Programmed LED light source controller

A technology of LED light source and controller, which is applied in the field of programmable LED light source controller, can solve the problems of reduced lifespan, single function, and large heat generation, and achieve good heat dissipation performance, good image contrast, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

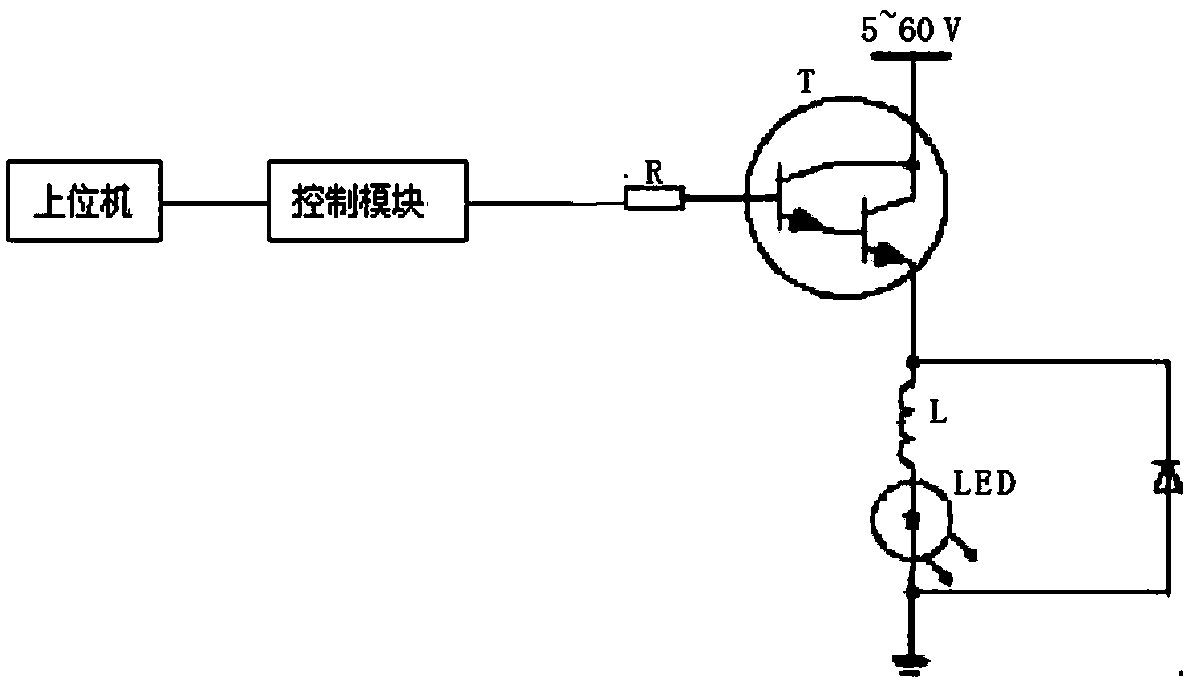

[0014] A program-controlled LED light source controller, which is composed of a connected drive module and a control module, and a host computer; wherein, the drive module uses a power Darlington tube TIP125 as a drive, a resistor is connected in series with the gate, and the collector is connected to the power supply voltage. The emitter is connected in series with the LED light source, and a Schottky diode is connected in parallel at the LED light source; among them, TIP125 is a PNP transistor with a maximum collector-base voltage of 60V; a maximum collector-emitter voltage of 60V; a maximum base current of 0.1 A; The maximum emitter current is 5A, and the emitter peak current is 8A, which can almost meet the requirements of all current high-power LED drivers. The LED in the figure can be one LED or multiple LEDs connected in series. Schottky diodes play the role of freewheeling. In order to ensure the stability of the illumination of the light source to meet the image acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com