A tape initial tack tester

A technology of initial viscosity and testing machine, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of labor-consuming, time-consuming, many steps, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

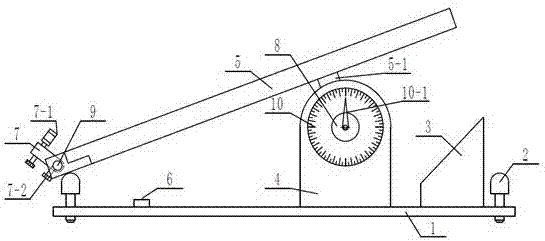

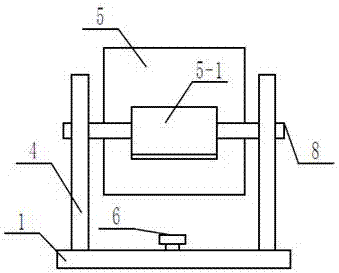

[0011] Depend on figure 1 , figure 2 Known, a kind of adhesive tape initial tack testing machine of the present invention, by bottom plate 1, support column 2, storage box 3, slant plate support plate 4, slant plate 5, level instrument 6, top block 7, slant plate central axis 8, top block The central axis 9 and the dial 10 are composed of the support column 2 set on the four corners of the base plate 1, the storage box 3 is fixed on the upper right side of the base plate 1, and the two sloping plates support 4 boards are symmetrically installed and fixed in the middle above the base plate 1 position, the central axis 8 of the inclined plate is fixed between the two support plates 4 of the inclined plate, the outrigger 5-1 of the inclined plate is set under the inclined plate 5 and passes through the central axis 8 of the inclined plate, and the spirit level 6 is fixed above the bottom plate 1 to the left position, the jacking block central axis 9 is installed on the tail of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com