A kind of crystallization purification process of pyraclostrobin condensation intermediate

A technology of pyraclostrobin and intermediates, which is applied in the crystallization and purification process field of pyraclostrobin condensation intermediates, can solve the problems of unfavorable purification and refining of final products, great influence on the purity of final products of condensation intermediates, etc., and achieve Good crystallization effect, high crystallization yield and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

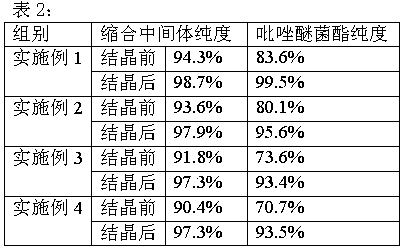

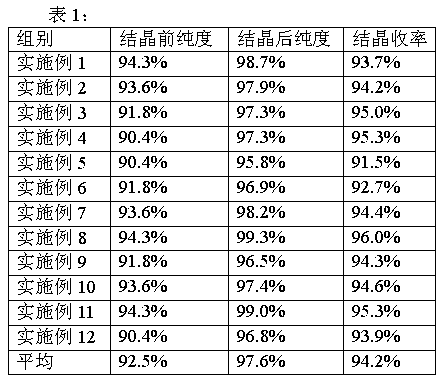

Embodiment 1

[0013] A kind of crystallization purification process of pyraclostrobin condensation intermediate:

[0014] In parts by weight, 80 parts of pyraclostrobin condensation intermediates with a purity of 94.3% were added to the crystallization tank, and then 400 parts of anhydrous methanol and 20 parts of N,N-dimethylformamide were pumped in, Start stirring, heat up to 60-80°C, reflux for 30-60min, cool down to 35-45°C, then slowly add 3 parts of triethylamine dropwise to the crystallization kettle, after the dropwise addition, keep the temperature at 35-45°C, Continue to stir for 15-30min, lower the temperature slowly, control the cooling rate at 5-10°C / h, lower the temperature to 3-8°C, keep stirring for 1-2 hours, filter with suction, collect the mother liquor into the mother liquor tank, and use 3- Rinse twice with a small amount of anhydrous methanol at 8°C, take out the filter cake, and dry it in an oven to obtain high-purity pyraclostrobin condensation intermediate crystals....

Embodiment 2

[0017] A kind of crystallization purification process of pyraclostrobin condensation intermediate:

[0018] In parts by weight, 80 parts of pyraclostrobin condensation intermediates with a purity of 93.6% were added to the crystallization tank, and then 600 parts of anhydrous methanol and 20 parts of N,N-dimethylformamide were pumped in, Start stirring, heat up to 60-80°C, reflux for 30-60min, cool down to 35-45°C, then slowly add 3 parts of triethylamine dropwise to the crystallization kettle, after the dropwise addition, keep the temperature at 35-45°C, Continue to stir for 15-30min, lower the temperature slowly, control the cooling rate at 5-10°C / h, lower the temperature to 3-8°C, keep stirring for 1-2 hours, filter with suction, collect the mother liquor into the mother liquor tank, and use 3- Rinse twice with a small amount of anhydrous methanol at 8°C, take out the filter cake, and dry it in an oven to obtain high-purity pyraclostrobin condensation intermediate crystals....

Embodiment 3

[0021] A kind of crystallization purification process of pyraclostrobin condensation intermediate:

[0022] In parts by weight, 80 parts of pyraclostrobin condensation intermediates with a purity of 91.8% were added to the crystallization tank, and then 800 parts of anhydrous methanol and 25 parts of N, N-dimethylformamide were pumped in. Start stirring, heat up to 60-80°C, reflux for 30-60min, cool down to 35-45°C, then slowly add 5 parts of triethylamine dropwise to the crystallization kettle, after the dropwise addition, keep the temperature at 35-45°C, Continue to stir for 15-30min, lower the temperature slowly, control the cooling rate at 5-10°C / h, lower the temperature to 3-8°C, keep stirring for 1-2 hours, filter with suction, collect the mother liquor into the mother liquor tank, and use 3- Rinse twice with a small amount of anhydrous methanol at 8°C, take out the filter cake, and dry it in an oven to obtain high-purity pyraclostrobin condensation intermediate crystals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com