Compact multi-joint-section snake arm driving mechanism easy to expand

An easy-to-expand, multi-joint technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex connection between the drive rope 25 and the drive motor, the unfavorable increase in the overall movement of the robot, and the large space occupied by the drive motor. , to achieve the effect of compact drive structure, easy expansion and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] The compact and easily expandable multi-joint segment snake arm drive mechanism provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The same reference numerals are used for the same parts as in the prior art.

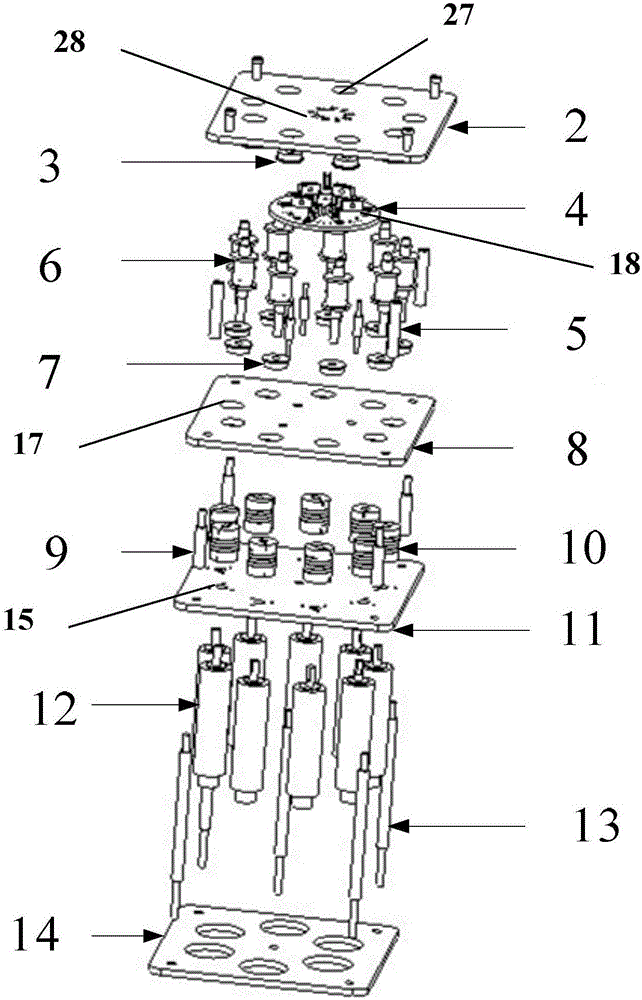

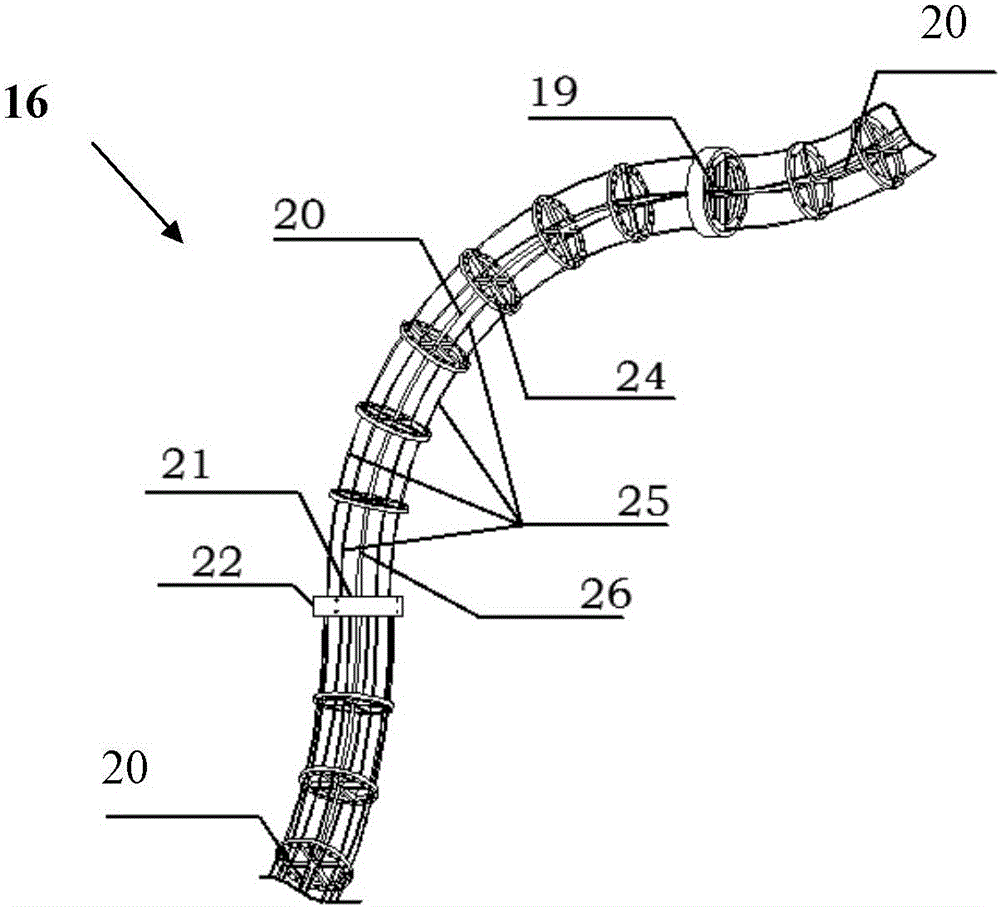

