A lower-adjustable high-precision fast hydraulic press, its mold adjustment cylinder, and its mold adjustment method

A high-precision, press technology, applied in the field of hydraulic presses, can solve the problems of large mold adjustment errors, complex structures, and high maintenance costs, and achieve the effects of fast mold adjustment, reduced processing difficulty, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

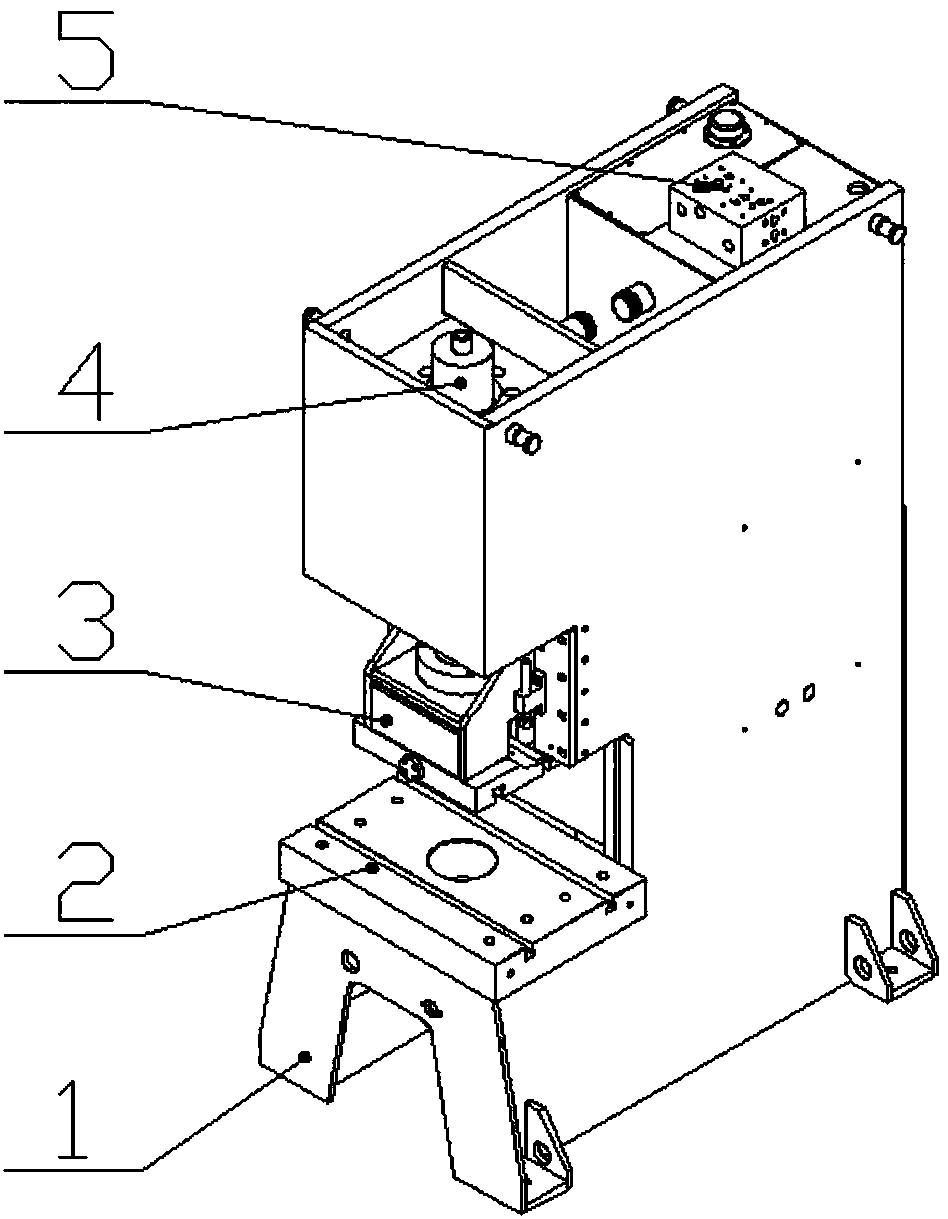

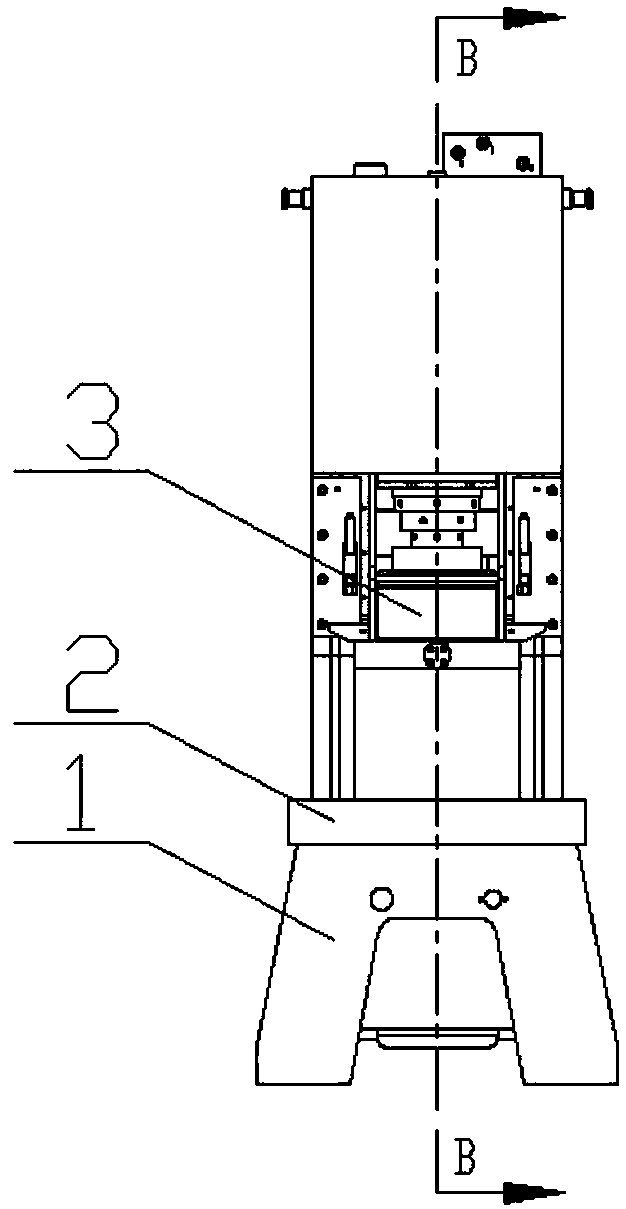

[0047] Such as figure 1 , figure 2 and image 3As shown, a lower-adjustment high-precision rapid hydraulic press includes a body 1, a workbench 2, a slider 3, and a hydraulic system. The hydraulic system includes a hydraulic valve group 5, an oil tank 6, an oil pump assembly 7, and a mold adjustment cylinder 4. Workbench 2, mold adjustment cylinder 4, hydraulic valve group 5, fuel tank 6 and oil pump assembly 7 are all fixed on the fuselage 1, and slider 3 is fixed on the lower end of mold adjustment cylinder 4;

