Pipeline double-row deformation detection mechanism

A detection mechanism, double-row technology, applied in the direction of measuring devices, instruments, etc., to achieve the effect of avoiding missed detection, improving the ability to overcome obstacles, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

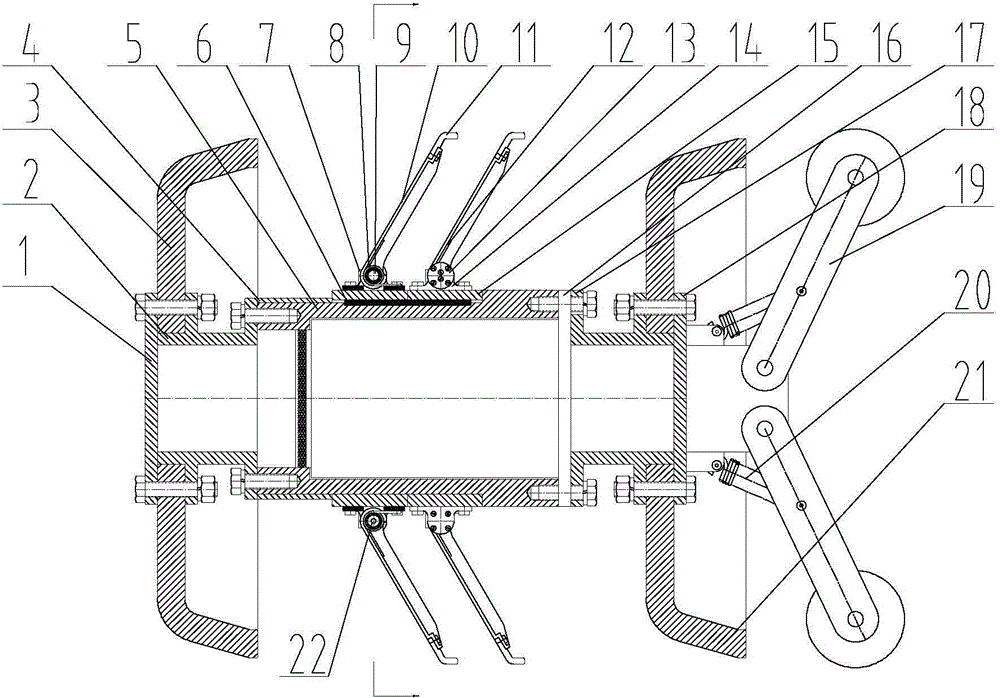

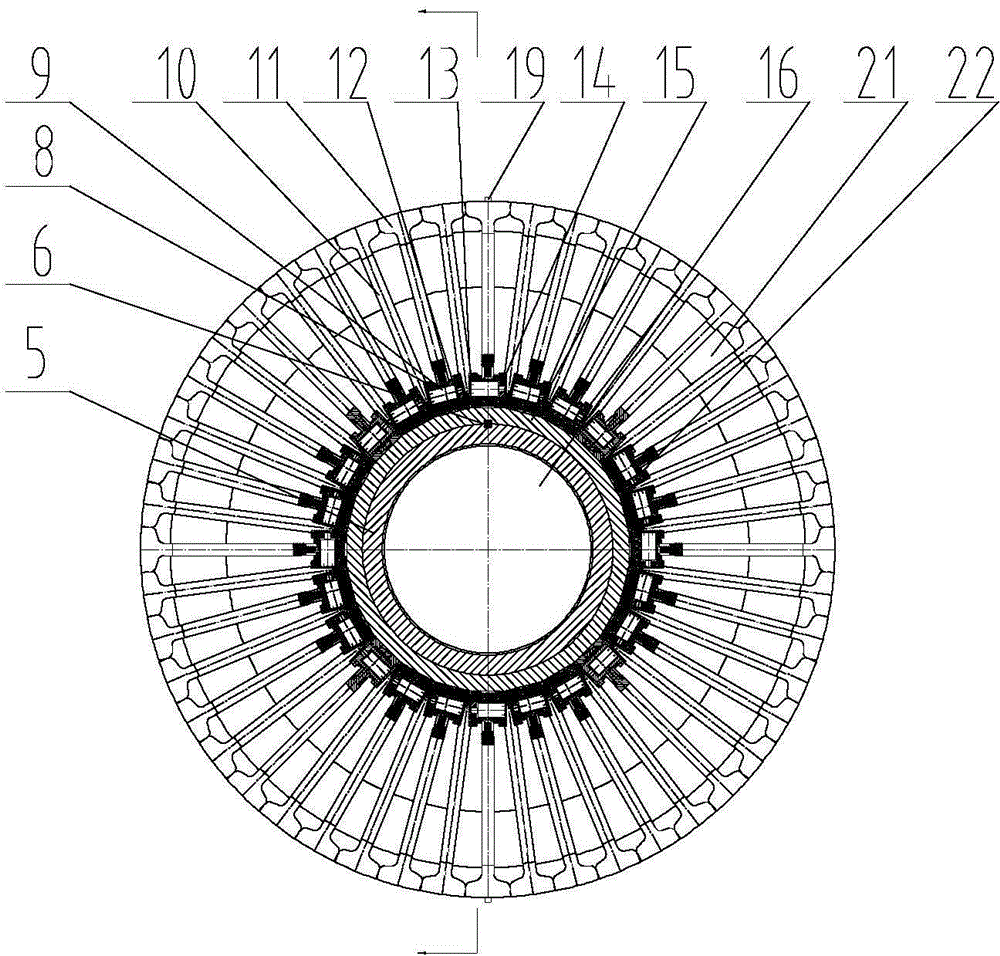

[0020] Attached to the manual figure 1 , 2 , Further describe the present invention:

[0021] Pipeline double -row deformed detection mechanism from front end cover 1. Ahead of the front holder 2, front leather bowl 3, fixed set 4, cylinder 5, positioning key 6, limit block 7, sales axis 8, angle displacement sensor 9, sensing arm arm 10. Sensor 11, twisted spring 12, end cover 13, supporting seat 14, sliding ring 15, sealing cabin 16, rear bracket 17, back end cover 18, mileage meter 19, pull spring 20, rear skin bowl 21, 21, rear skin bowl 21, 21, rear skin bowl 21, 21, 21, rear skin bowl 21, 21, 21, rear skin bowl 21, 21, 21, rear skin bowl 21, 21, 21, rear skin bowl 21, 21, 21, rear skin bowl 21. Sensing block 22 composition. The front end of the cylinder 5 is connected to the front bracket 2 through the screw connection, and the back end of the cylinder 5 is connected to the screw cabin 16 and the rear bracket 17, and the front leather bowl 3 is fixed on the front brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com