Method and apparatus for profile and surface preparation of retaining rings for use in chemical mechanical polishing processes

A technology for retaining rings and outer rings, applied in the field of polishing systems, which can solve problems such as high capital and labor costs, and poor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

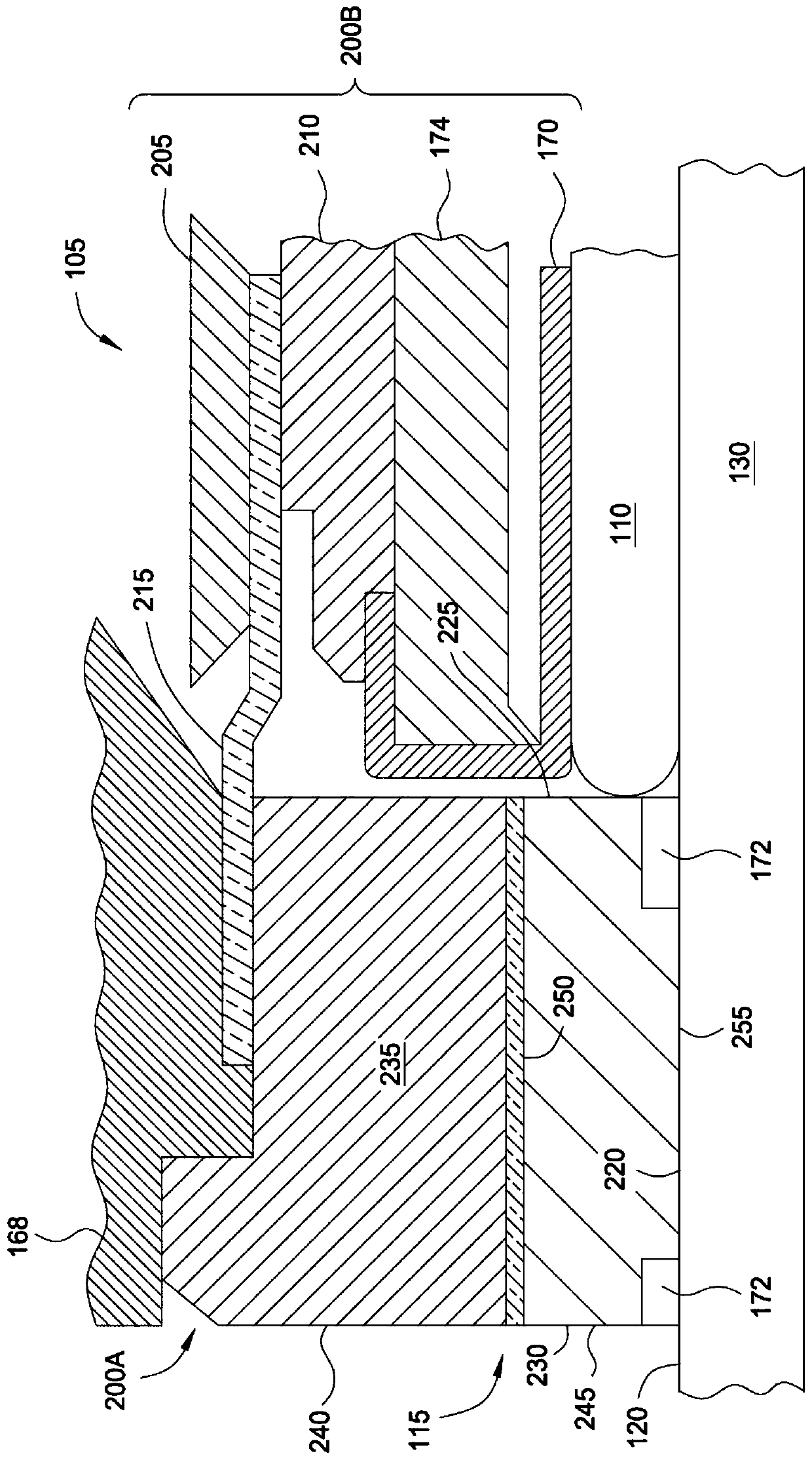

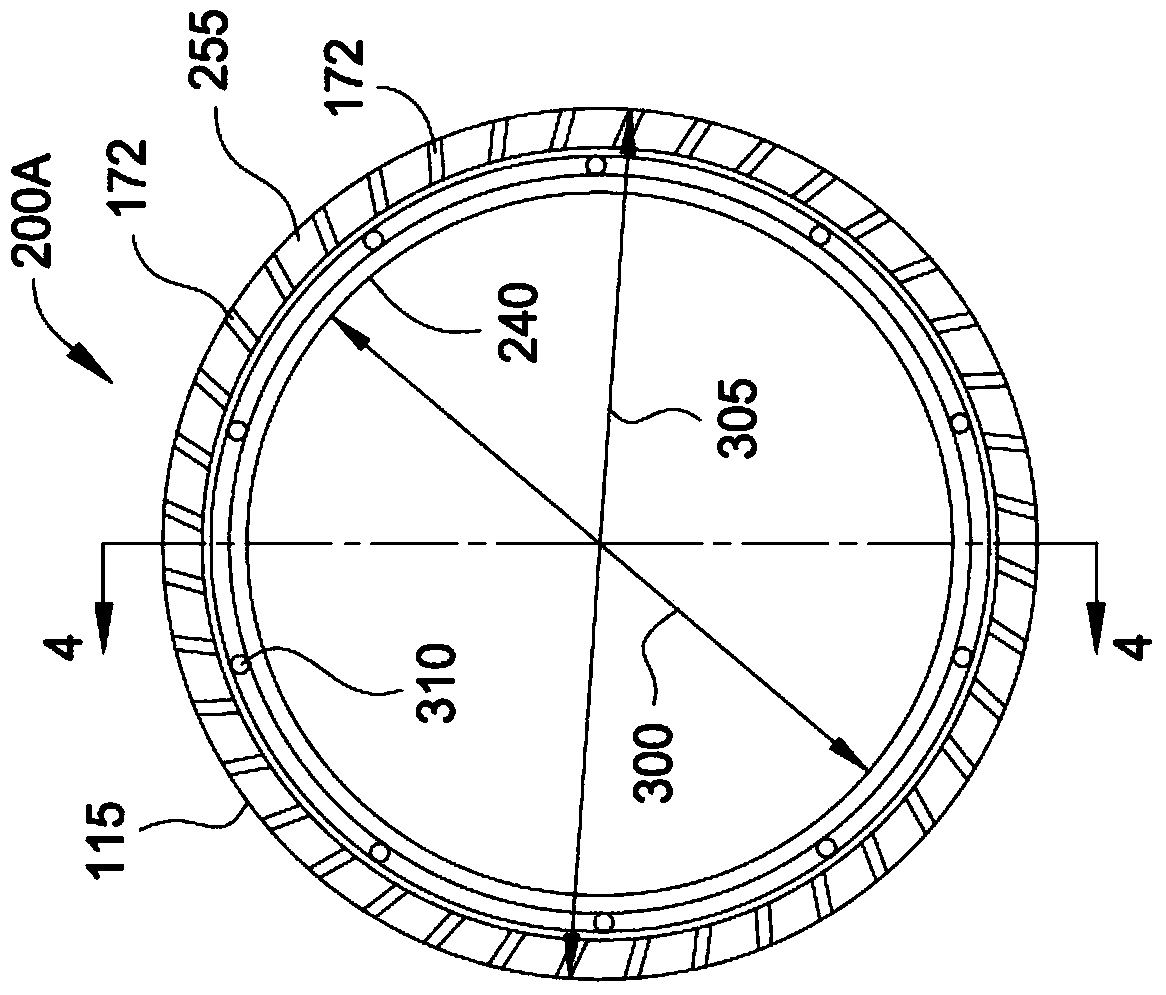

[0026] Retaining rings for polishing substrates, and methods for conditioning and / or refurbishing retaining rings are described herein. An apparatus for carrying out the method includes a fixture assembly coupled to a retaining ring to facilitate dressing and / or refurbishing.

[0027] figure 1 is a partial cross-sectional view of a chemical mechanical polishing (CMP) system 100 . The CMP system 100 includes a carrier head 105 that holds a substrate 110 (shown in phantom) in a retaining ring 115 and places the substrate 110 in contact with a polishing surface 120 of a polishing pad 125 during processing. The polishing pad 125 is disposed on the platen 130 . The platen 130 may be coupled to the motor 132 via a platen shaft 134 . Motor 132 rotates platen 130 , and thus polishing surface 120 of polishing pad 125 , about axis 136 of platen shaft 134 while CMP system 100 is polishing substrate 110 .

[0028] CMP system 100 may include chemical delivery system 138 and pad cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com