A glass fiber reinforced pert pipe is a prefabricated direct-buried thermal insulation plastic pipe and its preparation method

A glass fiber, prefabricated direct burial technology, applied in pipeline protection, pipe/pipe joints/pipe fittings, thermal insulation, etc., can solve the problems of restricting the popularization and application of prefabricated direct burial thermal insulation plastic pipes, reduce the thermal expansion coefficient, avoid cost, design The effect of stress increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

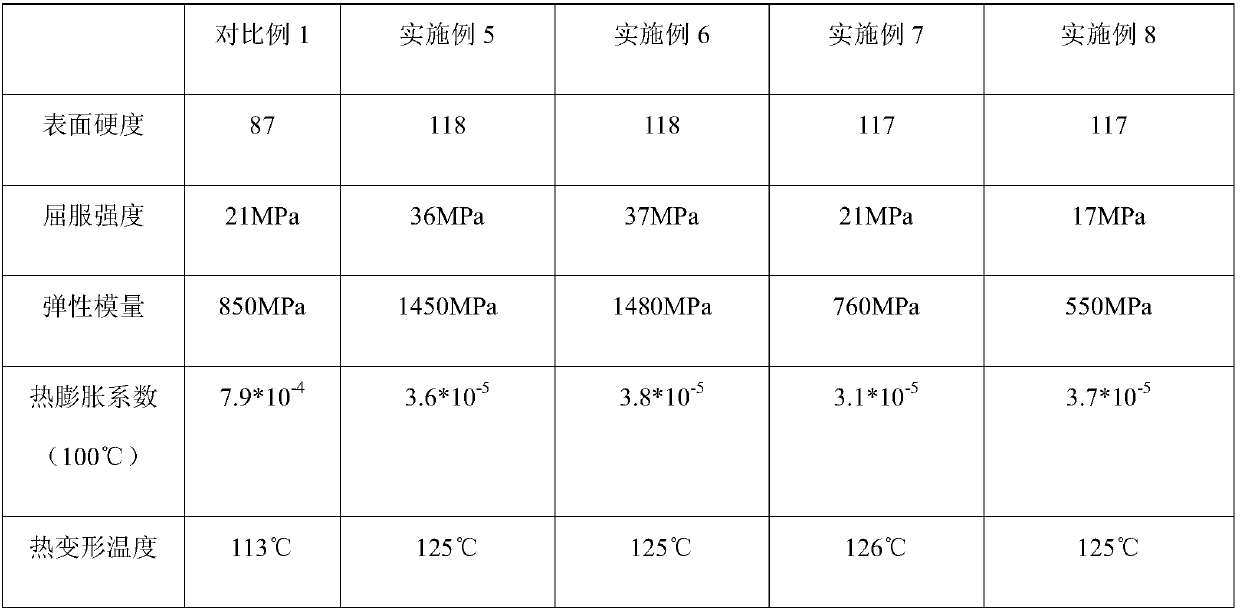

Embodiment 1

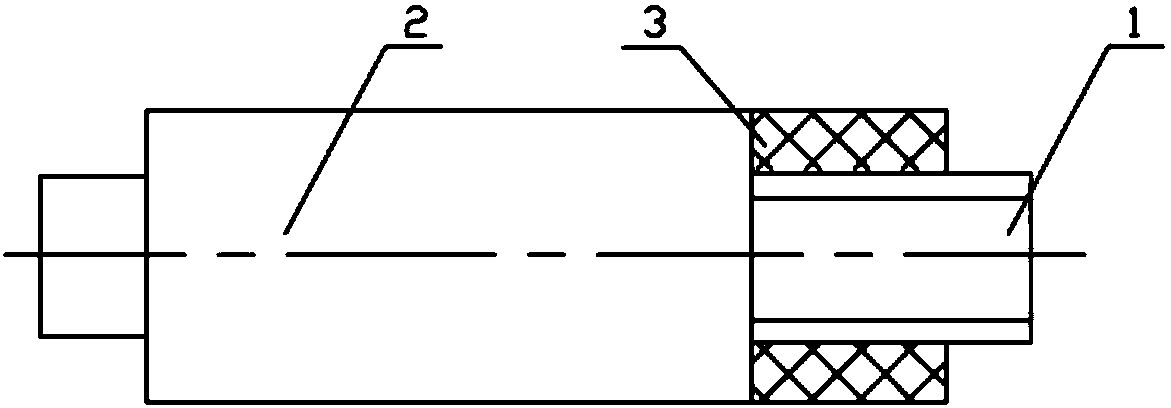

[0026] Depend on figure 1 Shown: A glass fiber reinforced PERT pipe is a prefabricated direct-buried thermal insulation plastic pipe with a working tube, including a working inner tube and an outer sheath tube, the working inner tube and the outer sheathing tube are connected by an insulation layer, and the working inner tube is made of glass fiber The reinforced PERT pipe 1, the outer sheath pipe is an HDPE pipe 2, and the insulation layer is a rigid polyurethane foam insulation layer 3.

[0027] The glass fiber reinforced PERT pipeline is a preparation method for a prefabricated directly buried thermal insulation plastic pipeline of a working pipe, comprising the following steps:

[0028] (1) Preparation of glass fiber-reinforced PERT pipes: Burn the glass fiber to 400°C to treat the surface oil, chop it to a length of 10 mm, and soak it in an ethanol solution containing 1% by mass of silane coupling agent 171. The fiber and PERT are mixed in a ratio of 1:4 by mass, and ext...

Embodiment 2

[0032] Same as Example 1, the difference is:

[0033] The mass ratio of glass fiber to PERT is 3:7.

Embodiment 3

[0035] Same as Example 1, the difference is:

[0036] The mass ratio of glass fiber to PERT is 1:9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com