Internal gear honing machine

A technology of honing machine and internal gear, which is applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., which can solve the problems of difficulty in ensuring the grinding efficiency and machining accuracy of internal gears, difficulty, and small internal space of internal gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

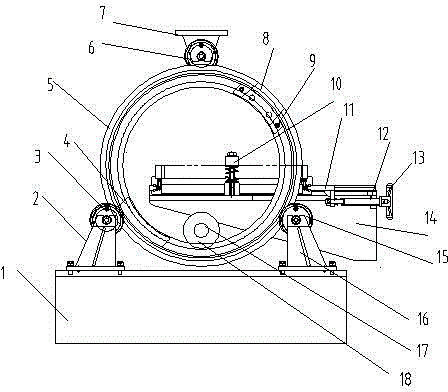

[0012] attached by figure 1 It can be seen that the machine tool consists of a frame 1, a lower left rotating tug wheel frame 2, a lower left tug wheel 3, a lining weight ring 4, a forming grinding wheel 5, an upper rotating supporting wheel 6, an upper supporting wheel frame 7, an embedding ring 8, a connecting plate 9, and a workpiece Pressing plate 10, rotary disc 11, feed screw mechanism 12, hand wheel 13, workpiece support 14, right lower rotating supporting wheel 15, right lower supporting wheel frame 16, driving wheel bracket 17, driving wheel 18 is characterized in that : the frame 1 is a support, the lower left roller frame 2, the upper roller frame 7, the lower right roller frame 15, the workpiece support 14 and the driving wheel support 17 are installed on the frame 1.

[0013] The upper rotating supporting wheel 6 is installed on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com