Clean production process of folic acid

A production process and clean technology, applied in the field of folic acid clean production process, can solve problems such as unfavorable human health and low yield, and achieve the effects of saving raw materials, improving purity, and saving steps and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

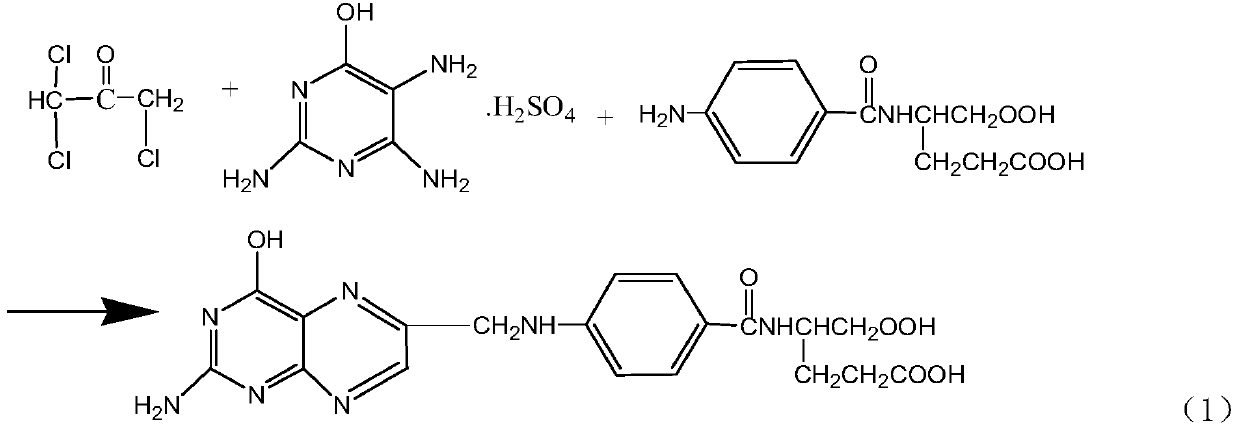

[0024] In the present invention, the clean production process of folic acid specifically comprises the following steps:

[0025] Step 1, the preparation of crude product,

[0026] Add 2,4,5-triamino-6-hydroxypyrimidine sulfate, p-aminobenzoyl glutamic acid and trichloroacetone in turn to the four-necked flask, the molar ratio of the three is 1:1:1, and turn on the stirrer , the reaction raw materials in the flask are stirred, after the three are mixed evenly, add alkaline sodium hydroxide liquid, the add-on of alkaline sodium hydroxide is 10% of raw material gross weight, the alkaline sodium hydroxide here is A solution with a mass fraction of 30% was reacted under alkaline conditions, the reaction temperature was 50° C., the pH was 2.0, and the reaction time was 10 hours to prepare a crude product;

[0027] Step 2, add sodium pyrosulfite to the crude product, the amount of sodium pyrosulfite added is 10% of the weight of the crude product, stir at 38°C for 0.5h, add dropwise...

Embodiment 2

[0034] In the present invention, the clean production process of folic acid specifically comprises the following steps:

[0035] Step 1, the preparation of crude product,

[0036] Add 2,4,5-triamino-6-hydroxypyrimidine sulfate, p-aminobenzoyl glutamic acid and trichloroacetone in turn to the four-necked flask, the molar ratio of the three is 1:1:1, and turn on the stirrer , the reaction raw materials in the flask are stirred, after the three are mixed evenly, add alkaline sodium hydroxide liquid, the add-on of alkaline sodium hydroxide is 10% of raw material gross weight, the alkaline sodium hydroxide here is A solution with a mass fraction of 30% was reacted under alkaline conditions, the reaction temperature was 55° C., the pH was 3.0, and the reaction time was 9 hours to prepare a crude product;

[0037] Step 2, add sodium pyrosulfite to the crude product, the amount of sodium pyrosulfite added is 10% of the weight of the crude product, stir at 38°C for 0.5h, add dropwise ...

Embodiment 3

[0044] In the present invention, the clean production process of folic acid specifically comprises the following steps:

[0045] Step 1, the preparation of crude product,

[0046] Add 2,4,5-triamino-6-hydroxypyrimidine sulfate, p-aminobenzoyl glutamic acid and trichloroacetone in turn to the four-necked flask, the molar ratio of the three is 1:1:1, and turn on the stirrer , the reaction raw materials in the flask are stirred, after the three are mixed evenly, add alkaline sodium hydroxide liquid, the add-on of alkaline sodium hydroxide is 10% of raw material gross weight, the alkaline sodium hydroxide here is A solution with a mass fraction of 30% was reacted under alkaline conditions, the reaction temperature was 60° C., the pH was 3.5, and the reaction time was 8 hours to prepare a crude product;

[0047] Step 2, add sodium pyrosulfite to the crude product, the amount of sodium pyrosulfite added is 10% of the weight of the crude product, stir at 40°C for 0.5h, add dropwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com