Catalyst compositions for ethylene dimerization

A composition and catalyst technology, applied in the direction of catalysts, hydrocarbons, hydrocarbons, etc., can solve the problems of excessively long initial induction period of polymer formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

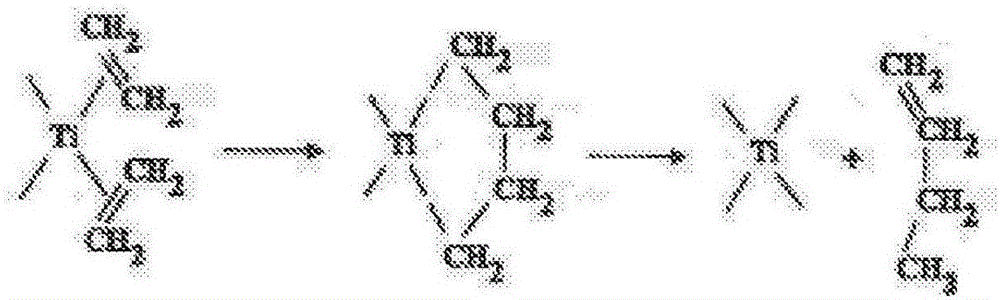

Method used

Image

Examples

Embodiment 1

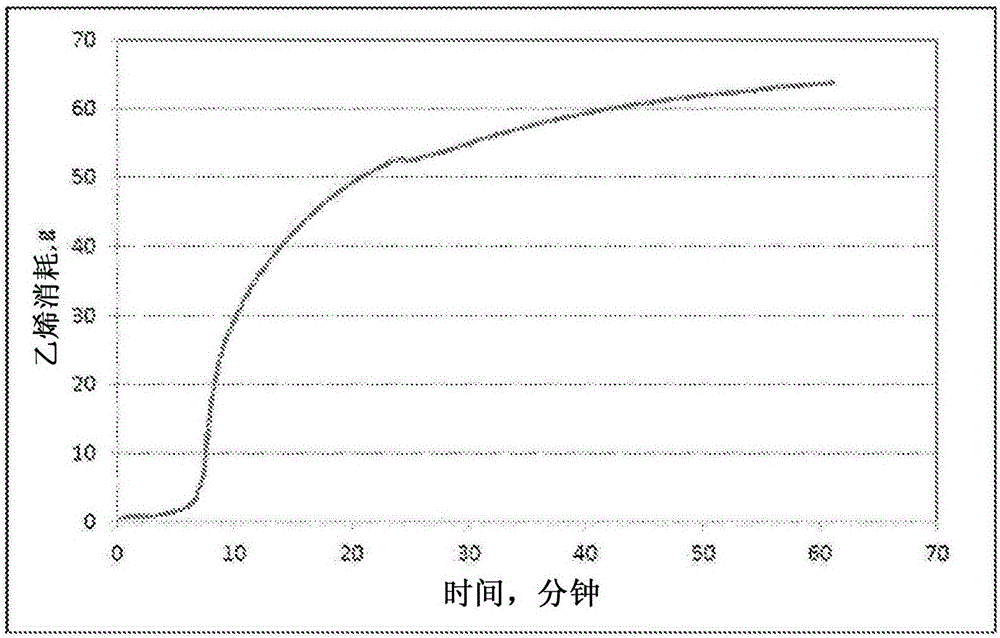

[0039] 2.75 ml of TNBT were mixed with 2.65 ml of 1,4-dioxane (with a density p of 1.03). About 2.2 ml of 1M TEAL dissolved in 50 ml of n-hexane was added to 50 ml of TNBT / 1,4-dioxane mixture to obtain a catalytic solution. The catalytic solution was added to the reactor by vacuum suction. The reactor was then pressurized with ethylene from a 2 liter aluminum cylinder (ethylene supply) to the desired pressure (23 bar in most experiments). The reaction pressure was controlled using a back pressure regulator while the ethylene consumption was measured using a scale on which the gas cylinder was placed. The reactor was equipped with thermocouples to measure the temperature inside the reactor. Record temperature, pressure, and ethylene consumption data using a data acquisition system. Before the catalyst solution was injected, the reactor was heated to 80° C. under vacuum for at least two hours to remove all traces of moisture. Temperature controlled by heating mantle / furnace ...

Embodiment 2

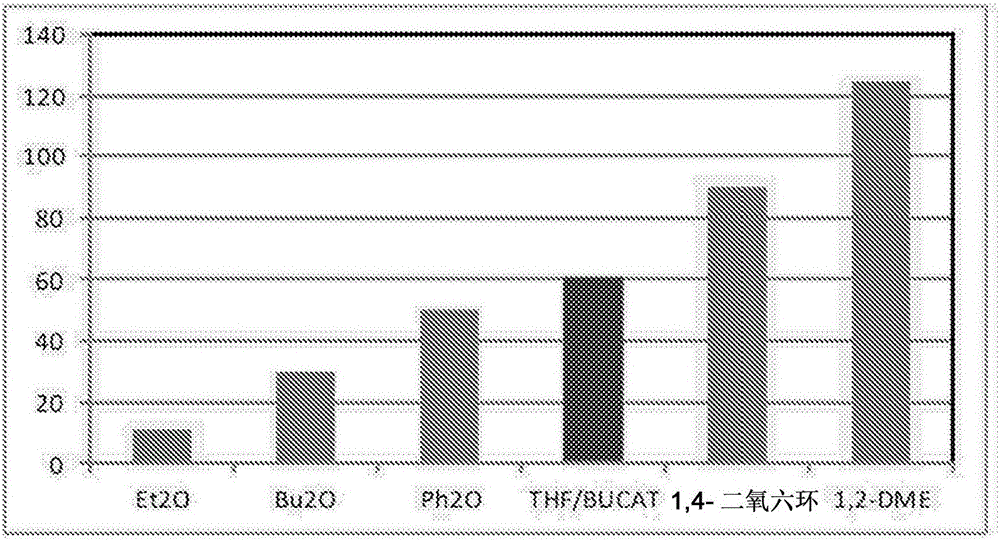

[0053] A mixture of TNBT, 1,4-dioxane and THF was prepared. These mixtures were then mixed with about 2.3 ml of a 1M TEAL solution dissolved in 50 ml of n-hexane to obtain a catalytic solution for the preparation of 1-butene as described in Example 1 above. The total ethylene consumption of these mixtures after 1 hour is shown in Table 1.

[0054] Table 1

[0055]

[0056] The present invention is further illustrated by the following embodiments.

Embodiment approach 1

[0057] Embodiment 1. A catalyst composition comprising an organotitanium compound, an organoaluminum compound, and a cyclic diether, a linear diether, or a combination comprising at least one of the foregoing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com