A method and auxiliary device for manufacturing a heat exchange tube exposed heat exchanger

A technology of auxiliary devices and heat exchange tubes, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as large flexibility, heat exchange tube damage, and long tube bundle length, so as to facilitate mass production and improve the degree of automation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0082] According to a preferred embodiment of the present invention, the preparation method also includes:

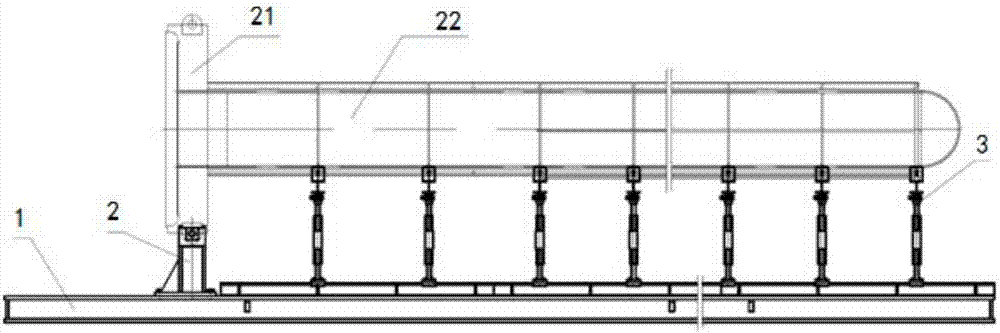

[0083] Step 5): insert the tube bundle assembly 22 after the tube is inserted into the temporary housing device, optionally disassemble the tube sheet support 2 after inserting, and seal and weld the outer edge of the tube sheet 21 with the temporary housing 4, and then optionally Relying on the support 8 to place to the station; and

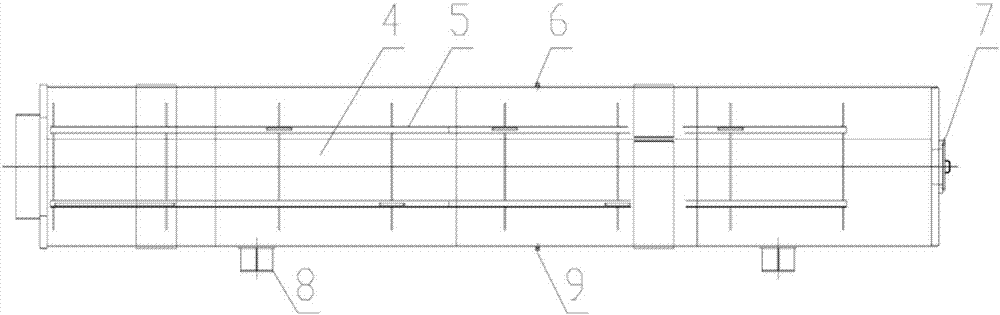

[0084] Step 6): Sealing the manhole 7 and the air outlet 9, feeding compressed air through the air inlet 6, and checking the airtightness of the weld between the heat exchange tube (or heat exchange tube bundle) and the tube sheet 21 .

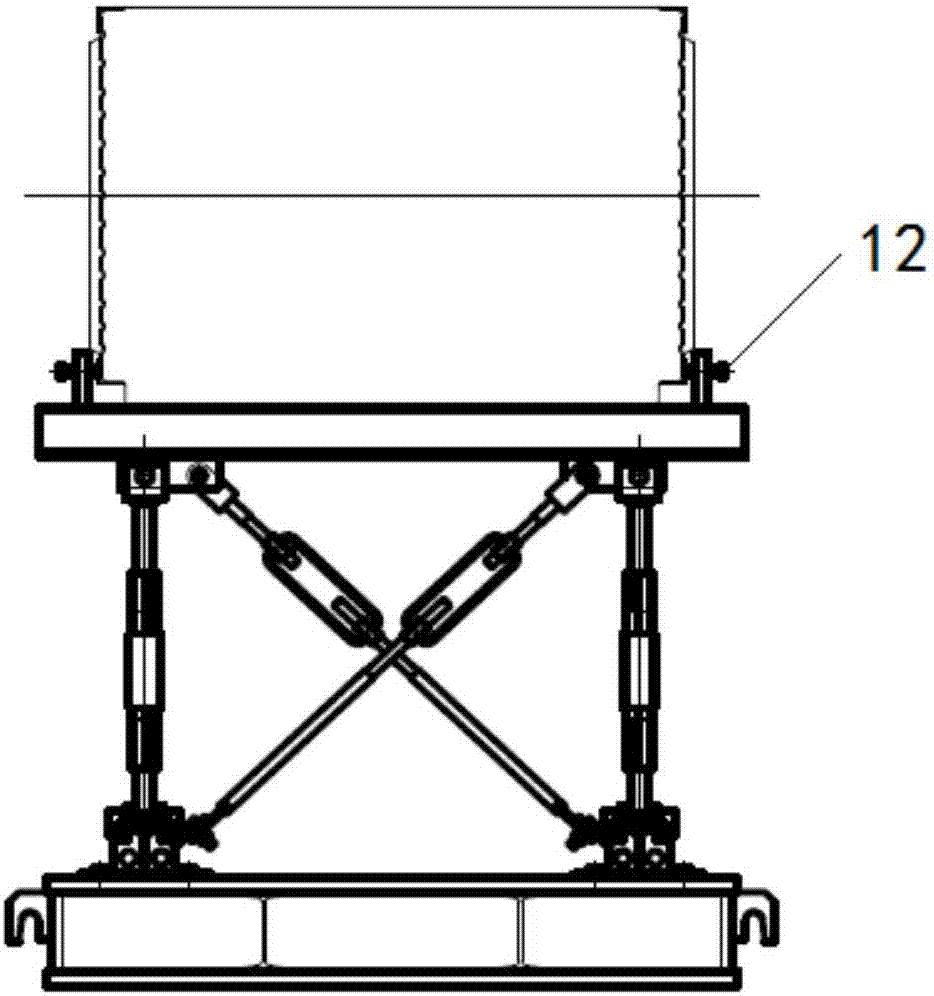

[0085] In step 5, the tube bundle assembly after the pipe is inserted into the temporary cylinder 4, the tube bundle assembly slides into the temporary cylinder 4 along the internal support rail 5, and the connecting rod assembly 3 is disassembled at the same time, preferably, during the insertion process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com