Heater with hollow annular cylinder heat exchanger

A heat exchanger, hollow technology, applied to vessels with enlarged heating surfaces, heating methods, gaseous heating fuels, etc., can solve the problems of large heat loss and low thermal efficiency, and achieve high utilization efficiency, fast heat transfer rate, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

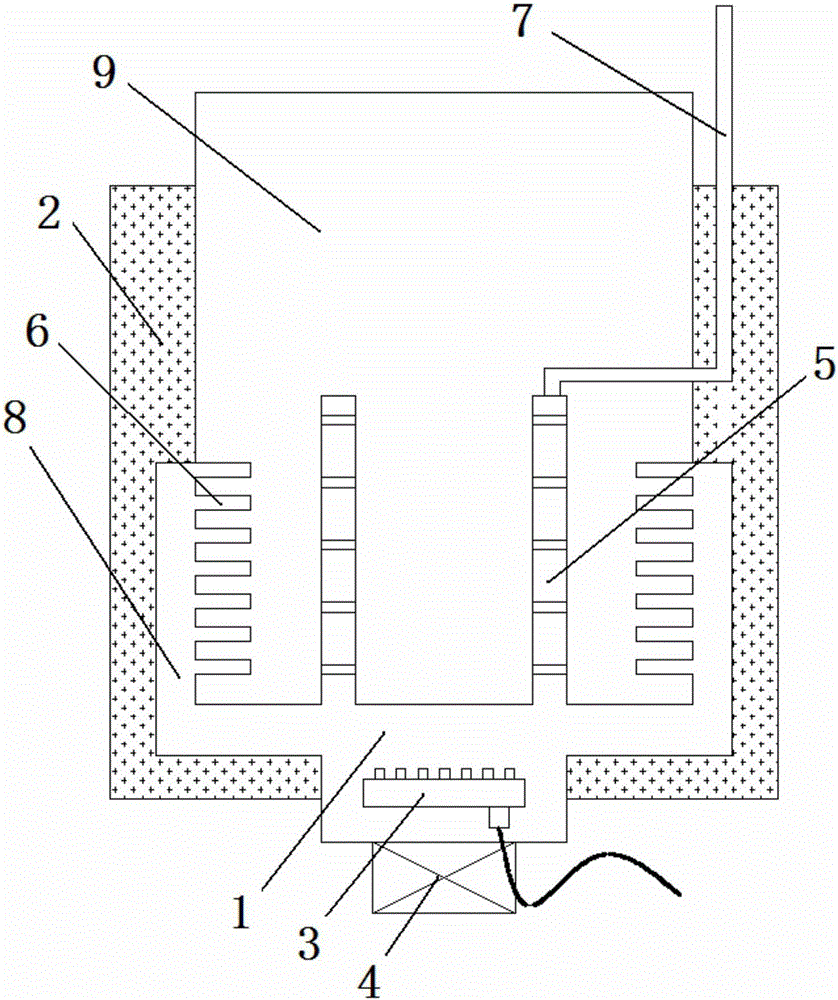

[0016] A heater provided with a hollow annular cylindrical heat exchanger, characterized in that it includes a pot body 9, a thermal insulation material layer 2, a hollow fin ring 6, a thermal insulation chamber 8, a combustion chamber 1, a fan 4, and a gas combustion disk 3 , a hollow annular cylinder heat exchanger 5 and a smoke pipe 7,

[0017] The combustion chamber 1 is located at the bottom of the pot body 9, the heat preservation chamber 8 surrounds the outer wall of the pot body 9, the heat preservation chamber 8 communicates with the combustion chamber 1, the heat insulating material layer 2 is wrapped around the heat preservation chamber 8 and the outside of the combustion chamber 1, and the fan 4 is installed in the combustion chamber At the opening of the lower end of 1, the gas burning disc 3 is located in the combustion chamber 1,

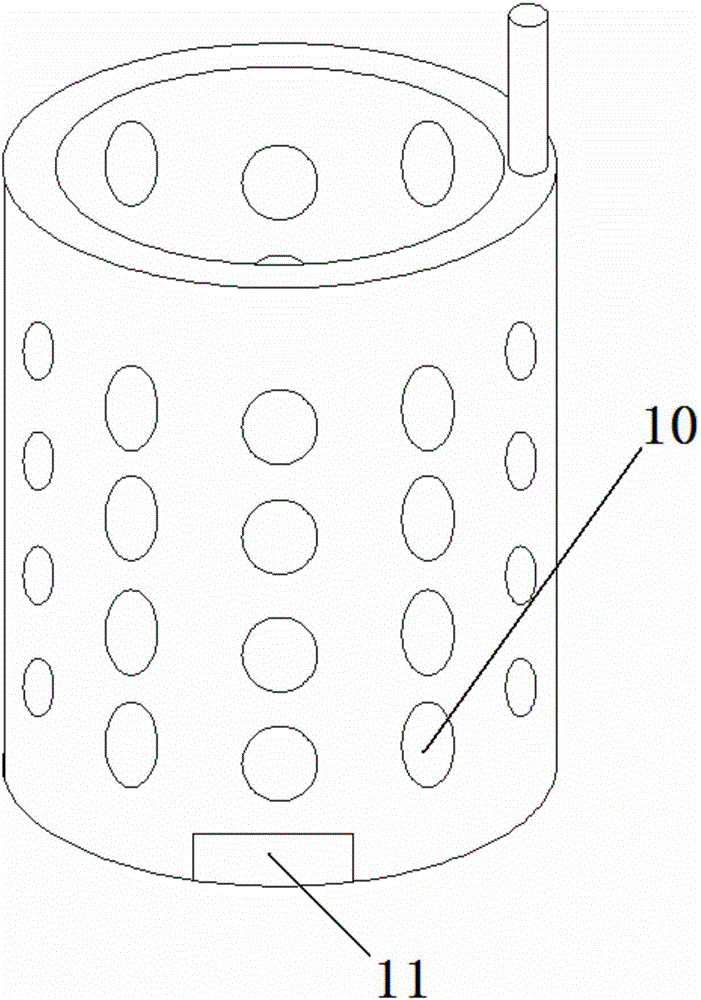

[0018] The hollow annular cylinder heat exchanger 5 is installed in the pot body 9, and the side of the hollow annular cylinder heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com