Waste residue removal pressurization connecting device for septic tank

A technology for septic tanks and connectors, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., which can solve the problems of increasing costs, difficulties in cleaning septic tanks, slag discharge blockage in septic tanks or gas treatment tanks, etc. problems to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

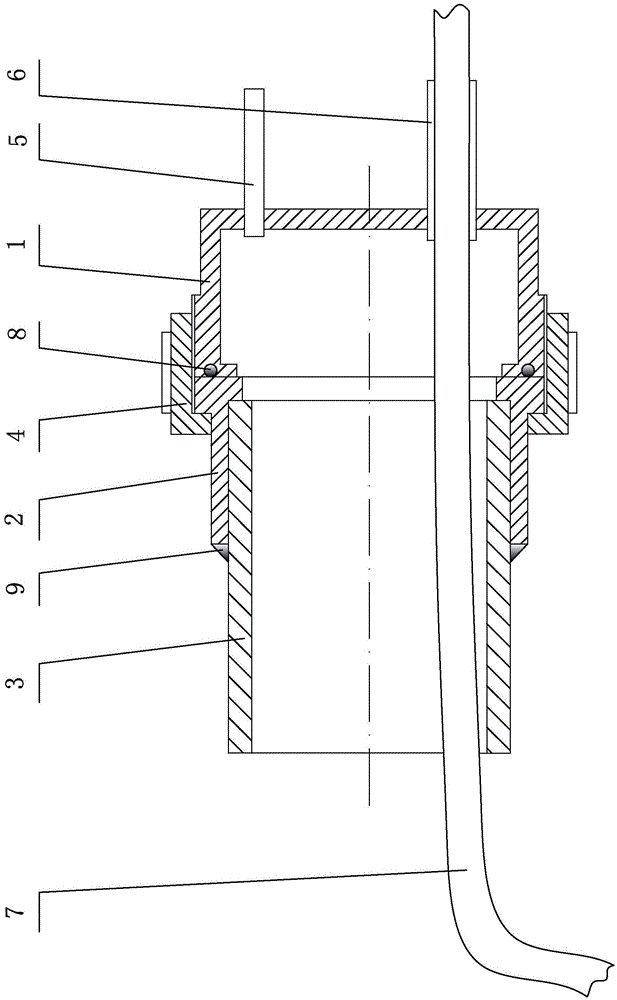

[0011] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0012] The technical solution of the septic tank waste residue cleaning pressurized connector of the present invention includes a movable joint composed of a cover 1 and a sleeve 2, the sleeve 2 is inserted into the port of the septic tank feed pipe 3, and the sleeve 2 The spigot of the inner port is positioned, and the positioned casing 2 and the septic tank feed pipe 3 are bonded and fixed with glue 9; The threads are screwed together and tightened, so that the port of sleeve cover 1 is docked with the port of casing 2, and a rubber sealing ring 8 is arranged in the sealing groove of the port of sleeve cover 1, and the rubber sealing ring 8 is compressed and sealed between the sleeve cover 1 and the casing 2 between the docking surfaces, such as figure 1 shown.

[0013] The upper part of the cover surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com