High-efficiency rotor for motor

A high-efficiency, rotor technology, applied in electric components, electrical components, electromechanical devices, etc., can solve problems such as unstable performance and structure, and achieve the effects of high quality and safety stability, stable structure, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

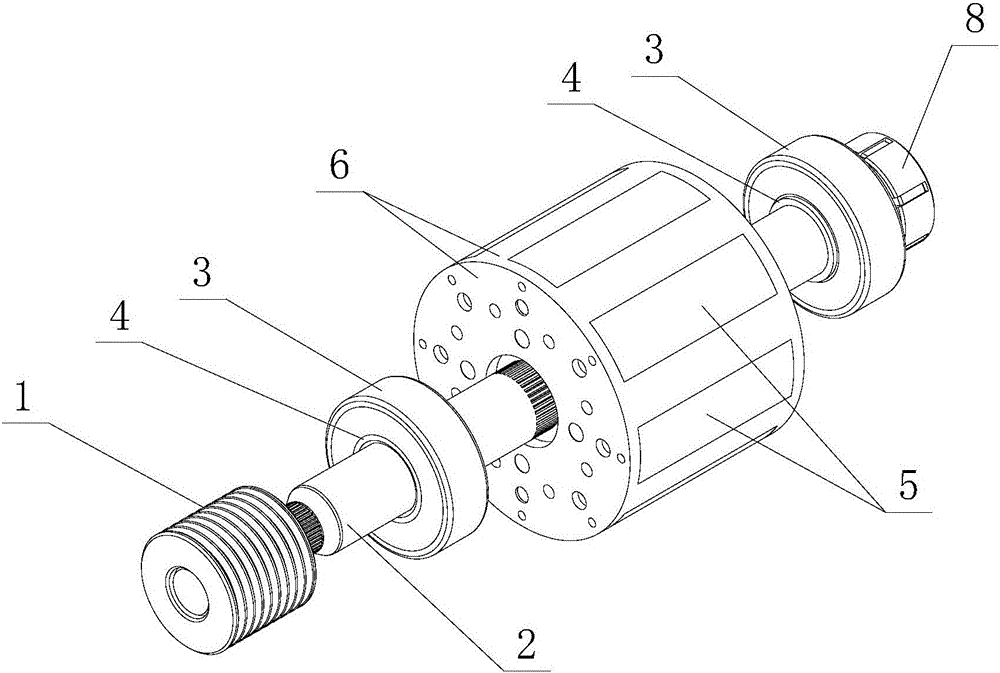

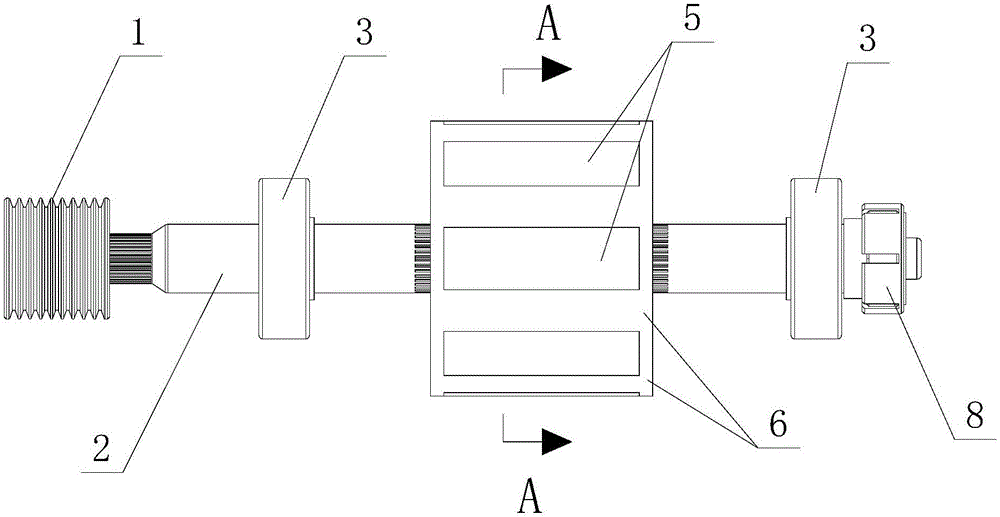

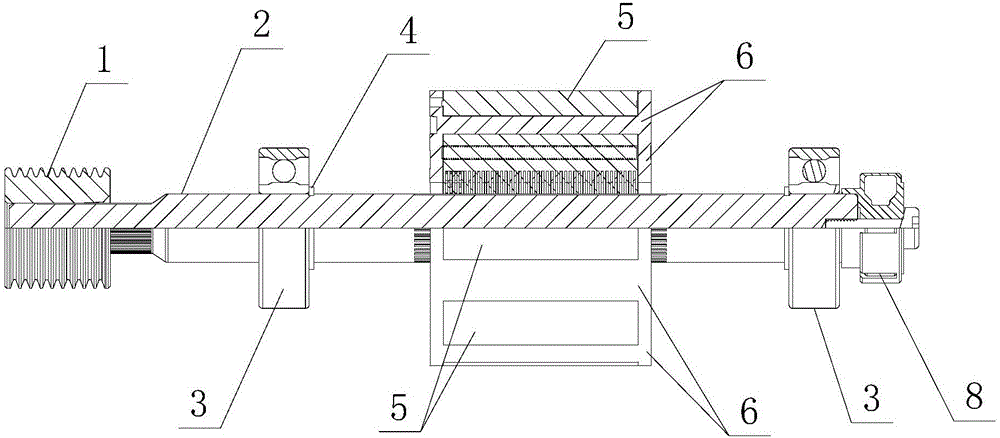

[0012] The present invention will now be described in further detail with reference to the drawings. The drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the structures related to the present invention.

[0013] For specific examples, please refer to figure 1 , figure 2 , image 3 with Figure 4 , A high-efficiency rotor for a motor, comprising a rotating shaft 2, a bearing 3, a bearing fixing circlip 4, and a magnet 7. One end of the rotating shaft 2 is fixed with a pulley 1, and the other end of the rotating shaft 2 is fixed with a magnet ring 8. The bearing 3 is fixed on the rotating shaft 2 by a bearing fixing circlip 4, and the magnet 7 is sealed and fixed in the rotor core 5 by the injection molded plastic 6. The rotor core 5 and the magnet 7 are fixed in the injection molded plastic 6. A bearing 3 is fixed on both sides of the iron core 5 respectively.

[0014] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap