Profile auto-laminating device

A film sticking device and profile technology, applied in the field of automatic profile sticking device, can solve the problems of affecting the appearance quality of profile products, poor consistency, affecting sales, etc., and achieve the effects of good product consistency, simple work control, and small fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments.

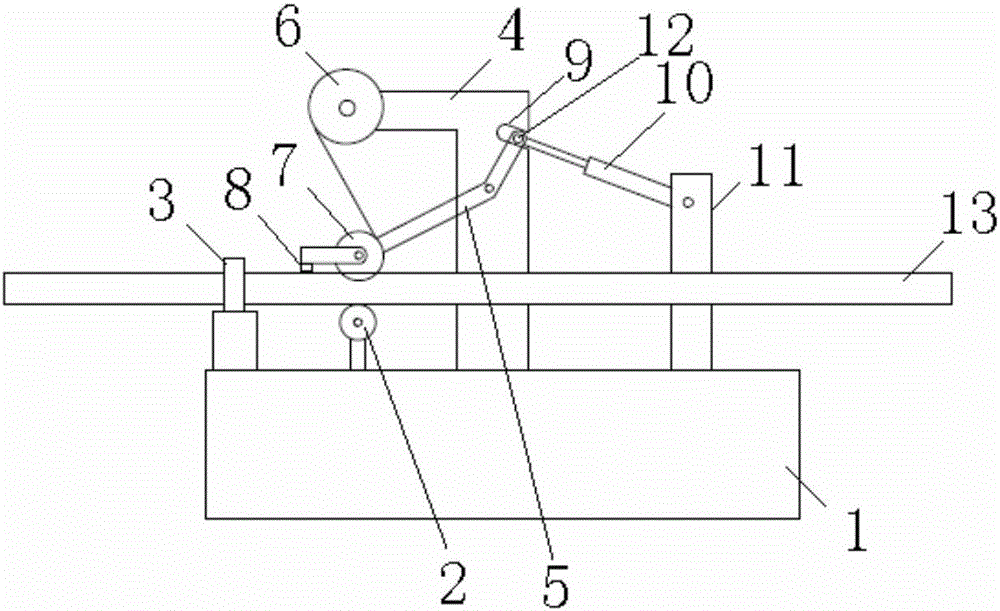

[0019] Such as figure 1 with figure 2 As shown, the automatic film sticking device for profiles includes a base 1, a support frame 4, and a pressure roller 7, wherein the lower end of the support frame 4 is fixed on the base 1, and the upper part of the support frame 4 is provided with a film reel for installing the film roll, the film roll 6 The cover is rotatable on the film reel.

[0020] The support frame 4 is hinged with a connecting rod 5, the bending part of the connecting rod 5 is arranged on the support frame 4 through a shaft, the pressure roller 7 is hinged on one end of the connecting rod 5, and the base 1 is provided with a cylinder 10 through a fixing frame 11, the piston of the cylinder 10 The rod and the other end of the connecting rod 5 are hinged through the shaft 12, and the up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap