Low saturated water-in-oil oil and fat composition

A technology of oil composition and mixture, which is applied in the directions of edible oil/fat, edible oil/fat phase, food science, etc., and can solve the problem of high dosage of synthetic emulsifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also includes a preparation method of a low saturated water-in-oil margarine product, the specific steps are as follows:

[0066] (1) Oil phase preparation: Stir and mix the liquid oil and SUS structural grease in a water bath at 50-70°C, then cool to 30-40°C;

[0067] (2) Preparation of the water phase: dissolving the oil body and the optional flavor regulator in water, stirring evenly; and

[0068] (3) Low temperature emulsification: mix the oil phase obtained in step (1) and the water phase obtained in step (2), and stir under low temperature conditions.

[0069] In the above preparation process, the oil and SUS structural grease are first stirred evenly in a hot water bath. The stirring here is simple manual stirring. The temperature of the water bath is 50-70°C, preferably 55-65°C, more preferably 60°C ℃.

[0070] During the preparation of the water phase, the oil body is added to the water without adding a flavor regulator, and the oil body...

Embodiment 1

[0078] Embodiment one: stability evaluation

[0079] The formula (by mass percentage) of embodiment 1-10 is referring to table 1, and concrete preparation process is as follows:

[0080] (1) Oil phase preparation: Stir and mix liquid vegetable oil and SUS-type structured fat in a water bath at 60°C, then cool to 30-40°C.

[0081] (2) Preparation of water phase: Dissolve water-soluble ingredients such as salts and acidity regulators in water, take fresh oil bodies out of refrigerated conditions at 4°C and add them to the aqueous solution, and stir evenly.

[0082] (3) Low-temperature emulsification process: All the above-mentioned oil phases were added into the water phase, and after simple stirring and mixing, they were stirred under low temperature conditions, and the uniform milky white viscous samples were refrigerated and stored at 4°C.

[0083] In the process of low-temperature emulsification, Examples 1-4 and Comparative Examples 1-5 used an ice-water bath at 0°C and me...