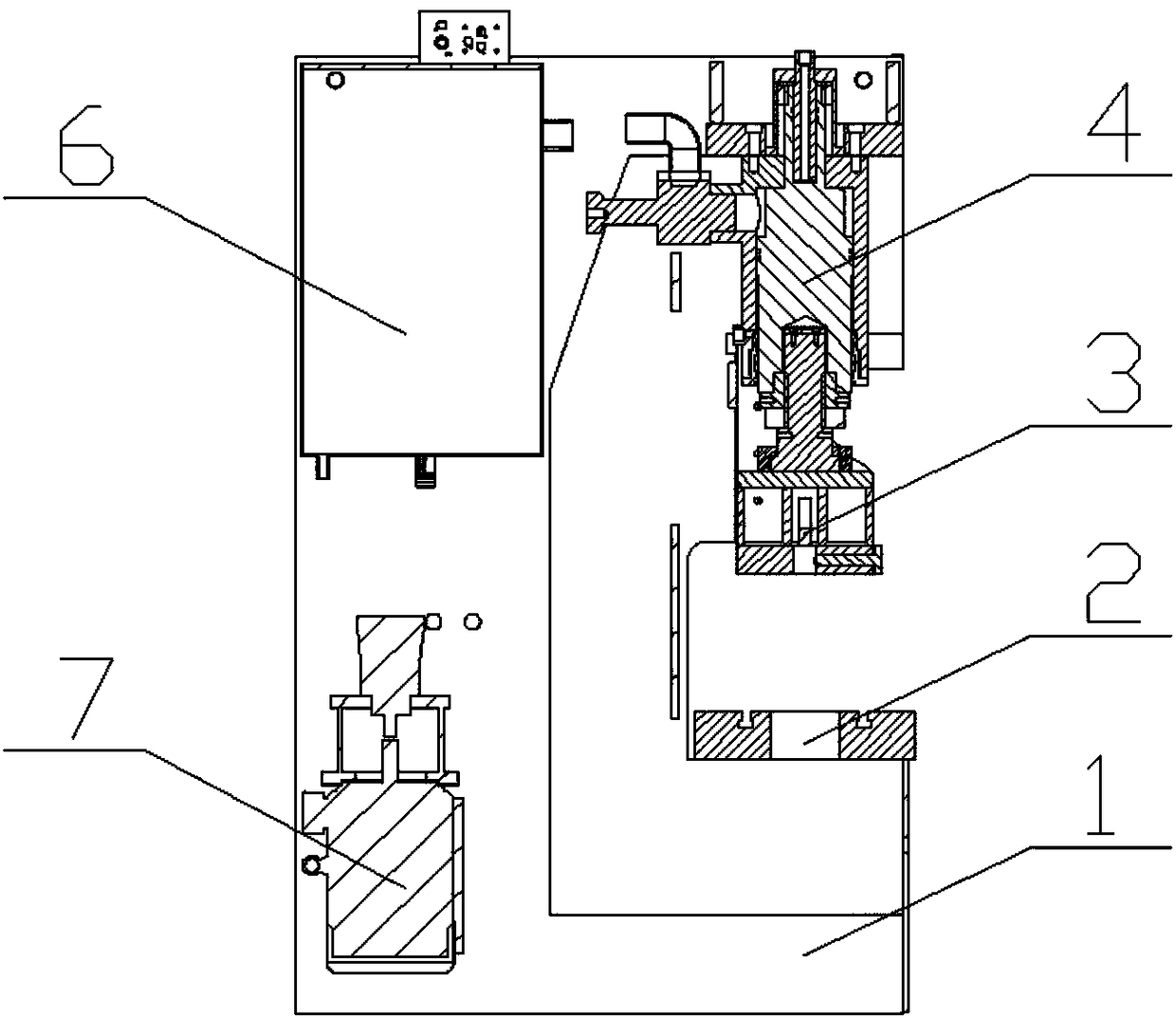

[0048] Such as Figure 4 , Figure 5 and Figure 6 As shown, the mold adjusting oil cylinder 4 includes a main cylinder, an auxiliary cylinder and an adjusting screw rod 41. The master cylinder includes a master cylinder body 44 and a master cylinder piston rod 43 arranged in the master cylinder body 44. The upper end of the master cylinder piston rod 43 extends out Outside the main cylinder body 44; the auxiliary cylinder includes a fast cylinder piston rod 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com