Emulsion composition and milk drink

A technology of emulsified composition and milk beverage, which is applied in milk substitutes, dairy products, food science, etc., and can solve problems such as difficult to reproduce taste, light taste, thick feeling or insufficient milk flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

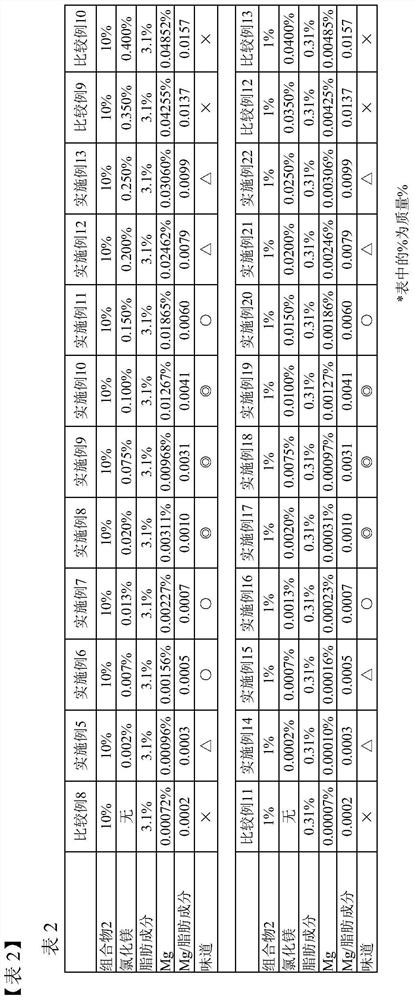

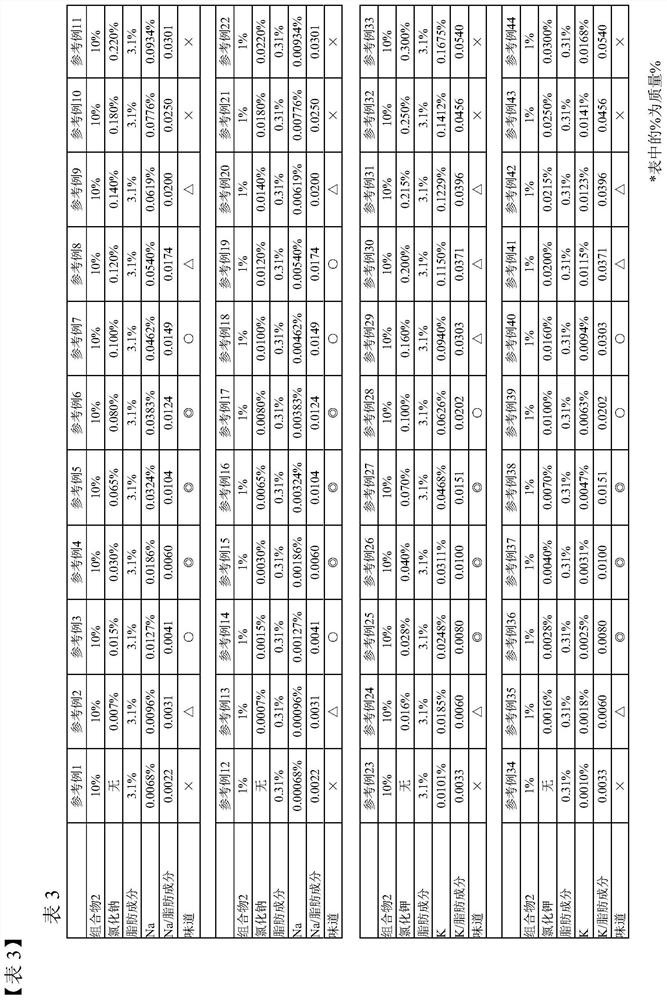

[0165] The present invention will be described more specifically by way of examples, but the present invention is not limited to the description of the following examples unless the gist is exceeded.

[0166] Details of (A), (B), (D), and (E) components used in the following examples and comparative examples are as follows. In addition, whey mineral is made into (C)component.

