Adjustable bracket for crankshaft detection

An adjustable, crankshaft technology, used in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of troublesome, time-consuming, difficult operation, etc., and achieve the effect of easy and convenient rotation, convenient use, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

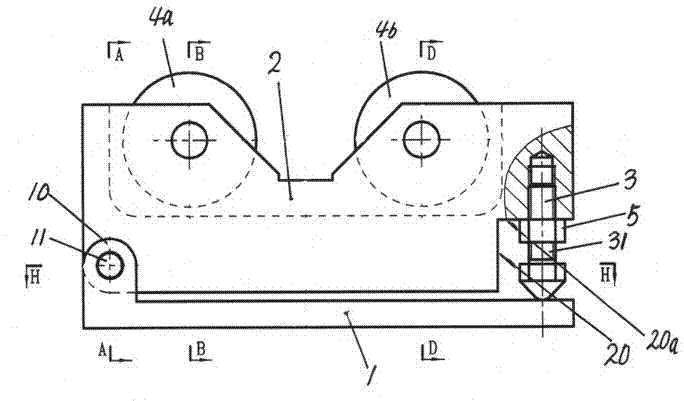

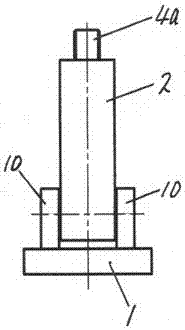

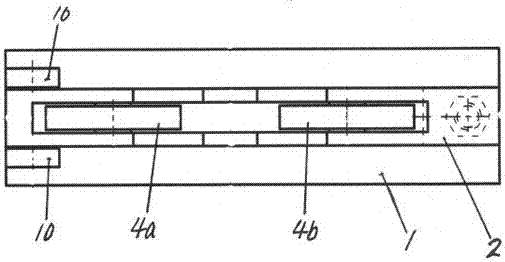

[0014] The crankshaft detection adjustable support of the present invention is made of base 1, V-shaped iron 2, left and right rotating support rollers 4a, 4b, height adjustment screw ejector rod 3 and lock nut 5 thereof; The opened hinge shaft seat 10 is hingedly connected by the hinge shaft 11, and the lower end of the other side of the V-shaped iron 2 is provided with a notch table 20, and a screw ejector rod 3 and a lock nut thereof are arranged on the table surface 20a of the notch table 20. 5. The bottom end of the screw ejector rod 3 acts on the upper surface of the base 1 to make the V-shaped iron 2 rotate and lift around the hinge shaft 11 to adjust the height of the V-shaped iron 2. It is arranged symmetrically on the left and right sides of the V-shaped groove of the V-shaped iron 2 The left and right rotating support rollers 4a, 4b are installed respectively, and the left and right rotating support rollers 4a, 4b replace the V-shaped groove surface of the V-shaped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com