Inclined shaft open cutting lining section TBM main engine dropping method

A main engine and cut-and-cover technology, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the research and patent problems of the falling method of the TBM main engine in the lining section without open-cut, and achieve high structural safety and reliability. The effect of small construction risk and reduction of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

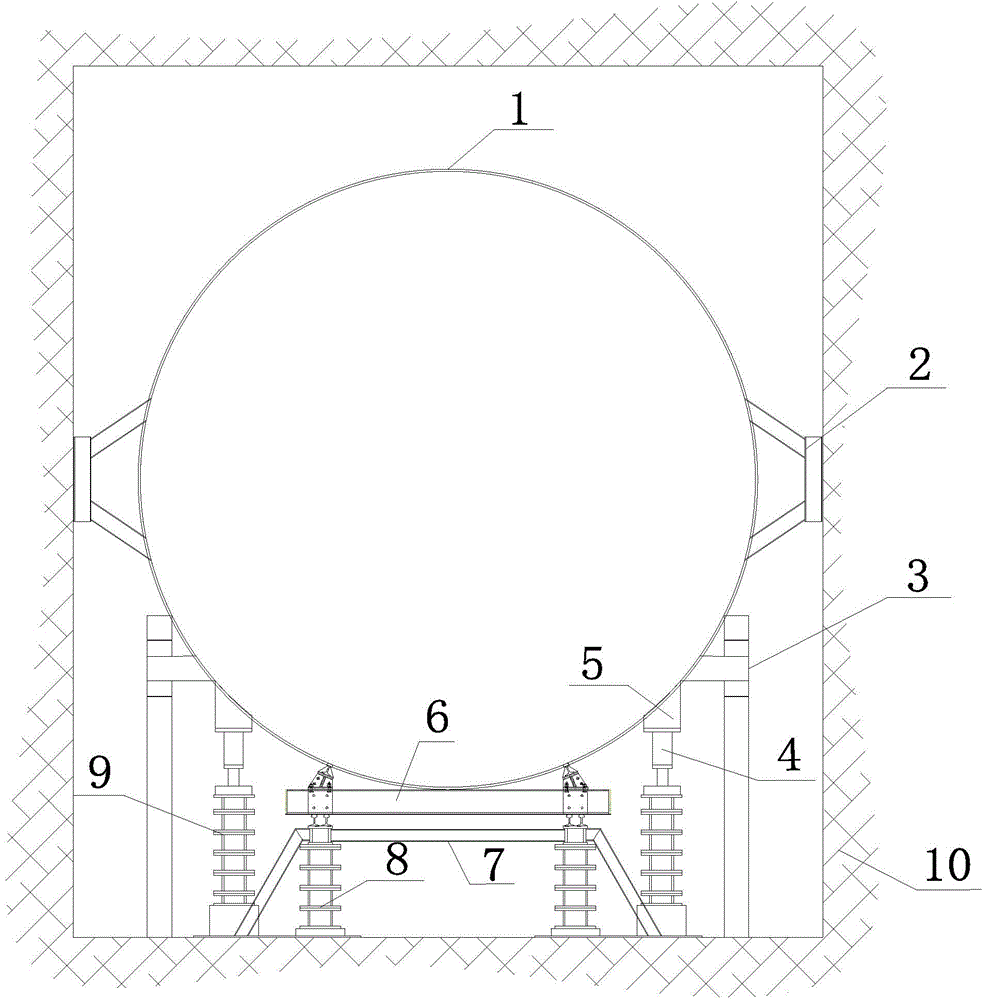

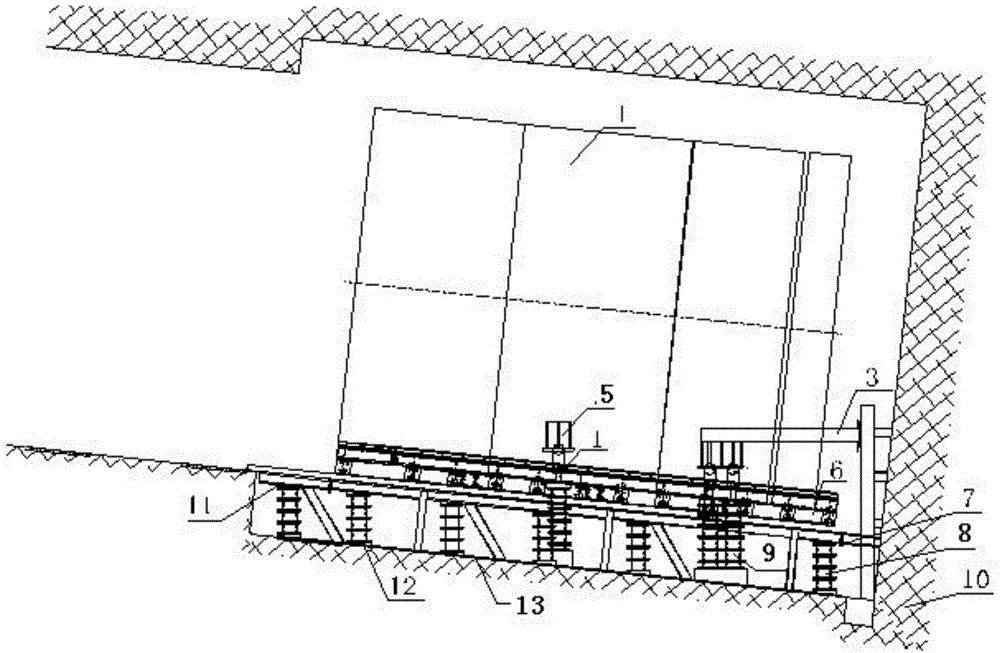

[0023] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0024] A method for dropping a main engine of a TBM in an open-cut lining section of an inclined shaft. The specific implementation process is as follows:

[0025] 1. Weld the anti-twist mechanism, oil cylinder support seat and anti-slip reaction force support frame on the host shield body, and apply butter on the surface of the anti-slide reaction force support mechanism;

[0026] 2. Place and weld support on the bottom steel plate of the TBM departure area. The falling system of the main engine (bottom inclined support block, upper circular support, box girder and top inclined support block), between the box girders and between the box girder and the bottom plate steel plate Install the support and weld the reaction device at the position of the door;

[0027] 3. Use the on-orbit heavy object pushing system to push the TBM host to the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com