Backpressure steam turbine drive system with low pressure deaerator mixed heat exchange condensing

A hybrid heat exchange and drive system technology, which is applied in the field of steam turbines, can solve the problems of power plant power consumption rate decline and achieve the effects of improving thermal efficiency, reducing enthalpy drop loss, and reducing cold end loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

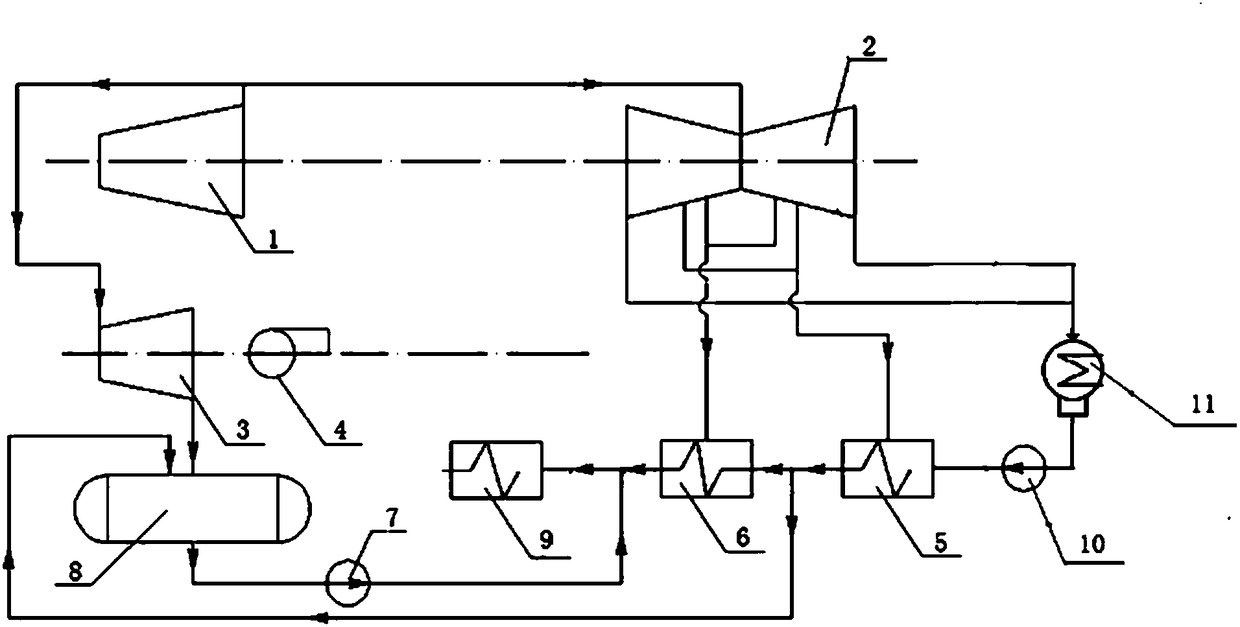

[0026] like figure 1 As shown, the present invention is aimed at the south and some areas without heat supply, in order to realize the driving of the main steam turbine and avoid the pure condensation method with low efficiency and high cost. The back pressure steam turbine drive system with low pressure deaerator mixed heat exchange condensation in the preferred embodiment of the present invention mainly includes a main steam turbine, the high and medium pressure cylinder 1 of the main steam turbine is used to provide driving steam, and the low pressure cylinder 2 of the main steam turbine is used to provide condensed water; Drive the steam turbine 3, the steam intake of the driving steam turbine 3 is provided by the exhaust steam of the high and medium pressure cylinder 1, preferably the exhaust steam of the medium pressure cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com