A Method of Measuring the Runout of Steam Turbine Rotor

A steam turbine rotor and rotor technology, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems such as large errors and non-concentricity, and achieve the effects of satisfactory accuracy and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: a kind of method for measuring steam turbine rotor runout comprises the following steps:

[0019] Step 1: Clamp the rotor on the rotor lathe;

[0020] Step 2: Set the dial indicator on the section to be tested, and arrange a dial indicator on the journals at both ends of the rotor. The number of sections to be tested is n, 3≤n≤5;

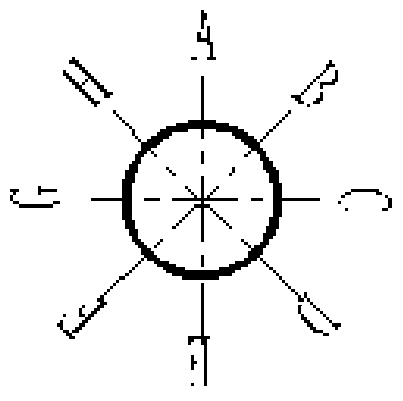

[0021] Step 3: Divide the rotor into 8 equal parts at the end of the rotor to obtain 8 phases, and mark them as A, B, C, D, E, F, G, H;

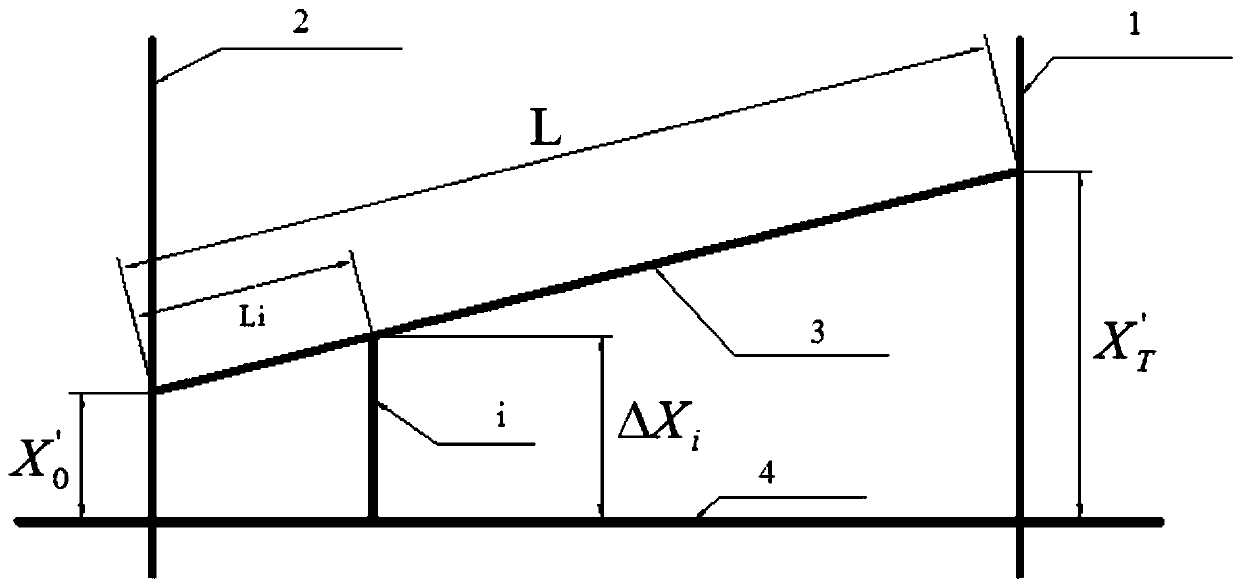

[0022] Step 4: The rotor car rotates at a constant speed of 2 revolutions per minute. When any one of A, B, C, D, E, F, G or H passes the dial indicator, read and record the reading of the dial indicator. Until all 8 phases are read and recorded; define the journal of the rotor adjustment end as 0, the journal of the electric end as T, set the measuring points in the order of 1, 2, 3,..., i from the adjustment end to the electric end, and define The A phase reading of the journal ...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: in the first step, the positioning reference for clamping the rotor on the rotor lathe is the journal, and the positioning accuracy is less than or equal to 0.05 mm.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dial indicator is fixed on the tool holder of the machine tool in the step 4, the tool holder is moved to the vicinity of the tested section, and the bracket is adjusted to make the dial indicator The sub-meter is in contact with the measured section of the rotor in the horizontal direction, and has a certain measured value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com