A low-lead flame-retardant material for automotive bellows, its preparation method and application

A flame-retardant material and bellows technology, applied in the field of low-lead flame-retardant materials, can solve the problems that material manufacturers are difficult to achieve, and achieve the effects of excellent impact resistance, good flame retardancy, low temperature and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

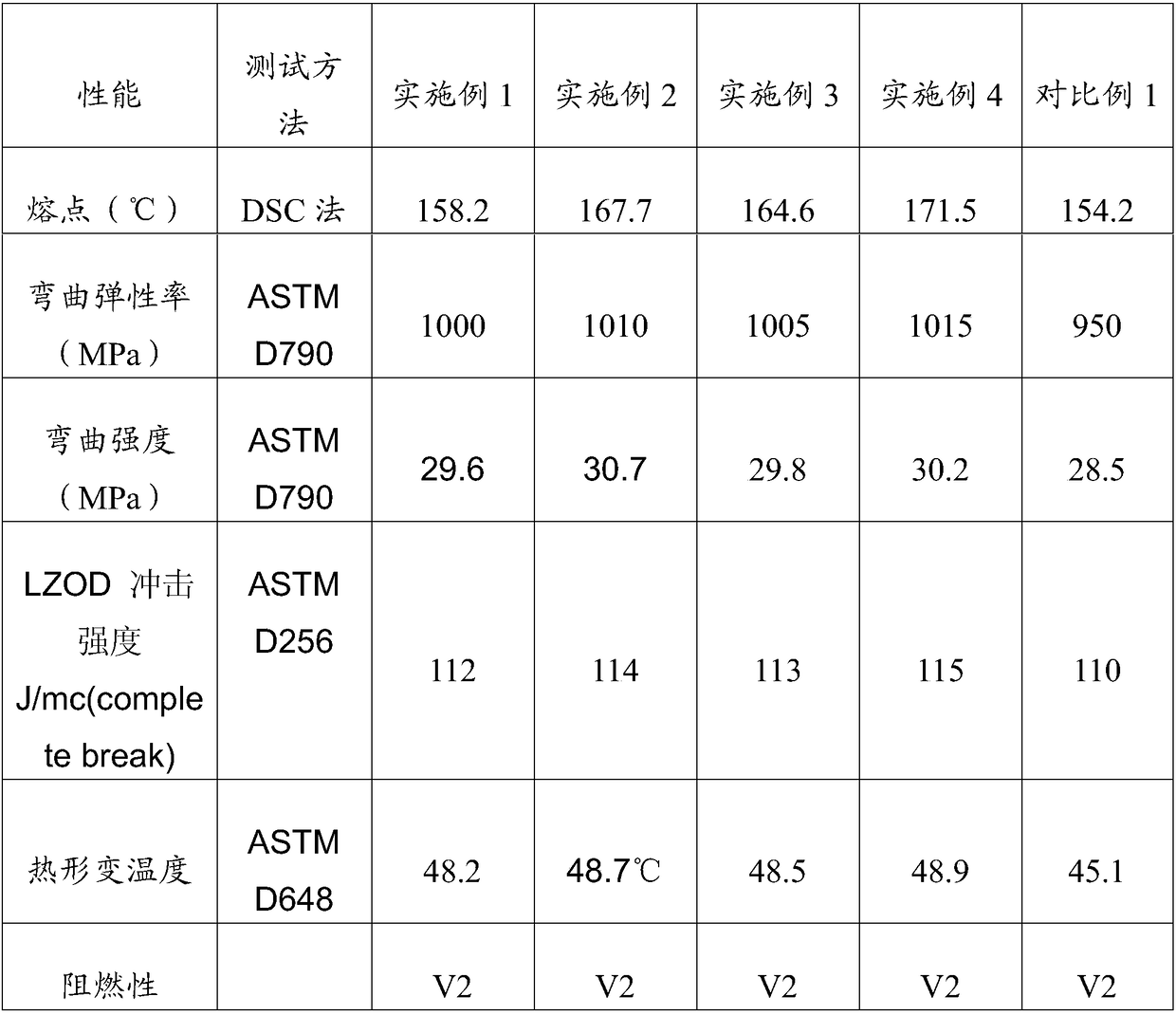

Examples

Embodiment 1

[0031] A low-lead flame-retardant material for automotive bellows, comprising the following raw materials in parts by weight: 70 parts of polypropylene, 30 parts of talcum powder, 2 parts of black masterbatch, 1.5 parts of coupling agent, 5 parts of compatibilizer, retardant 18 parts of fuel, 3 parts of impact modifier, 3 parts of organoclay nano-reinforced elastomer composite material, 2 parts of lubricant and 2 parts of antioxidant;

[0032] Described coupling agent is the mixture of epoxy resin and vinyltriethoxysilane, wherein, the mass ratio of epoxy resin and vinyltriethoxysilane is 1:4;

[0033] The compatibilizer is a mixture of maleic anhydride grafted PP, maleic anhydride grafted PE and polypropylene grafted glycidyl acrylate, wherein maleic anhydride grafted PP, maleic anhydride grafted PE and polypropylene grafted The mass ratio of glycidyl acrylate is 5:2:3;

[0034] The flame retardant is composed of tri-(tribromophenoxy)-triazine and an auxiliary flame retardan...

Embodiment 2

[0042] A low-lead flame-retardant material for automotive bellows, comprising the following raw materials in parts by weight: 90 parts of polypropylene, 40 parts of talcum powder, 4 parts of black masterbatch, 1 part of coupling agent, 6 parts of compatibilizer, retardant 15 parts of fuel, 4 parts of impact modifier, 4 parts of organoclay nano-reinforced elastomer composite material, 1 part of lubricant and 1 part of antioxidant;

[0043] Described coupling agent is the mixture of epoxy resin and vinyltriethoxysilane, wherein, the mass ratio of epoxy resin and vinyltriethoxysilane is 1:5;

[0044] The compatibilizer is a mixture of maleic anhydride grafted PP, maleic anhydride grafted PE and polypropylene grafted glycidyl acrylate, wherein maleic anhydride grafted PP, maleic anhydride grafted PE and polypropylene grafted The mass ratio of glycidyl acrylate is 6:2.5:4;

[0045]The flame retardant is composed of tri-(tribromophenoxy)-triazine and an auxiliary flame retardant in...

Embodiment 3

[0051] A low-lead flame-retardant material for automotive bellows, comprising the following raw materials in parts by weight: 100 parts of polypropylene, 50 parts of talcum powder, 5 parts of black masterbatch, 2 parts of coupling agent, 8 parts of compatibilizer, retardant 30 parts of fuel, 5 parts of impact modifier, 5 parts of organoclay nano-reinforced elastomer composite material, 3 parts of lubricant and 3 parts of antioxidant;

[0052] Described coupling agent is the mixture of epoxy resin and vinyltriethoxysilane, wherein, the mass ratio of epoxy resin and vinyltriethoxysilane is 1:3;

[0053] The compatibilizer is a mixture of maleic anhydride grafted PP, maleic anhydride grafted PE and polypropylene grafted glycidyl acrylate, wherein maleic anhydride grafted PP, maleic anhydride grafted PE and polypropylene grafted The mass ratio of glycidyl acrylate is 7:3:5;

[0054] The flame retardant is composed of tri-(tribromophenoxy)-triazine and an auxiliary flame retardant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com