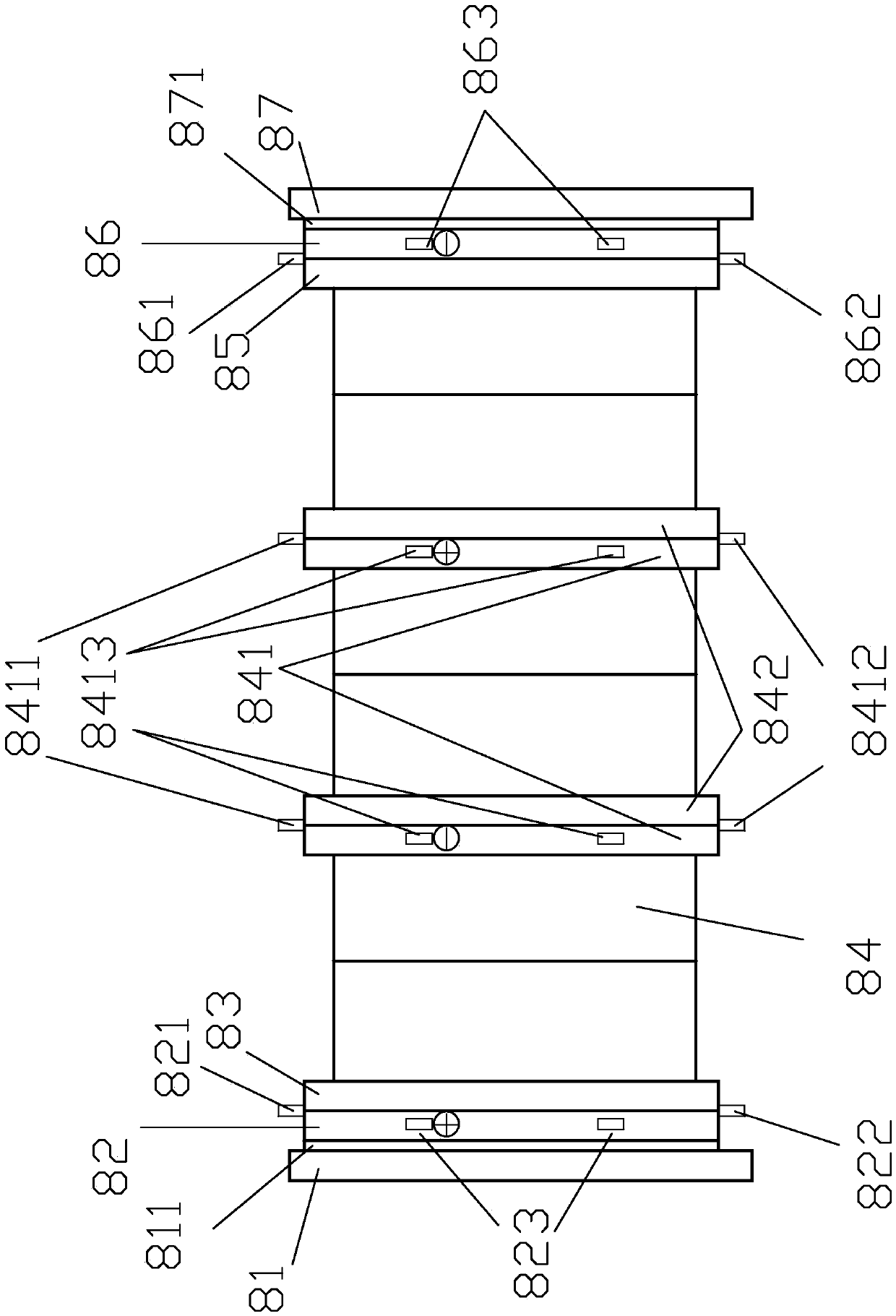

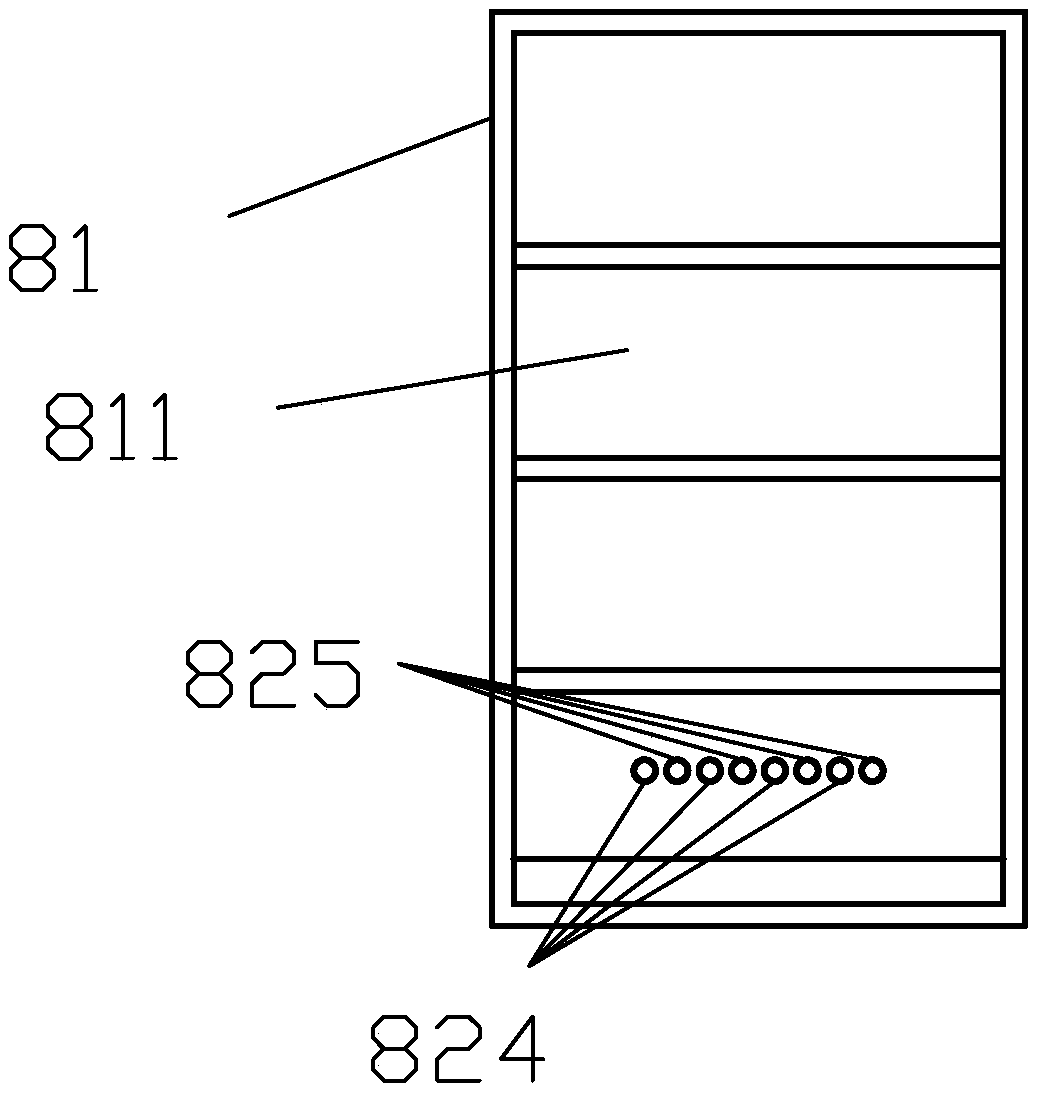

[0084] The multi-stage membrane stack device 8 includes a locking frame I81, a water distribution plate I82, a porous plate I83, a third-stage membrane stack 84, a porous plate II85, a water distribution plate II86, and a locking frame II87 connected in sequence. The membrane stacks of the latter stage are connected sequentially through the common electrode plate 841 and the porous plate III 842,

[0085] A space for accommodating electrodes is provided between the water distribution plate I82 and the perforated plate I83, and the upper part of the connection between the water distribution plate I82 and the perforated plate I83 is...

Embodiment 2

[0117] A water treatment method using the electrically driven membrane desalination unit has the following steps:

[0118] S1. The inlet valve I32 and the inlet valve III34 are opened, the inlet valve II33 and the inlet valve IV35 are closed, the outlet valve I92 and the outlet valve III94 are opened, the outlet valve II93 and the outlet valve The valve IV 95 is closed, the water production valve 97 is closed, and after the preset time I is reached, the two adjacent electrodes are respectively connected to the positive pole and the negative pole of the power supply,

[0119] The raw water enters the multi-stage membrane stack device 8 through the raw water pump 11, the inlet valve III34, the raw water detection unit 41, the diaphragm valve I42, the raw water flowmeter 4 and the electric contact pressure gauge I43 process to obtain produced water, and the produced water passes through the outlet water flow switch II 866 and the outlet valve III 94 to the produced water detectio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap