A kind of preparation method of protein-based surfactant

A surfactant and protein-based technology is applied in the field of preparation of surfactants to achieve the effects of easy biodegradation, strong biodegradability and good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

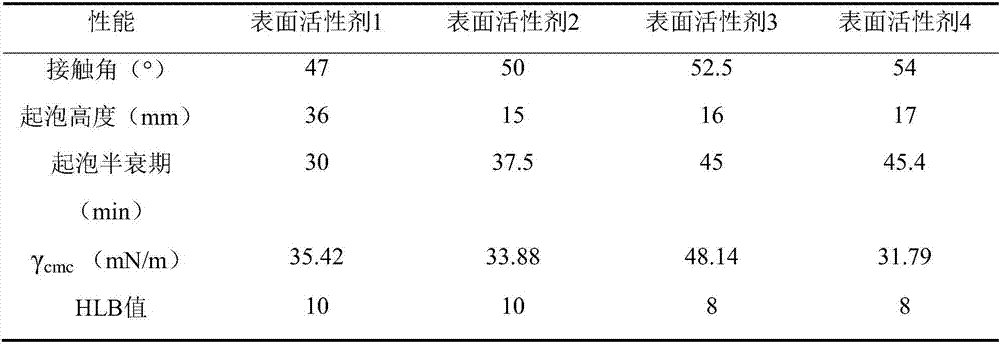

Image

Examples

Embodiment 1

[0023] (1) Preparation of compound polypeptide hydrolyzate: Dry 30g of blue leather scraps from the tannery in an oven to constant weight and crush them into leather scraps, take 20g of dried leather scraps and place them in a tank equipped with a condenser tube, thermometer and agitator In a three-necked flask, 2g of tetramethylammonium hydroxide was dissolved to a concentration of 5g / L, and added to the three-necked flask. Control the temperature of the water bath in the three-necked flask to 80°C, and the hydrolysis time is 8 hours. Hydrolyze the chromium-containing leather scraps. After the hydrolysis, filter, transfer to an oven, bake at 130°C until 0.5h to decompose excess tetramethylammonium hydroxide, and distill under reduced pressure Concentrate the hydrolyzate to a concentration of 0.2g / ml, and store it in the refrigerator at 0-4°C for later use; the viscosity-average molecular weight of the hydrolyzed compound polypeptide hydrolyzate is M η =40000~50000.

[0024] ...

Embodiment 2

[0027] (1) Preparation of compound polypeptide hydrolyzate: 30g of blue leather scraps (leather shavings) from the tannery are dried to constant weight in an oven and pulverized into leather shavings; In a three-necked flask with a thermometer and a stirrer, dissolve 1.8 g of tetramethylammonium hydroxide to a concentration of 6 g / L, and add it into the three-necked flask. Control the temperature of the water bath in the three-necked flask to 85°C, and the hydrolysis time is 9 hours to hydrolyze the leather shavings containing chromium. After the hydrolysis is completed, filter, transfer to an oven, bake at 140°C for 0.5h to decompose excess tetramethylammonium hydroxide, and distill under reduced pressure The concentration of the concentrated hydrolyzate is 0.3g / ml, and it is stored in the refrigerator at 0-4°C for later use;

[0028] (2) Preparation of phase transfer catalyst: Take 15g of the above-mentioned concentrated hydrolyzate and place it in a three-necked flask, and ...

Embodiment 3

[0031] (1) Preparation of compound polypeptide hydrolyzate: 30g of blue leather scraps (leather shavings) from the tannery are dried to constant weight in an oven and pulverized into leather shavings; In a three-necked flask with a thermometer and a stirrer, dissolve 2 g of tetramethylammonium hydroxide to a concentration of 5 g / L, and add it into the three-necked flask. Control the temperature of the water bath in the three-necked flask to 90°C, and the hydrolysis time is 10 hours to hydrolyze the leather shavings containing chromium. After the hydrolysis, filter, transfer to an oven, bake at 145°C for 0.5h to decompose excess tetramethylammonium hydroxide, and distill under reduced pressure Concentrate the hydrolyzate to a Baume degree of 0.4g / ml, and store it in the refrigerator at 0-4°C for later use;

[0032](2) Preparation of phase transfer catalyst: take 20 g of the above-mentioned concentrated hydrolyzate and place it in a three-necked flask, and dissolve 4 g of 2,3-ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com