In-ridge inter-plant wheel type weeding device

An inter-plant and wheel-type technology, applied in the field of agricultural machinery, can solve problems that have not been solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

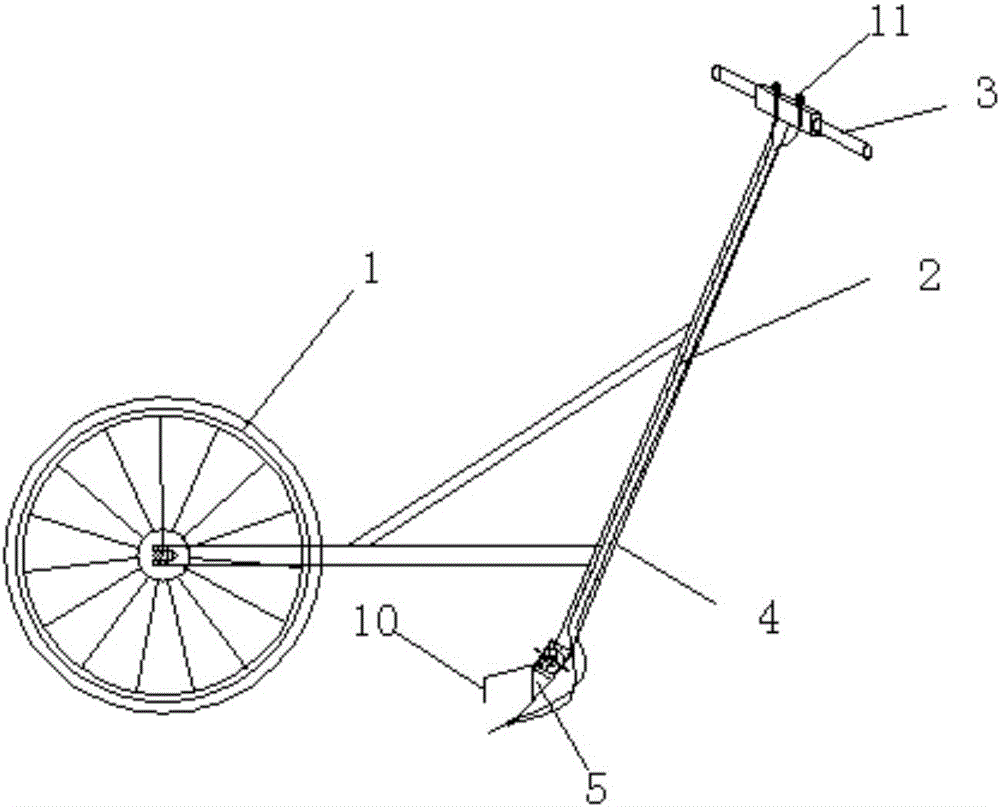

[0032] Such as figure 1 As shown, a wheel-type weeding device capable of performing inter-row weeding in a ridge of the present invention includes a front wheel 1, a frame 2, a handle 3, a knife rest 4, a spatula, and a connecting device 7 of the spatula. Only have a front wheel, be contained on the frame, handle is equipped with on the frame upper end, and the frame lower end is provided with the connection part knife rest 4 of blade. The connecting device of the blade is welded on the blade frame through the blade, and the connecting device is connected to the blade frame through connecting fastening bolts and nuts; when a person pushes the weeding device, the front wheel turns and walks, driving the blade Knife weeding work.

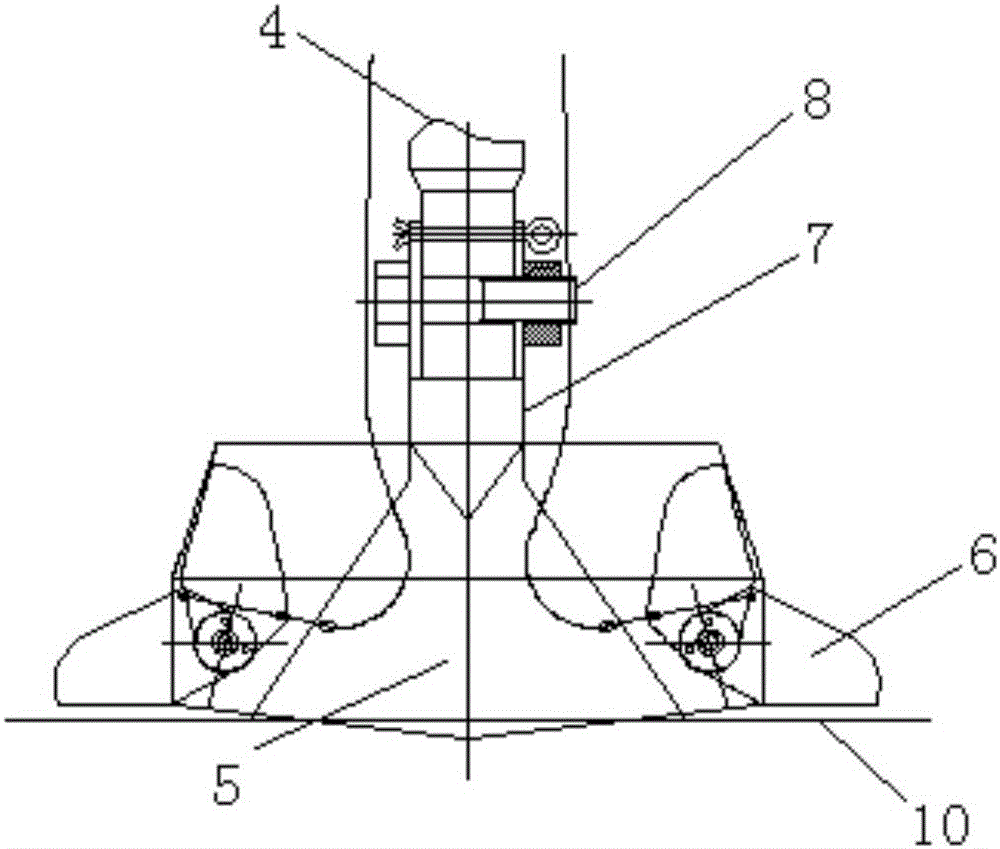

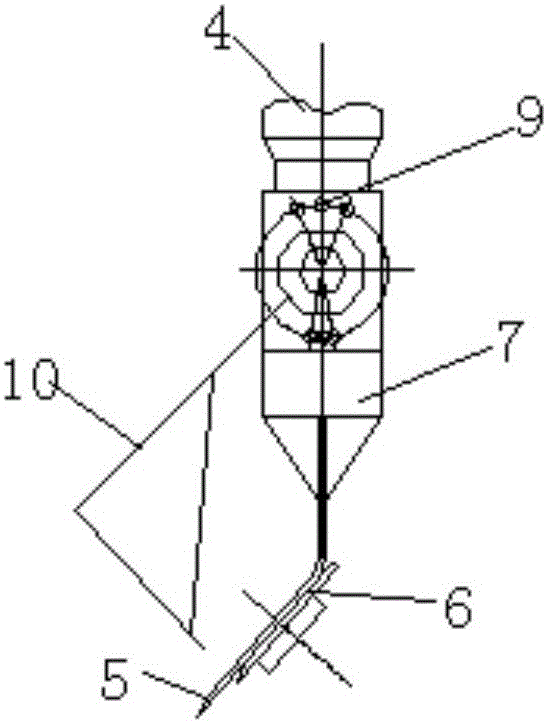

[0033] Such as figure 2 and image 3 As shown, the shovel is composed of a main shovel 5 and an auxiliary shov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap