Membrane rolling method capable of rolling two reverse osmosis membrane elements simultaneously

A technology of reverse osmosis membrane and membrane element, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as low efficiency of rolling membrane, and achieve the effect of improving efficiency, increasing production capacity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

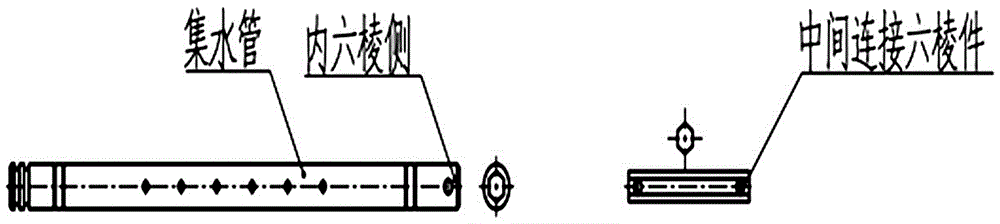

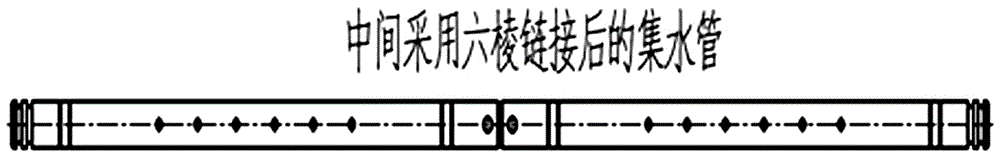

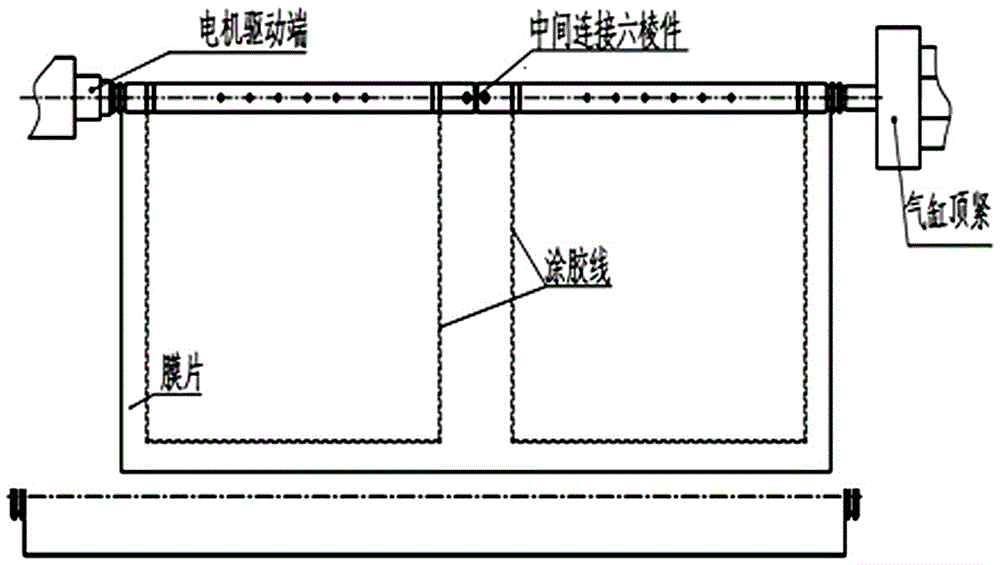

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples, but not as a limitation to the present invention.

[0035] For the convenience of explanation, we define the traditional one-time film rolling method as film rolling method 1, and the new method that can simultaneously roll two membrane elements as film rolling method 2.

[0036] Combined with the above analysis, taking rolling 1000 pieces of 2710-300 membrane elements as an example, it will be explained in detail how to roll two pieces of membrane elements at the same time at one time, and the comparison between this method and the film rolling method 1 in terms of efficiency and yield. The specific calculation methods include The following steps:

[0037] (1) First, determine the cutting size of the single 2710-300 membrane element diaphragm, the cutting size of the inlet flow channel cloth, the cutting size of the water flow channel cloth, and the number of sheets of membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com