A high critical current density nb 3 The preparation method of sn superconducting wire rod

A superconducting wire, current density technology, applied in cable/conductor manufacturing, usage of superconducting elements, superconducting devices, etc., can solve the problems of affecting the current carrying capacity of the wire, the insufficient response of the core wire, etc., and achieve low hysteresis. Effects of loss, Jc increase, and critical current density increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

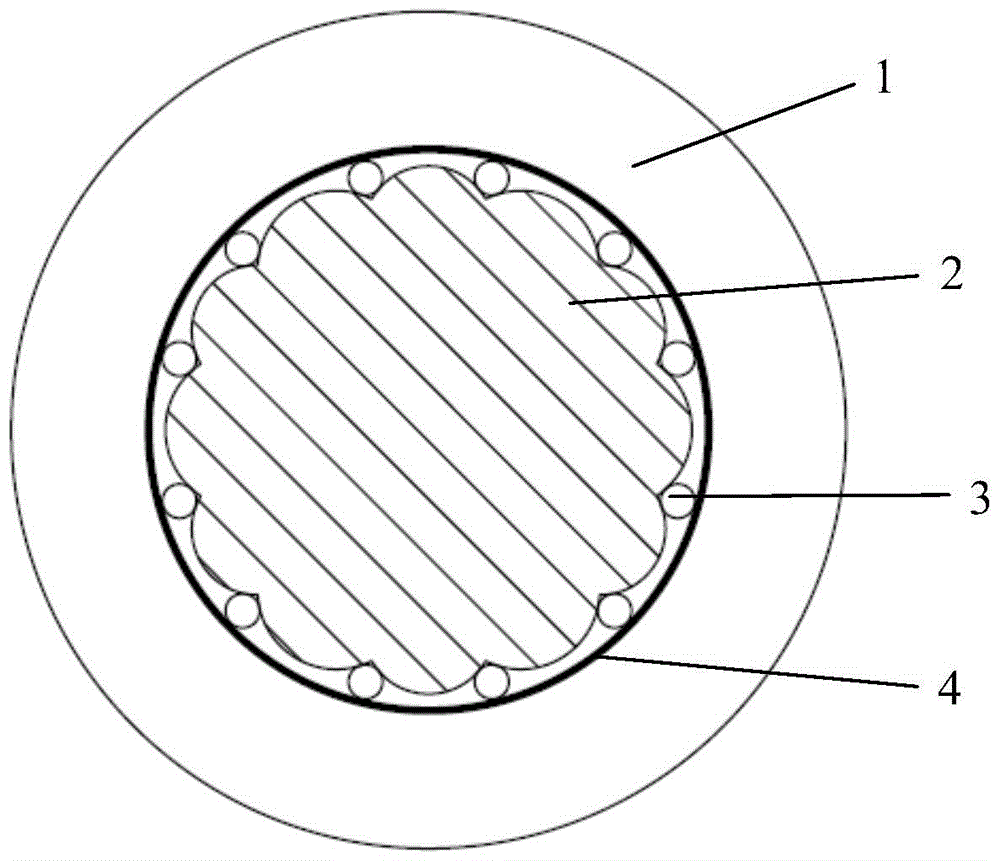

[0026] A kind of high critical current density Nb of the present invention 3 The preparation method of Sn superconducting wire specifically comprises the following steps:

[0027] Step 1: Select an oxygen-free copper ingot with a diameter of 200-300mm and a length of 500-800mm as the ingot, and use the method of deep hole drilling to drill 4-5 layers evenly distributed along the length of the ingot. A total of 100-250 ingots with a diameter of 9-15mm through holes to obtain porous copper ingots;

[0028] Step 2: For the porous copper ingot obtained in step 1, first use a metal cleaner to remove surface oil, then use a nitric acid solution with a volume concentration of 25% to 40% to clean the inner hole and surface, and insert the cleaned Nb rod into the cleaned porous copper ingot. In the through hole of the copper ingot, add a copper cover to both ends of the porous copper ingot and seal it with an electron beam. The sealing welding current is 50-150mA, and the vacuum degre...

Embodiment 1

[0034] Step 1: Select an oxygen-free copper ingot with a diameter of 200mm and a length of 600mm as the ingot, and use the method of deep hole drilling to drill a total of 100 through holes with a diameter of 9mm evenly distributed in 4 layers along the length of the ingot to obtain porous copper. ingot;

[0035] Step 2: For the porous copper ingot obtained in step 1, first use a metal cleaner to remove surface oil, then clean the inner hole and surface with a nitric acid solution with a volume concentration of 30%, and insert the cleaned Nb rod into the cleaned porous copper ingot. In the hole, add copper caps on both ends of the porous copper ingot and seal welding with electron beam, the sealing welding current is 90mA, and the vacuum degree is not greater than 10 -2 Pa, get CuNb multi-core sheath;

[0036] Step 3: Heat the CuNb multi-core sheath obtained in step 2 to 500°C, heat it for 2 hours and then extrude it to obtain a multi-core CuNb composite rod with a diameter o...

Embodiment 2

[0041] Step 1: Select an oxygen-free copper ingot with a diameter of 260mm and a length of 720mm as the ingot, and use the method of deep hole drilling to drill a total of 150 through holes with a diameter of 11mm evenly distributed in 4 layers along the length of the ingot to obtain porous copper. ingot;

[0042] Step 2: For the porous copper ingot obtained in step 1, first use a metal cleaner to remove surface oil, then clean the inner hole and surface with a nitric acid solution with a volume concentration of 25%, and insert the cleaned Nb rod into the cleaned porous copper ingot. In the hole, add copper caps to both ends of the porous copper ingot and seal it with electron beams. The welding current is 50mA, and the vacuum degree is not greater than 10 -2 Pa, get CuNb multi-core sheath;

[0043] Step 3: Heat the CuNb multi-core sheath obtained in step 2 to 600°C, heat it for 1 hour and then extrude it to obtain a multi-core CuNb composite rod with a diameter of 70mm, stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com