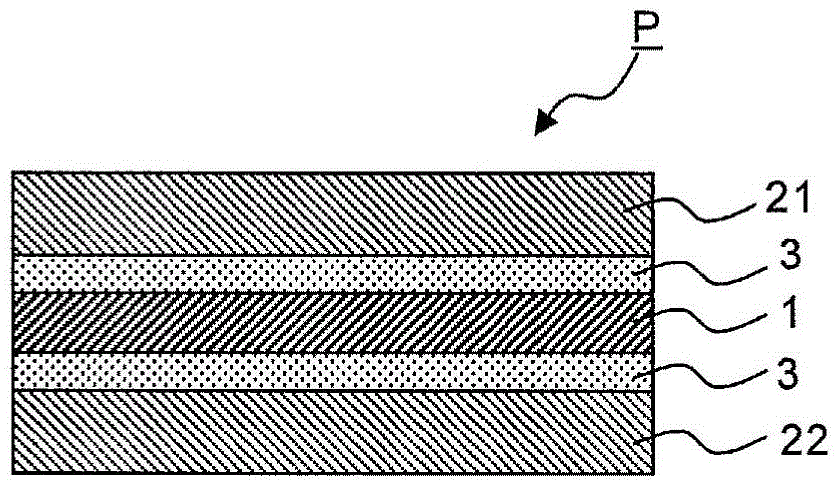

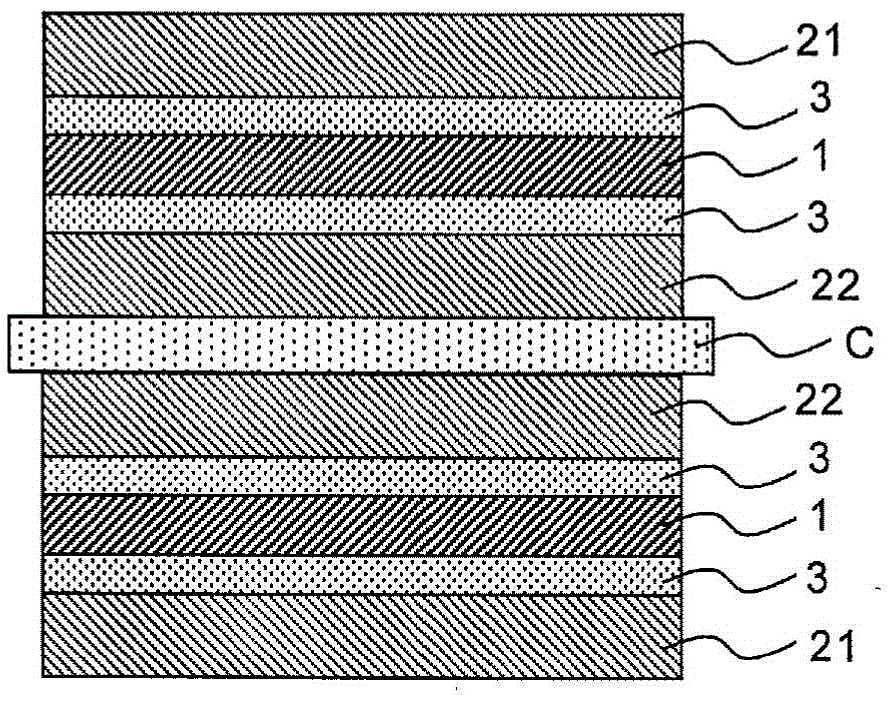

Polarizing plate and liquid crystal display device

A technology of polarizing plates and polarizing plates, which is applied in the field of polarizing plates and liquid crystal display devices, can solve the problem of uneven display of triacetyl cellulose retardation panels, and achieve the effect of good appearance and suppression of scorching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

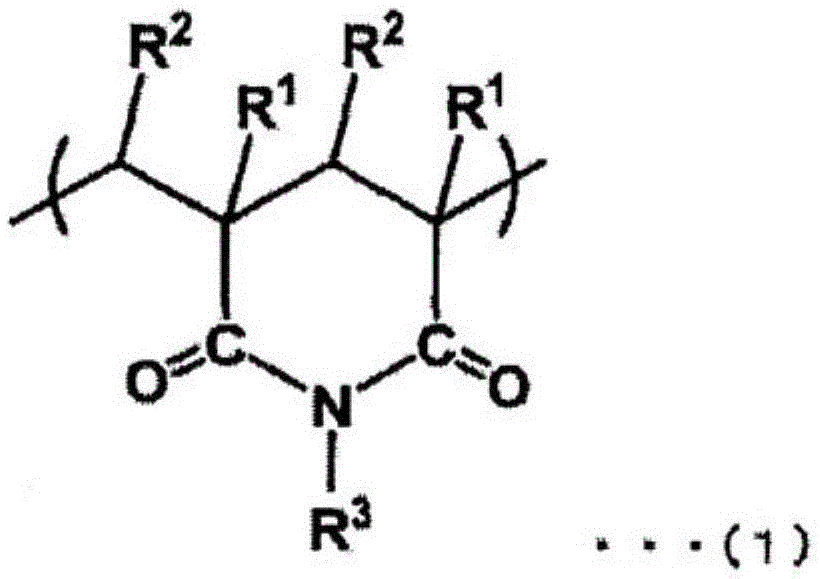

Method used

Image

Examples

Example Embodiment

[0173]

[0174] (production of polarizing plate)

[0175] The above-mentioned adhesive agent A was applied to one side of the above-mentioned transparent protective film A so that the thickness of the adhesive layer after drying became 80 nm, and it was set aside. The above-mentioned adhesive agent A was applied to one side of the above-mentioned transparent protective film G so that the thickness of the adhesive layer after drying became 80 nm, and it was set aside. In addition, the application of the adhesive agent was performed under the temperature condition of 23° C. after 30 minutes from the above-mentioned preparation. Next, the above-mentioned transparent protective films A and G with adhesive were bonded to both surfaces of the polarizing plate with a roll machine at a temperature of 23° C., and then dried at 55° C. for 6 minutes to produce a polarizing plate.

Example

[0176]

[0177] In preparation of the polarizing plate of Example 1, except having changed the kind of transparent protective film and the kind of adhesive agent as shown in Table 1, it carried out similarly to Example 1, and produced the polarizing plate.

[0178] In addition, the coating layer on the surface of the polarizing plate of Examples 4, 5 and Comparative Example 2 was formed by the following procedure. Prepare 50 parts by weight of ultraviolet-curable urethane acrylate resin (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., trade name "UV1700B", solid content 100%), and a multifunctional acrylate mainly composed of pentaerythritol triacrylate (Osaka organic Kagaku Kogyo Co., Ltd. product, brand name "VISCOAT #300", solid content 100%) 50 parts by weight. With respect to 100 parts by weight of the resin solid content of the above resin, copolymerized particles of acrylic acid and styrene (manufactured by Sekisui Chemical Industry Co., Ltd., trade name...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap