Method for simulating pyridine in gasoline through pervaporation membrane separation

A pervaporation membrane and pervaporation technology, which is applied in the field of pervaporation membrane separation, can solve the problems of high investment cost, high energy consumption, and environmental pollution, and achieve the effects of guaranteed yield, low energy consumption, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

[0030] Method for separating pyridine in simulated gasoline by pervaporation membrane

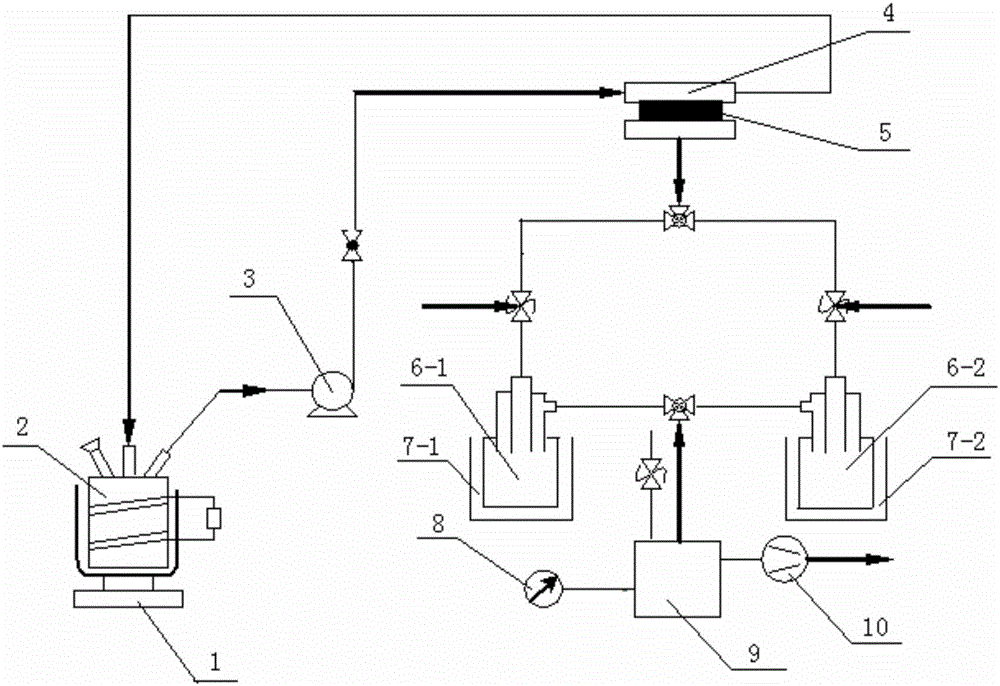

[0031] Set the pyridine concentration to 500μg·g -1 The nitrogen-containing simulated gasoline is placed in the feed liquid tank 2, and is preheated by the feed liquid preheating device 1. The preheating temperature is 30°C, and the pyridine concentration is 500 μg·g -1 The nitrogen-containing simulated gasoline is transported from the feed liquid tank 2 to the pervaporation membrane separator 4 by the feed liquid circulation pump 3, and is selectively permeated through the pervaporation separation membrane 5. The permeated gas enters the permeate tank 6, and is condensed by the sample condensation system 7. After analysis, the non-permeated liquid is circulated back into the liquid tank through the liquid circulation pump 3, and the permeate side of the pervaporation membrane separator is kept at a low pressure by the vacuum pump 10. The permeate side of the pervaporation mem...

Example Embodiment

[0032] Example 2

[0033] Method for separating pyridine in simulated gasoline by pervaporation membrane

[0034] Set the pyridine concentration to 2000μg·g -1 The nitrogen-containing simulated gasoline is placed in the feed liquid tank 2, and is preheated by the feed liquid preheating device 1. The preheating temperature is 30℃, and the pyridine concentration is 2000μg·g -1 The nitrogen-containing simulated gasoline is transported from the feed liquid tank 2 by the feed liquid circulation pump 3 to the pervaporation membrane separator 4, and is selectively permeated through the pervaporation separation membrane 5. The permeate gas enters the permeate tank 6, and is condensed by the sample condensation system 7. After analysis, the non-permeated liquid is circulated back into the material liquid tank through the material liquid circulation pump 3, and the permeate side of the pervaporation membrane separator is kept at a low pressure by the vacuum pump 10. The permeate side of the ...

Example Embodiment

[0035] Example 3

[0036] Method for separating pyridine in simulated gasoline by pervaporation membrane

[0037] Set the pyridine concentration to 5000μg·g -1 The nitrogen-containing simulated gasoline is placed in the feed liquid tank 2, and is preheated by the feed liquid preheating device 1. The preheating temperature is 30℃, and the pyridine concentration is 5000μg·g -1 The nitrogen-containing simulated gasoline is transported from the feed liquid tank 2 by the feed liquid circulation pump 3 to the pervaporation membrane separator 4, and is selectively permeated through the pervaporation separation membrane 5. The permeate gas enters the permeate tank 6, and is condensed by the sample condensation system 7. After analysis, the non-permeated liquid is circulated back into the material liquid tank through the material liquid circulation pump 3, and the permeate side of the pervaporation membrane separator is kept at a low pressure by the vacuum pump 10. The permeate side of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total permeate flux | aaaaa | aaaaa |

| Total permeate flux | aaaaa | aaaaa |

| Total permeate flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap