Enthalpy difference method test system containing nozzle sealing mechanism

A technology of a test system and a sealing mechanism, which is applied to the field of the comprehensive test device of the air conditioner enthalpy difference method, can solve the problems affecting the accuracy of the air conditioner enthalpy difference test result, the sealing is not strict, etc., and achieves the effects of simple structure, easy adjustment and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

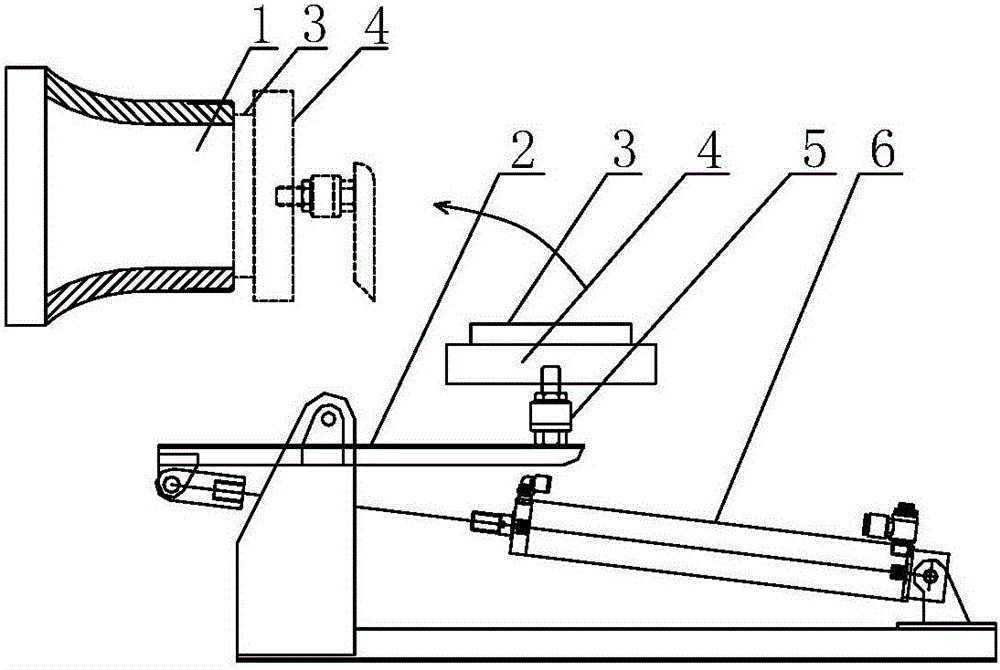

[0040] like figure 2 , 3 As shown, the nozzle sealing mechanism of the present invention includes a plug 4 for blocking the nozzle 1 in the wind tunnel. The diameter of the spherical sealing structure 3 is larger than the diameter of the nozzle 1 , the radial dimension of the top of the cone of the conical sealing structure 3 is smaller than the diameter of the nozzle 1 , and the radial dimension of the bottom of the cone is larger than the diameter of the nozzle 1 . That is, when the present invention is used to block the nozzle 1 in the wind tunnel mechanism, the spherical sealing structure 3 extends into the interior of the nozzle 1, or the cone tip of the conical sealing structure 3 extends into the interior of the nozzle 1. Due to the diameter of the spherical sealing structure 3 Larger than the diameter of the nozzle 1, the radial dimension of the top of the cone of the conical sealing structure 3 is smaller than the diameter of the nozzle 1, and the radial dimension of ...

Embodiment 2

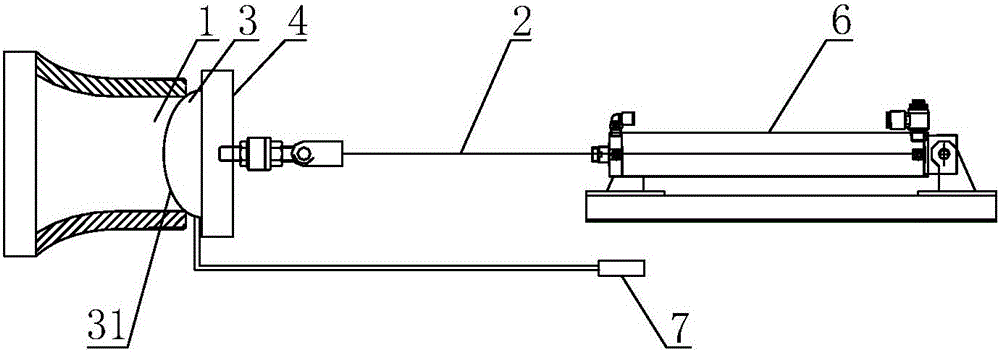

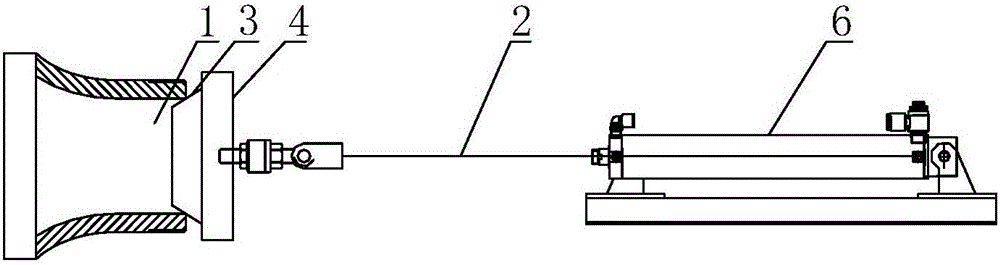

[0045] like Figure 4 As shown, the enthalpy difference method test system including the nozzle sealing mechanism of the present invention includes an indoor simulation room 10a, an outdoor simulation room 10b and a control mechanism; the indoor simulation room 10a is provided with an air conditioner indoor unit 20a, a first temperature and humidity sampling device 30a, and a wind tunnel mechanism 40 for measuring the circulating air volume of the air conditioner internal unit 20a, the nozzle 1 in the wind tunnel mechanism 40 is provided with a corresponding nozzle sealing mechanism; the outdoor simulation room 10b is provided with an air conditioner external unit 20b, Two temperature and humidity sampling devices 30b; the air conditioner inner unit 20a and the air conditioner outer unit 20b constitute the air conditioner mechanism to be detected;

[0046] The enthalpy difference method test system includes an indoor pressure cooling unit 50a for adjusting the temperature in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com