An automatic arranging machine for radiating strip ceramic sheets

A technology of ceramic sheets and cooling strips, which is applied in the field of automatic arrangement of ceramic sheets for cooling strips, can solve the problems of slow production speed, time-consuming and laborious, etc., and achieve the effect of high degree of automation and compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

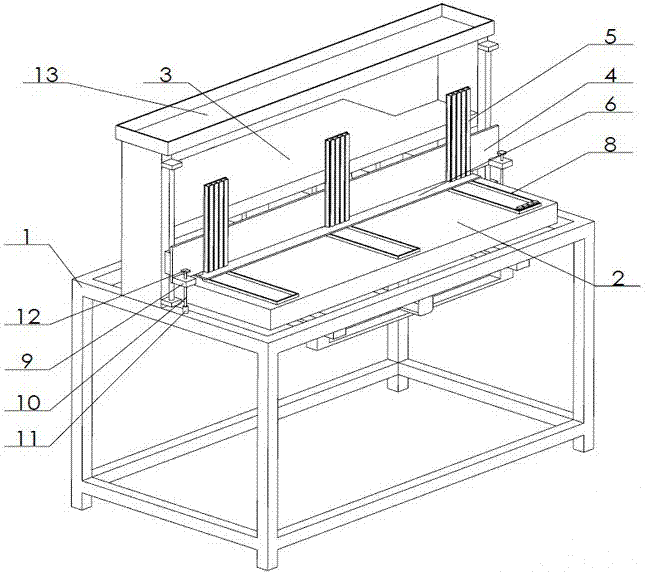

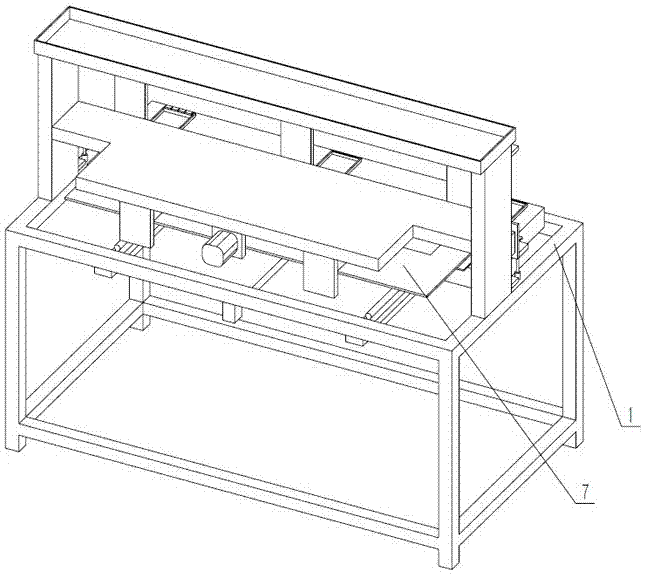

[0016] like Figure 1-2 As shown, the automatic arranging machine for radiating strip ceramic sheets includes a frame body 1, on which a workbench 2 reciprocatingly moves along the short side direction of the frame body 1, and a beam 3 is fixed above the frame body 1 , the first mounting plate 4 connected to one side of the crossbeam 3 can be lifted up and down, and a plurality of ceramic chip placement grooves 5 fixed on the first mounting plate 4, a partition plate 6 is fixed between the placement groove 5 and the workbench 2, A push plate 7 that moves along the short side of the frame body 1 is provided between the partition plate 6 and the placement slot 5 .

[0017] Specifically, the placing groove 5 is formed with a plurality of vertical rectangular through grooves, and the distance between the bottom of the placing groove 5 and the partition plate 6 is the thickness of a ceramic sheet.

[0018] Specifically, the bottom of the workbench 2 is connected to the frame body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com