Permanent magnet coupling stepless speed adjusting device for high-power and high-rotating-speed motor

A technology of permanent magnet coupling and stepless speed regulation, applied in transmission, gear transmission, mechanical equipment, etc., can solve the problems of large heating of conductor rotor, decrease in proportion, waste of energy, etc. The effect of reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

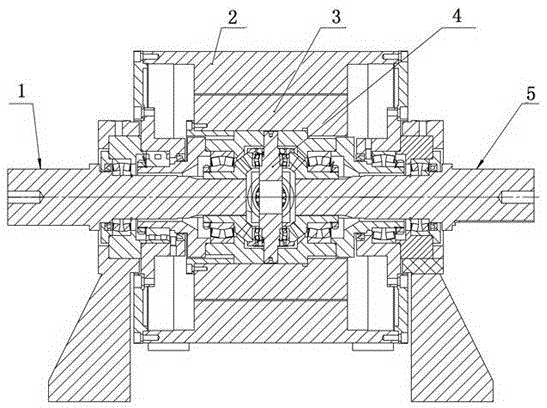

[0010] Such as figure 1 The shown invention includes an output shaft (1), a stator (2) and a rotor (3) of a permanent magnet synchronous motor, an NGW planetary mechanism (4), and an input shaft (5).

[0011] The structure of the present invention cooperates with the electric control switch and can be operated by addition or subtraction according to the needs of working conditions. Addition operation is a low-voltage frequency converter to adjust the speed of the permanent magnet synchronous motor. Running by subtraction is to use the inverter to feed electricity back to the grid, and the speed can be adjusted by controlling the feedback power.

[0012] The structure of this embodiment uses the NGW planetary mechanism with a speed ratio of 1:3 to 6, uses the sun gear output of the planetary mechanism, and connects the main motor and the permanent magnet synchronous motor with the planetary carrier and the internal gear respectively, for addition or subtraction input, suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com