Device and method for on-line rapid calibration of composite material pultruded profile

A technology of pultruded profiles and composite materials, which is applied in the field of on-line rapid calibration devices for composite pultruded profiles, which can solve problems such as cumbersome operation and failure to meet requirements, and achieve the effects of reducing wear, convenient regulation, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

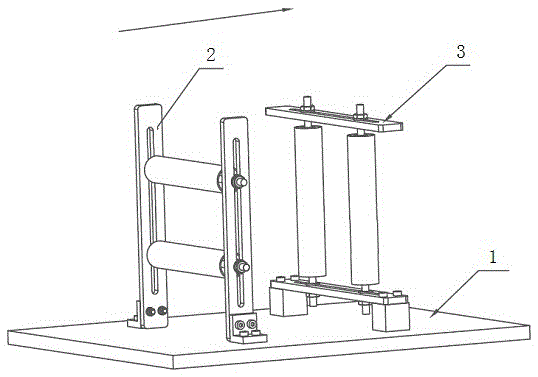

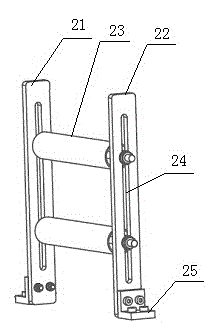

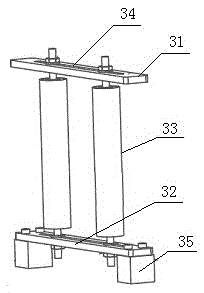

[0027] An online rapid calibration device for composite pultruded profiles, such as figure 1 , including a transverse limiting device 2 and a longitudinal limiting device 3, such as figure 2 , the lateral position-limiting device 2 comprises a left support plate 21, a right support plate 22 and more than two roller bodies 23 that are relatively parallel in the horizontal direction, and the left support plate 21 and the right support plate 22 are respectively provided with a longitudinal bar-shaped hole 24, and the roller body The two ends respectively pass through the strip holes and are fixed by nuts; image 3 , the longitudinal stop device 3 comprises an upper support plate 31, a lower support plate 32, and more than two roller bodies 33 arranged in parallel vertically, the upper support plate 31 and the lower support plate 32 are respectively provided with a transverse strip hole 34, and the roller body The two ends of two 33 respectively pass through the transverse strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com