An Auxiliary Tooling for Improving the Testing Accuracy of Fracture Toughness of Aluminum Alloy Sheet

A technology of fracture toughness and auxiliary tooling, which is applied in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc. Simple and reasonable, easy to operate, and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

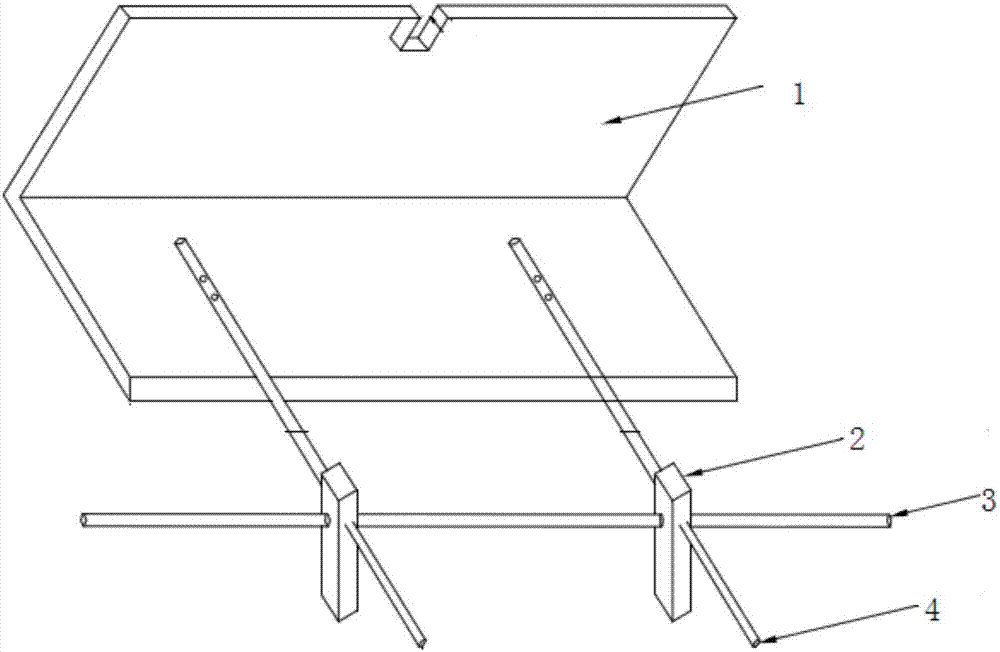

[0021] Such as figure 1 As shown, an auxiliary tooling for improving the testing accuracy of the fracture toughness of aluminum alloy sheets includes an anti-warping Z-shaped plate 1 and a fixing frame composed of at least three column parts perpendicular to each other; One side of a horizontal plate of the Z-shaped plate, constituting a longitudinal part of a column type mobile handle 4 of the fixed mount 2 is fixed on the horizontal plate. There is a rectangular groove in the center of one side of the edge, which is used to align the center hole of the aluminum alloy sheet for testing. The number of the column-shaped elements perpendicular to the horizontal direction of the horizontal plane of the horizontal plate is at least two. The other side is symmetrically provided with the moving handle 4 along the direction perpendicular to the central axis of the anti-warping Z-shaped plate 1, the other end of the moving handle 4 passes through the fixed bracket 2, and the sliding ...

specific Embodiment 2

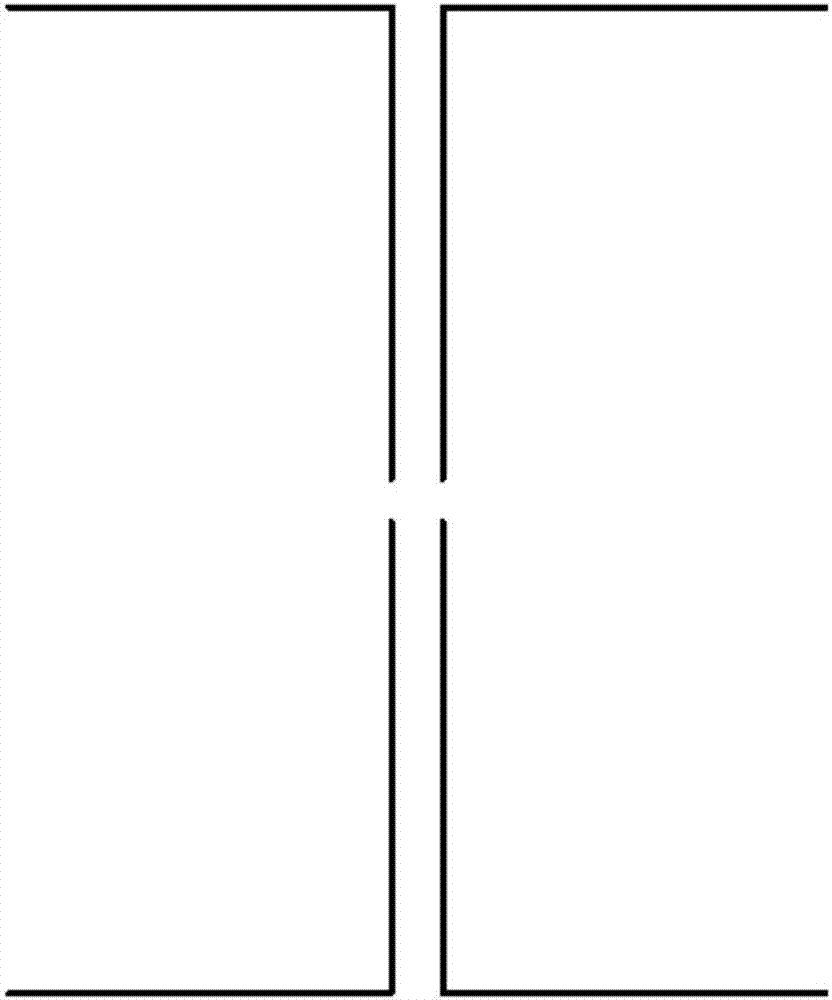

[0022] Such as figure 2 Shown is a simulation diagram of the combination of anti-warping Z-shaped plates, and the four anti-warping Z-shaped plates are installed and combined in a rectangular shape. First, apply lubricating oil on the surface of the anti-warping Z-shaped plate of the auxiliary tool that contacts the aluminum alloy sheet style. Teflon plastic film or heavy oil, or both, can be used to reduce the distance between the test aluminum alloy sheet style and the auxiliary tool. friction.

[0023] Install the 8 fixed brackets 2 of the auxiliary tool horizontally on the 4 columns of the fatigue testing machine, make the faces of the 4 anti-warping Z-shaped plates 1 smeared with lubricating oil face each other, and place the sample on the Meanwhile, ensure that the pattern of the aluminum alloy sheet is straight, and adjust the anti-warping Z-shaped plate 1 to move forward and backward by rotating the moving handle 4 to keep it in close contact with the pattern of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com