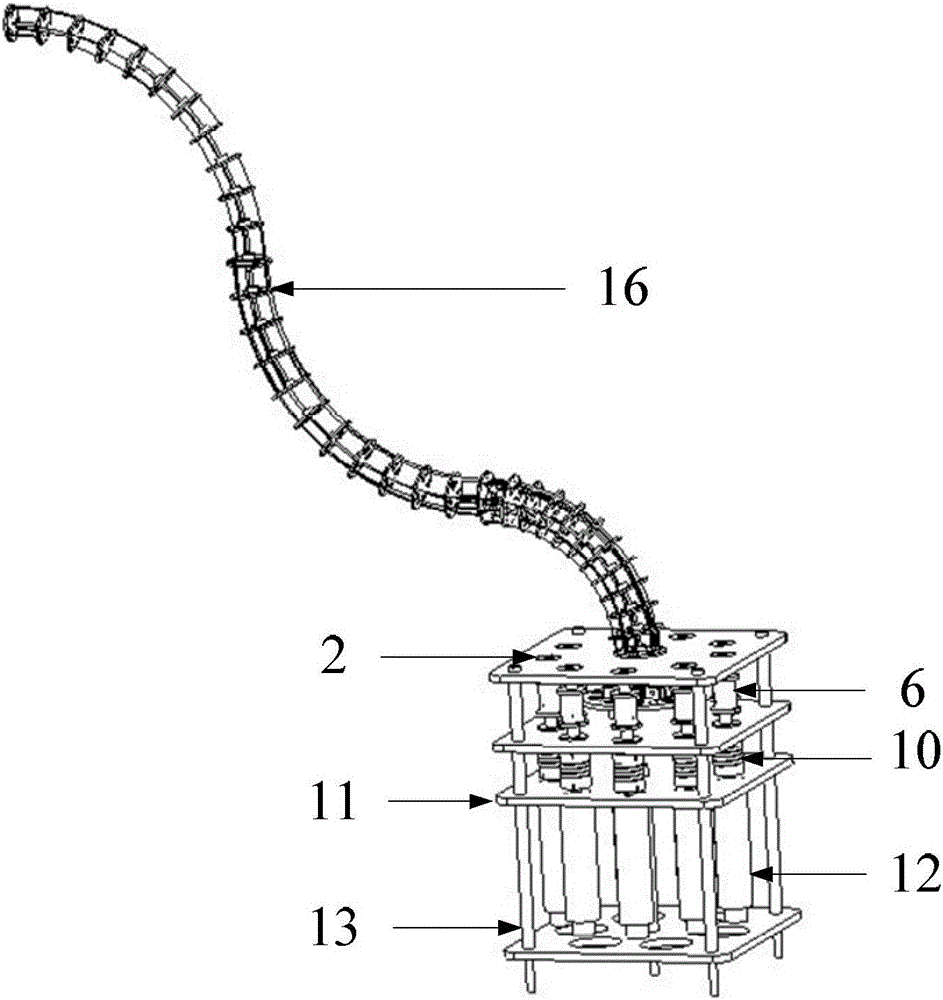

[0019] like figure 2 — Figure 5 As shown, the compact and easily expandable multi-joint segment snake arm drive mechanism provided by the present invention includes an upper bearing fixing plate 2, a plurality of upper flange bearings 3, a plurality of guide pulleys 4, a plurality of reels 6, and a plurality of lower flanges. Bearing 7, lower bearing fixing plate 8, a plurality of couplings 10, a motor fixing plate 11, a plurality of driving motors 12, a bottom plate 14 and a fixing plate 18; the output shaft of each driving motor 12 is arranged upward; the motor fixing plate 11 A plurality of bottom uprights 13 located at the edge and connected between the bottom plate 14 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap