Method for reproducing high-end engine cylinder material with high quality by utilizing aluminium skimmings

An engine block and high-quality technology, which is applied in the field of high-end engine block materials and high-end engine materials with high-quality regeneration of aluminum shavings, can solve problems such as undiscovered patent literature reports, reduce burning loss, reduce production costs, and ensure The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

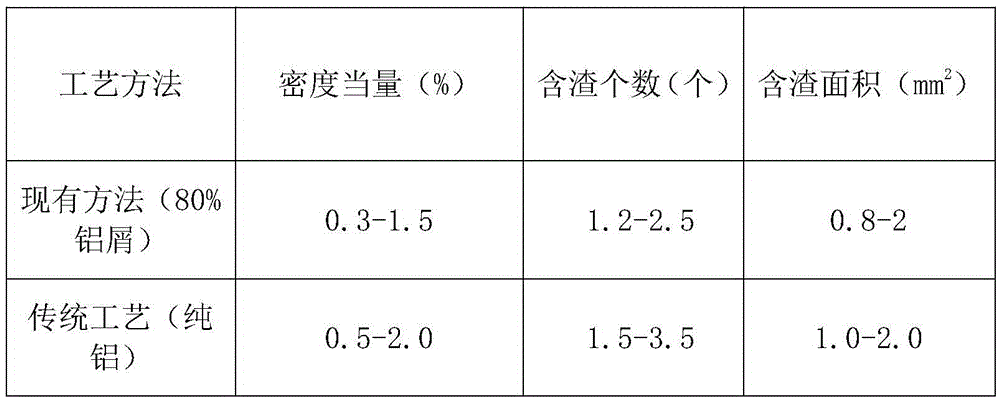

Image

Examples

Embodiment Construction

[0028] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

[0029] A method for regenerating high-end engine block materials with high-quality aluminum shavings, the specific steps are as follows:

[0030] (1) Put 4t of pure aluminum ingots into a 30t melting furnace and melt to 680-700°C;

[0031] ⑵Start the aluminum chip feeding device, the aluminum chips go through the hopper into the crusher, through the drying machine, magnetic separation equipment, drying kiln, and into the melting furnace. Under the agitation of the mechanical circulation pump, the aluminum chips enter the molten aluminum and melt until 24t of aluminum chips are added. The temperature in the drying kiln is controlled at 200-400°C;

[0032] (3) After adding the aluminum chips, adjust the temperature of the molten aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com