Measurement gauge used for detecting coaxiality of two internal threads with different rotation directions and detection method thereof

A technology of coaxiality and internal thread, applied in the direction of measuring gauge, plug gauge, etc., can solve the problem of lack of mature technical means, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

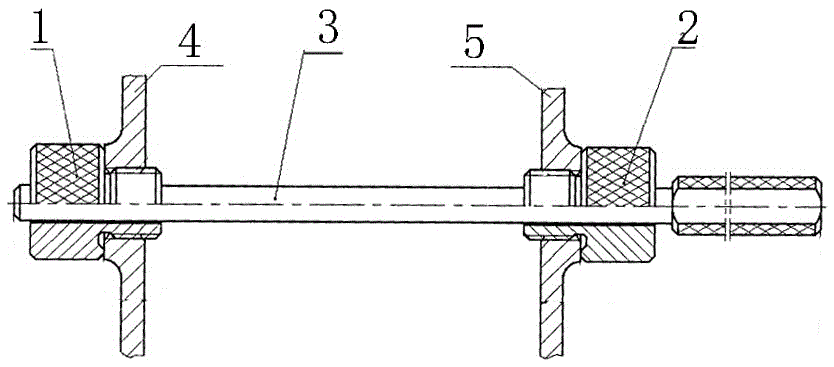

[0009] This patent is only applicable to the measurement of the coaxiality of two internally threaded holes with different directions of rotation, and conventional thread plug gauges are used for accurate thread measurement. This article takes the coaxiality measurement of the parts with M12×1.5LH-5H6H and M12×1.5-5H6H two threaded holes requiring a coaxiality of 0.1 as an example to illustrate.

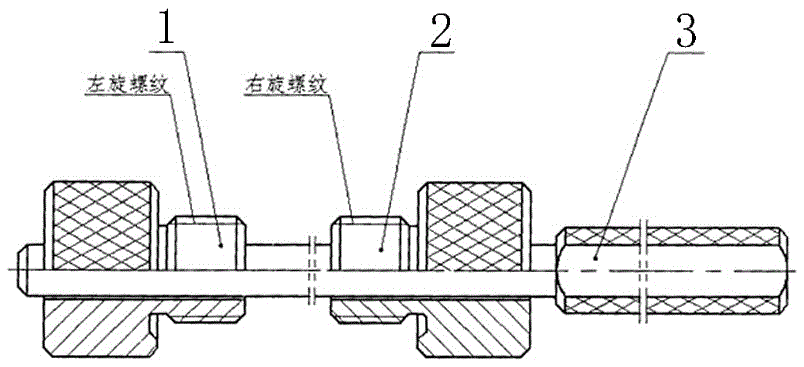

[0010] A gauge used to detect the coaxiality of two internal threads with different directions of rotation, the structure is as follows figure 1 As shown, it includes thread gauge Ⅰ1, thread gauge Ⅱ2 and pin 3, wherein the left-handed thread of thread gauge Ⅰ1 matches the left-handed thread of the part to be tested Ⅰ4, and the right-handed thread of thread gauge Ⅱ2 matches with the part to be tested Ⅱ5. The right-handed thread cooperates and plays a positioning role together. The φ6 axis on the pin 3 is matched with the φ6 holes on the thread gauge I1 and the thread gauge II2 as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com