A brick bundling machine

A technology for baling machines and tiles, which is applied to the parts of bundling machinery, types of packaging items, special packaging items, etc. It can solve problems such as low efficiency, wrong counting, and roughness, and achieve the effect of improving efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

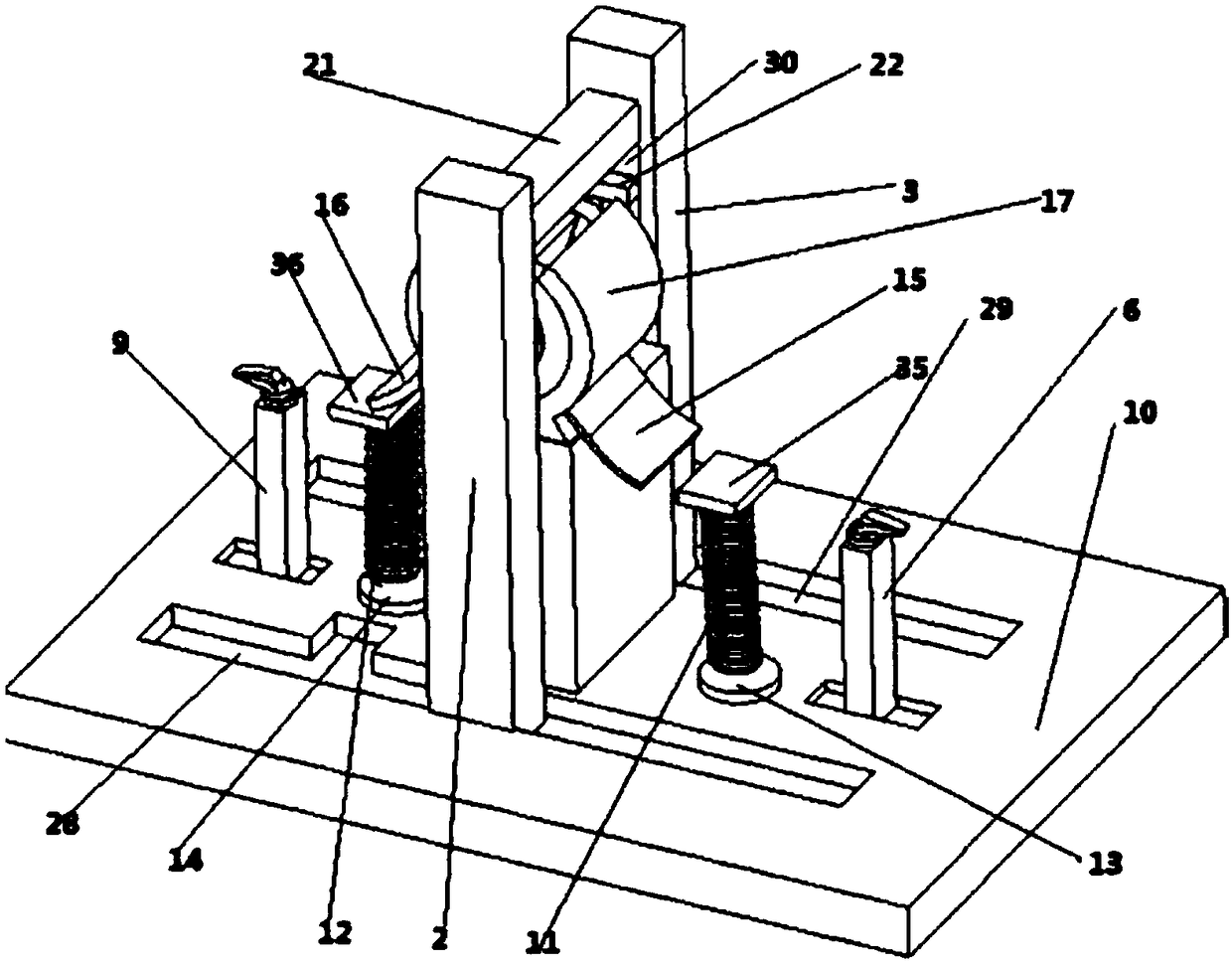

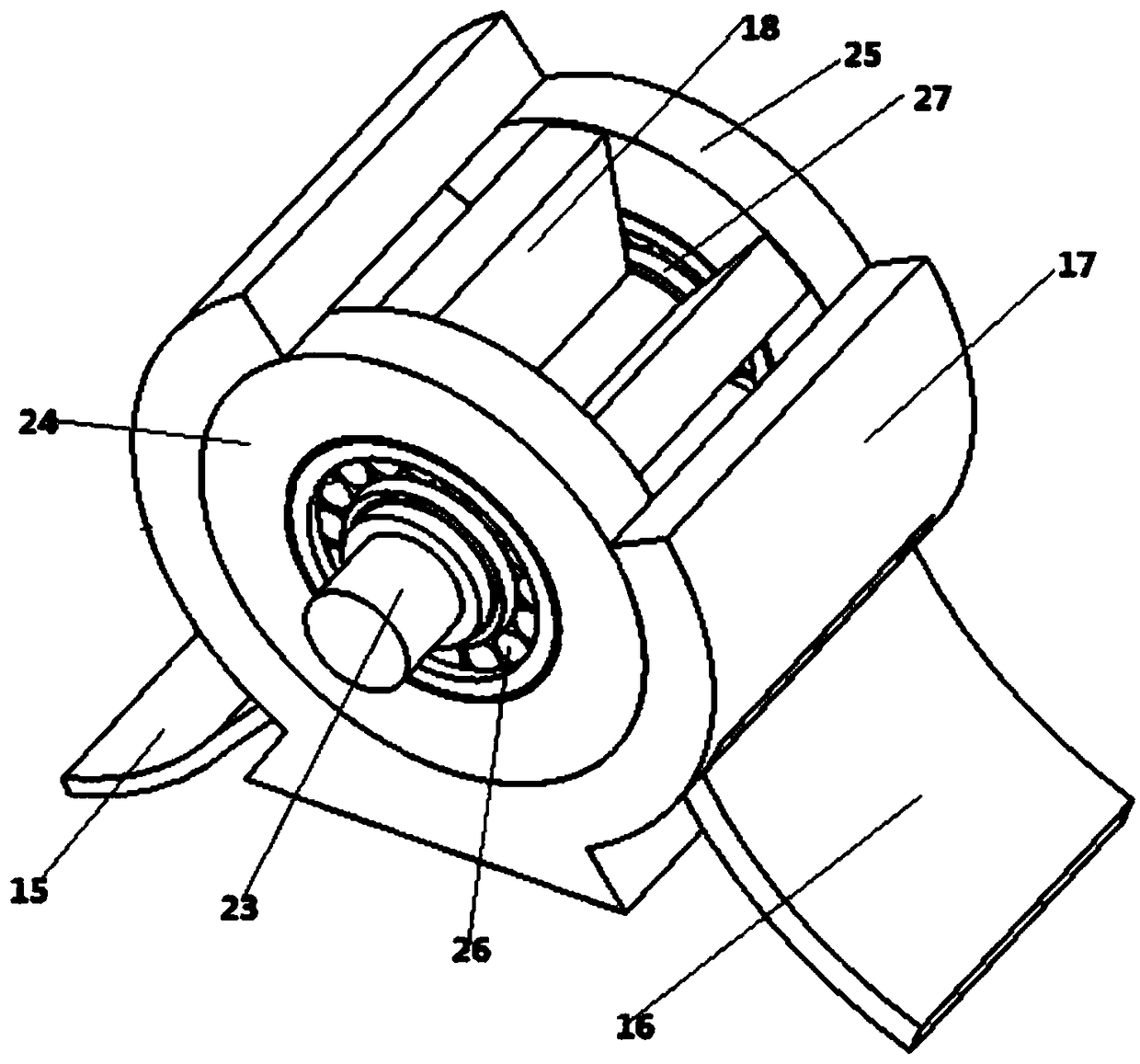

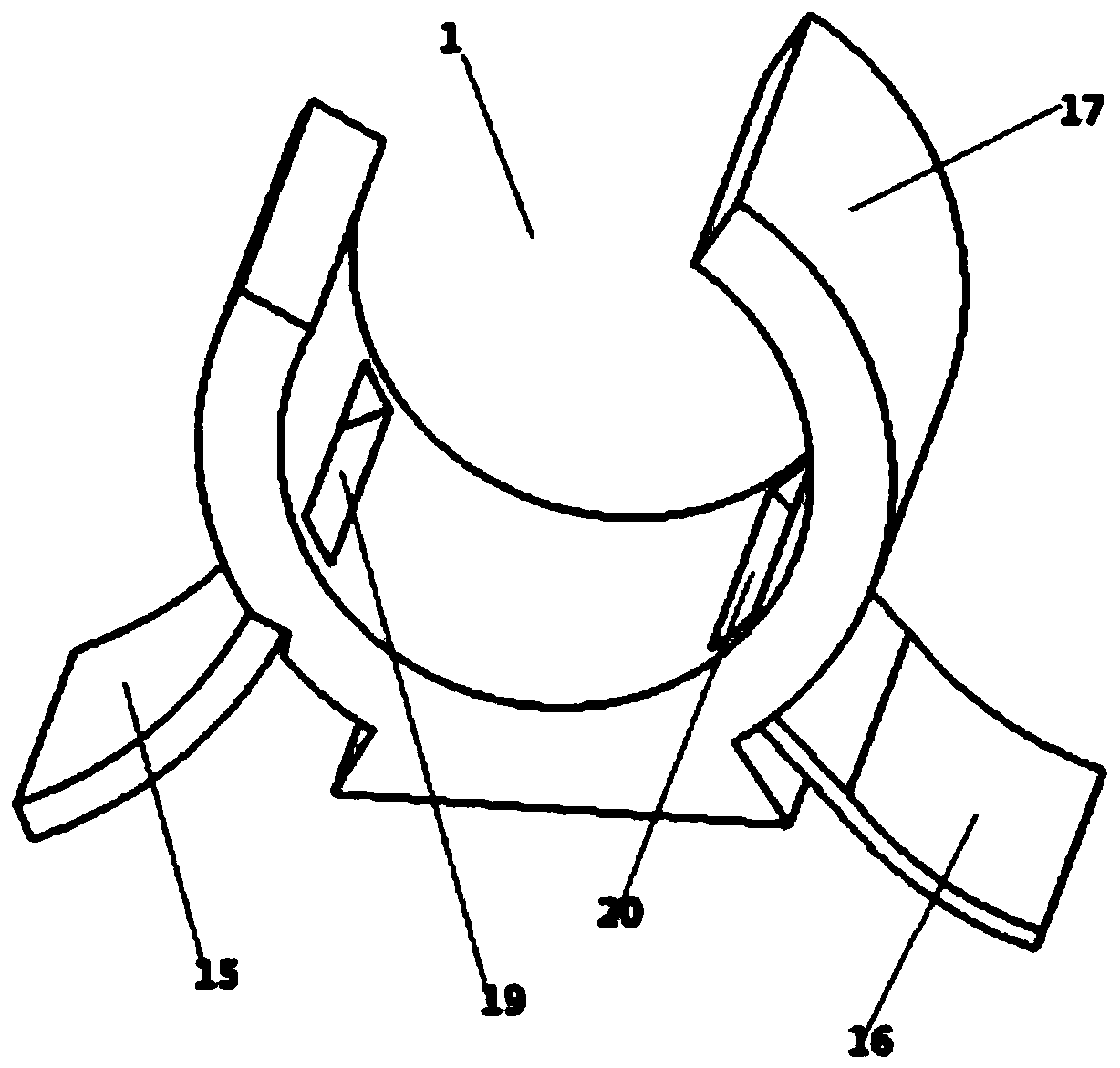

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

[0018] in the attached figure 1 In the process, the messy tiles are put into the brick sorting machine through the feeding port 1, and as the rotor 18 of the brick sorting machine rotates, the blades on the rotor rotate together with the tiles, and finally the tiles pass through the brick outlet on the stator 17 of the brick sorting machine. 19 and brick outlet 2 20 slide out, and slide down on spring tray 1 35 and spring tray 2 36. The heights of the two brick outlets from the plane of the base 10 are different, and the height of brick outlet 1 19 is high, and the inclination angle with the horizontal plane is small , the tiles with the smooth side facing down slide out; the height of the brick outlet 220 is low, and the inclination angle with the horizontal plane is large, and the tiles with the rough side down slide out. When the load of either one of spring pallet one 35 or spring pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com