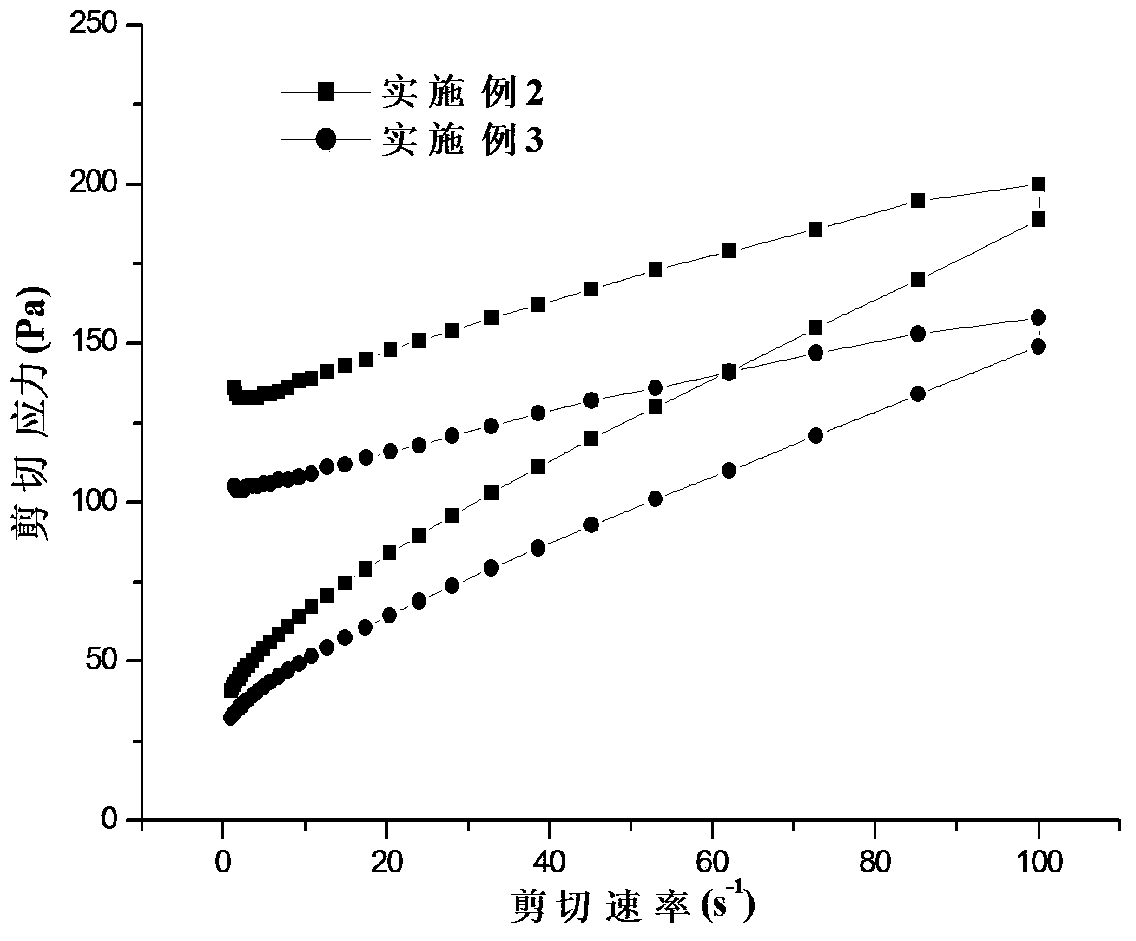

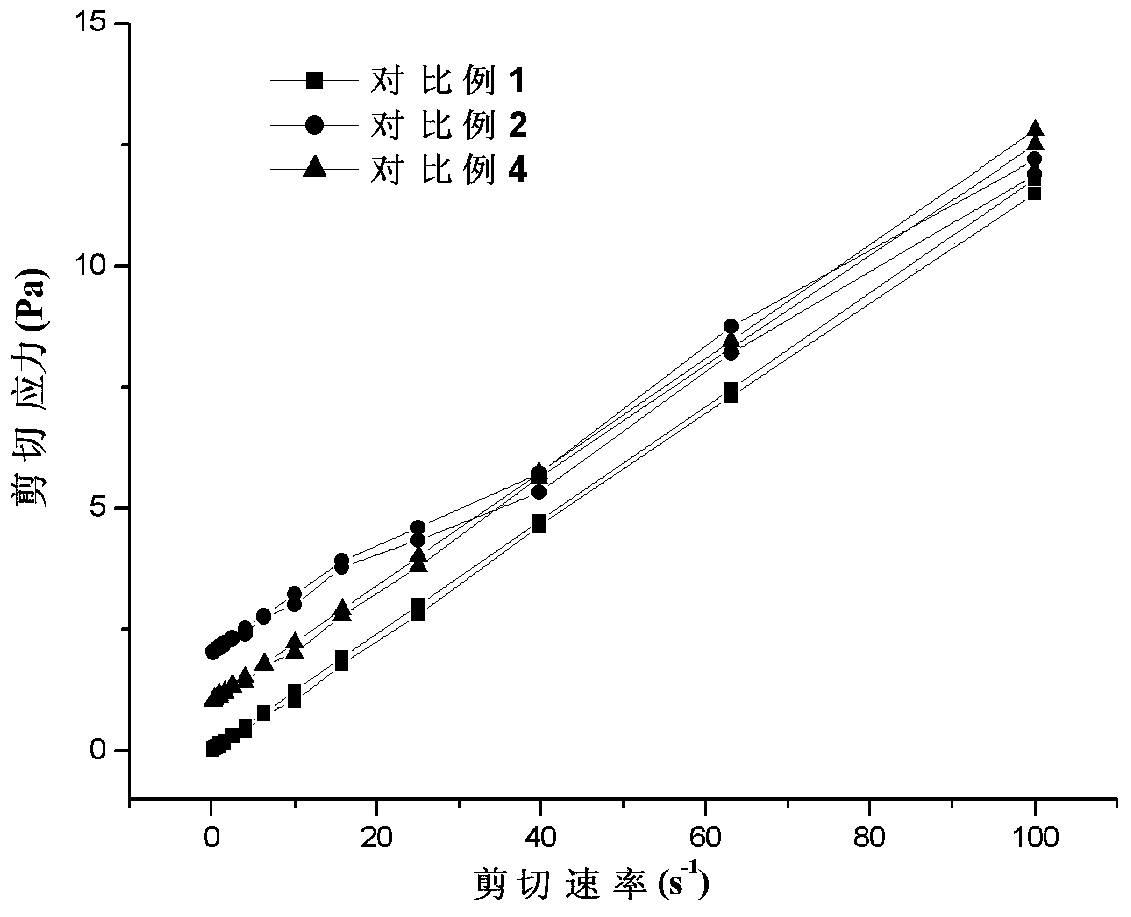

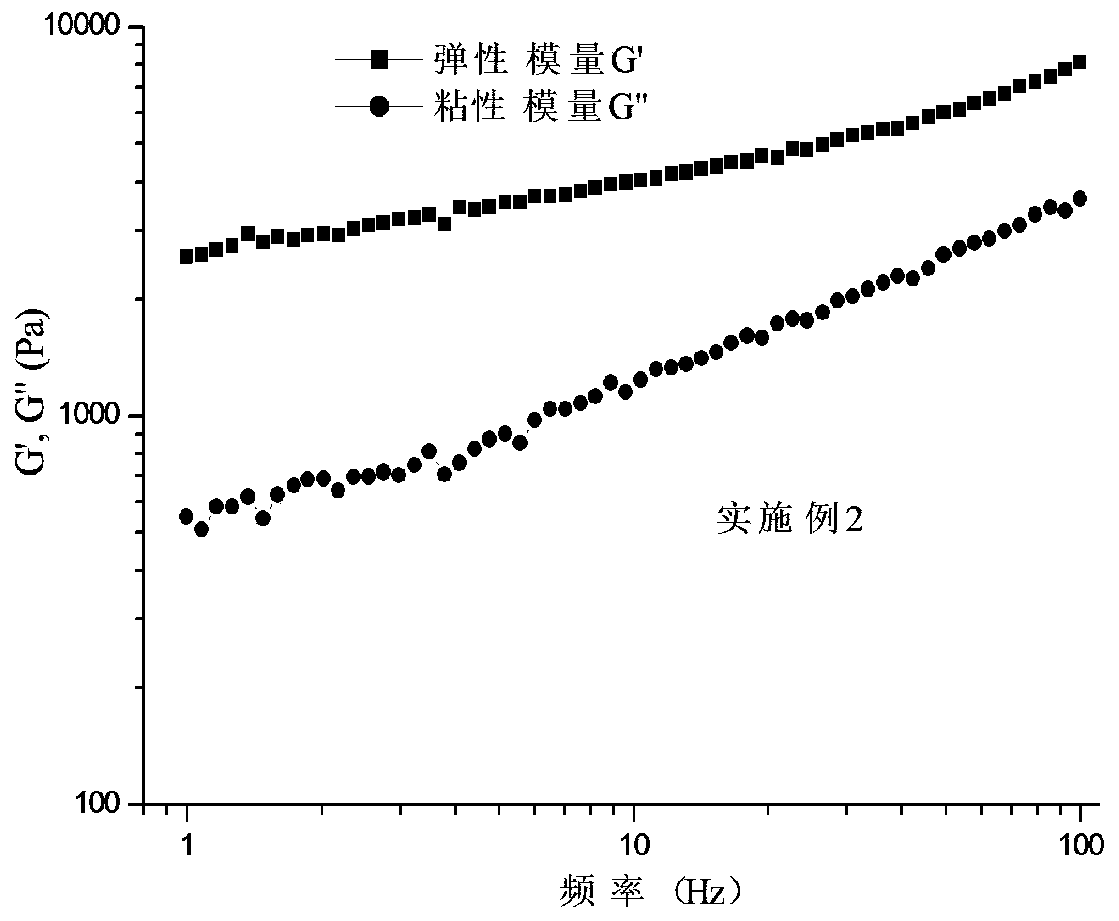

Embodiment 2

[0099] Example 2: Product cooking application experiment

[0100] For Examples 1-10 in Table 1, the inventors conducted simple cooking experiments and shallow frying experiments.

[0101] Splash property is an important evaluation index of cooking oil, and the evaluation of product splash behavior of the present invention is mainly divided into primary splash and secondary splash (with reference to CN 1390095 A-water-containing and oily emulsion), wherein,

[0102] Primary splash (SV1) is evaluated under standardized conditions (pan diameter 28cm, depth 4.5cm, circular paper disc diameter 40cm, distance 25cm from the bottom of the pan), cooking oil of the same quality is heated in a pan, and the moisture in the cooking oil After dissipating by heat, determine the amount of grease that is splashed and supported on a piece of paper above the pan.

[0103] Secondary splash (SV2) is also evaluated under standardized conditions (pot diameter 28cm, depth 4.5cm, circular paper diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com