A kind of preparation and application method of phosphorus removal agent

A technology of chemicals and influent total phosphorus, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Water quality compliance and other issues, to achieve the effect of improving sludge settling performance, efficient phosphorus removal, and extreme sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

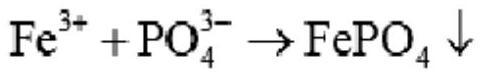

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation and use of embodiment 1 phosphorus removal agent

[0022] With a processing scale of 80000m 3 / d, use the sewage treatment plant of CASS technology as the implementation object, and carry out productive experiments. The CASS process flow is as follows: the sewage enters the aeration grit chamber after being pretreated by the thick and fine grids, and the effluent from the grit chamber enters the biochemical reaction pool. The CASS tank is the experimental group), using a six-cycle operation process, in which water intake is 1 hour, reaction is 1 hour (aeration starts after 0.5 hours of water intake, and the actual aeration reaction takes 1.5 hours), precipitation is 1 hour, and decanting water (D) = 1 hour . The sediment effluent from the CASS biochemical pool is finally discharged after ultraviolet disinfection.

[0023] The test began on June 15 and ended on July 8. Iron powder with a micron mesh of 400 mesh and aluminum powder with a micron mesh of 400...

Embodiment 2

[0027] The effect of embodiment 2 dephosphorization agent

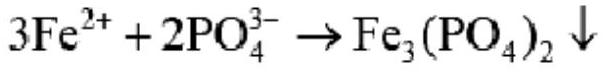

[0028] Every two days, get raw water and embodiment 1, comparative example 1, comparative example 2, the total phosphorus content of the effluent after comparative example 3 treatment compares, and total phosphorus content ammonium molybdate spectrophotometry is measured, and concrete data is shown in Table 1; The total nitrogen content of the effluent in Example 1 is compared with the total nitrogen content of the effluent of the comparative example 3 system, and the specific data are shown in Table 2; table 3.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

[0033] table 3

[0034]

[0035]

[0036]As can be seen from Table 1, for sewage with low influent total phosphorus concentration, the phosphorus removal effect of Example 1 is obviously better or stable than that of Comparative Examples 1-3, and Comparative Example 3 only relies on biological phosphorus removal, and the phosphorus removal ef...

Embodiment 3

[0037] The long-term use effect of embodiment 3 dephosphorization agent

[0038] Similarly, the sewage treatment plant in Example 1 is used as the treatment object to carry out production and application. From June 2015 to April 2016, add 20 tons of this patent dephosphorization agent (micron order number is 400 mesh iron powder) in total, The total treated water volume is 4.0058 million tons, and the average dosage concentration is about 5mg / L. When the influent total phosphorus concentration is about 2mg / L, the effluent average total phosphorus concentration has been between 0.3-0.5mg / L for a long time, achieving stability Up to the standard, the drug cost is about 0.03 yuan / m 3 , which is only 1 / 2 of the cost of conventional metal salt agents. Since this product has a long-lasting phosphorus removal effect, long-term use of the product of the present invention can effectively reduce the cost of agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com