Vacuum fast slag tapping system and using method thereof

A technology of fast vacuum and vacuum device, applied in the field of slag discharge system, can solve the problems of long production cycle, easily scratched crystallizer, low production efficiency, etc., and achieve the effect of low cost, small impact and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

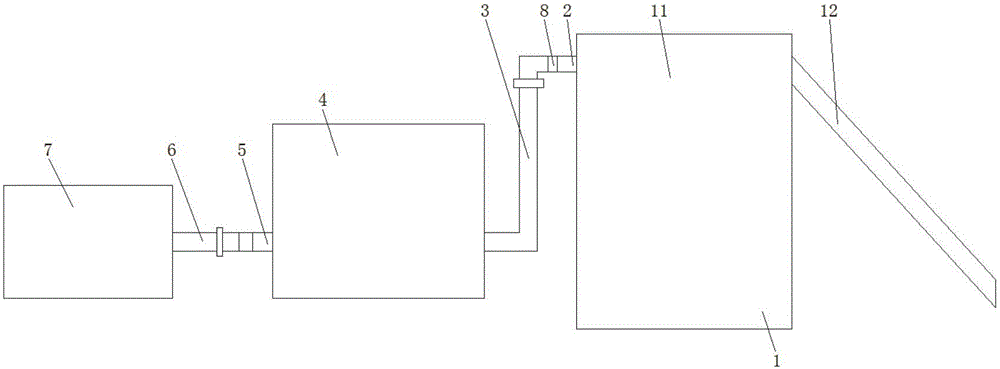

[0020] refer to figure 1 , this embodiment proposes a vacuum rapid slag removal system, including a slag suction tank 1, the slag suction tank 1 includes a slag storage tank 11 and a slag suction pipe 12, the slag suction pipe 12 is located on one side of the slag storage tank 11, and the suction The slag pipe 12 is connected with the air inlet of the slag storage tank 11, and the other side of the slag storage tank 11 is provided with a first air outlet pipe 2, and one end of the first air outlet pipe 2 is connected with the air outlet of the slag storage tank 11, and the first The other end of the air outlet pipe 2 is connected to a metal hose 3 through a connecting device, and the end of the metal hose 3 away from the first air outlet pipe 2 is connected to the air inlet of the intermediate tank 4, which is located on the other side of the slag storage tank 11 , and the gas outlet of the intermediate tank 4 is connected with a second gas outlet pipe 5, the second gas outlet...

example 1

[0024] Example 1: The diameter of the slag suction pipe 12 is 40 mm, the length is 500 mm, the diameter of the slag storage tank 11 is 250 mm, and the height is 320 mm; the angle between the slag suction pipe 12 and the slag storage tank 11 is 45 degrees; When; the diameter of metal hose 3 is 28mm, the diameter of high-pressure hose 6 is 10mm, connect vacuum device 7, intermediate tank 4 and slag suction tank 1, close the air valve 8 in the first air outlet pipe 2, open the second The air valve 8 in the air outlet pipe 5, open the vacuum device 7, and evacuate to -60kpa, the air valve 8 in the second air outlet pipe 5, lift the slag suction pipe 12 with a crane, and insert it into the slag pool that needs slag suction , 25mm away from the metal liquid surface, quickly open the air valve 8 in the first gas outlet pipe 2, all the slag liquid above 25mm away from the metal liquid is sucked into the slag storage tank 11, after the slag suction is completed, the slag suction pipe 12...

example 2

[0025] Example 2: The diameter of the slag suction pipe 12 is 60mm, the length is 420mm, the diameter of the slag storage tank 11 is 380mm, and the height is 480mm; the angle between the slag suction pipe 12 and the slag storage tank 11 is 45 degrees; when the slag suction 20kg The diameter of the metal hose 3 is 30mm, and the diameter of the high-pressure hose 6 is 12mm. Connect the vacuum device 7, the intermediate tank 4 and the slag suction tank 1, close the air valve 8 in the first air outlet pipe 2, and open the second air outlet. The air valve 8 in the air pipe 5, open the vacuum device 7, evacuate to -82kpa, the air valve 8 in the second air outlet pipe 5, use the crane to lift the slag suction pipe 12, insert it into the slag pool that needs slag suction, With a distance of 22mm from the metal liquid surface, quickly open the air valve 8 in the first air outlet pipe 2, and all the slag liquid above 25mm from the metal liquid will be sucked into the slag storage tank 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com