[0167] (B), (C), and (D) components correspond to a magnesium material.

[0168]

[0169] Polysaccharide 1: Starch hydrolyzate (dextrose equivalent: 23)

[0170] Product name "Nisshoku Branch-Oligo" Japanese food processing and manufacturing

[0171] Polysaccharide 2: Starch hydrolyzate

[0172] Product name "Nisshoku cleartose #56" Japanese food processing and manufacturing

[0173]

[0174] Fragrance 1: Product name "Milkrich ベース L" manufactured by Kyodo Dairy Co., Ltd.

[0175] (Magnesium content: 0.04% by mass)

[0176] Fragrance 2: Product name "ミルクコンクベースKB" manufactured by Kyodo Dairy In...

manufacture example 1

[0189] 12 g of sodium caseinate, 13 g of sucrose fatty acid ester (carbon number of fatty acid = 16 and 18, monoester content = 77% by mass), 13 g of polyglycerin fatty acid ester (Ryoto (registered trademark) Polyglyester S-10D, Mitsubishi Chemical Foods Co., Ltd.) 3g and succinic acid monoglyceride (carbon number of fatty acids = 16 and 18) 2g of water phase 300g was heated to 65°C, and then put in non-fermented cream cheese made of milk and whipped cream (Total solid content: 61% by mass, milk fat content: 51% by mass) 600 g was pre-emulsified at 8000 rpm using a homomixer for 5 minutes. Then add water, adjust the total amount to 1000g, use a high-pressure homogenizer to homogenize twice at 65°C and 20MPa, fill it into a container, and sterilize at 90°C for 15 minutes to obtain composition 1 (fat component: 31 % by mass, Mg: 0.0072% by mass, Na: 0.068% by mass, K: 0.101% by mass) (hereinafter referred to as "composition 1").

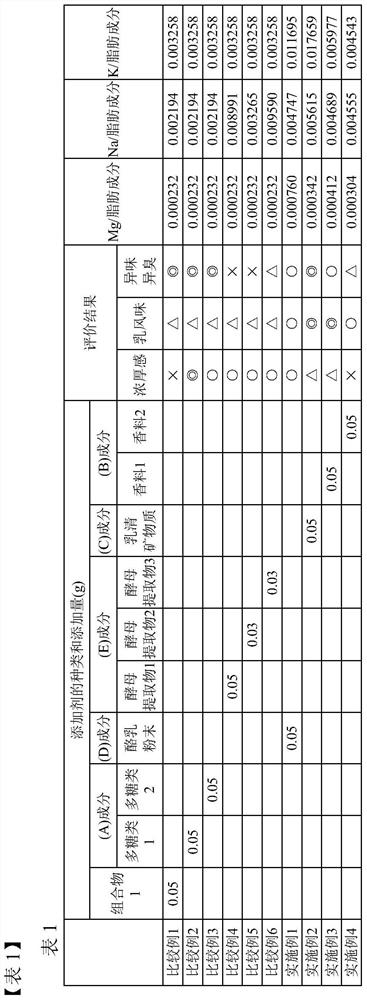

Embodiment 1~4、 comparative example 1~6

[0191] 1.5 g of instant coffee as a coffee extract, 0.28 g of composition 1 (containing 60% by mass of cream cheese) obtained in Production Example 1, and 0.056 g of baking soda were mixed and dissolved in water, and Table 1 was added to the obtained liquid. After the additives shown in 1 were fully mixed and dissolved, water was further added to make the total amount 100 g, and the emulsified composition (=milk drink) of the present invention was obtained.

[0192] About the obtained milk drink, it evaluated by the following evaluation criteria after each sampled by 4 panel discussion participants at normal temperature. The results are shown in Table 1. From the results in Table 1, it can be seen that it is important to contain Mg at a constant mass ratio to lipid, especially for milk flavor.

[0193]

[0194] ◎: thick feeling

[0195] ○: Slightly dense

[0196] △: Slightly weak taste

[0197] ×: light taste

[0198]

[0199] ◎: Strong milk flavor

[0200] ○: Milky ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com