Device for preventing ice blockage during supercooling process ice slurry production by utilizing residual heat and control method thereof

A supercooling and ice slurry technology, applied in subcoolers, refrigerators, damage protection and other directions, can solve the problems of system energy loss, ice formation, limited effect, etc., and achieve high economic benefits, stable performance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

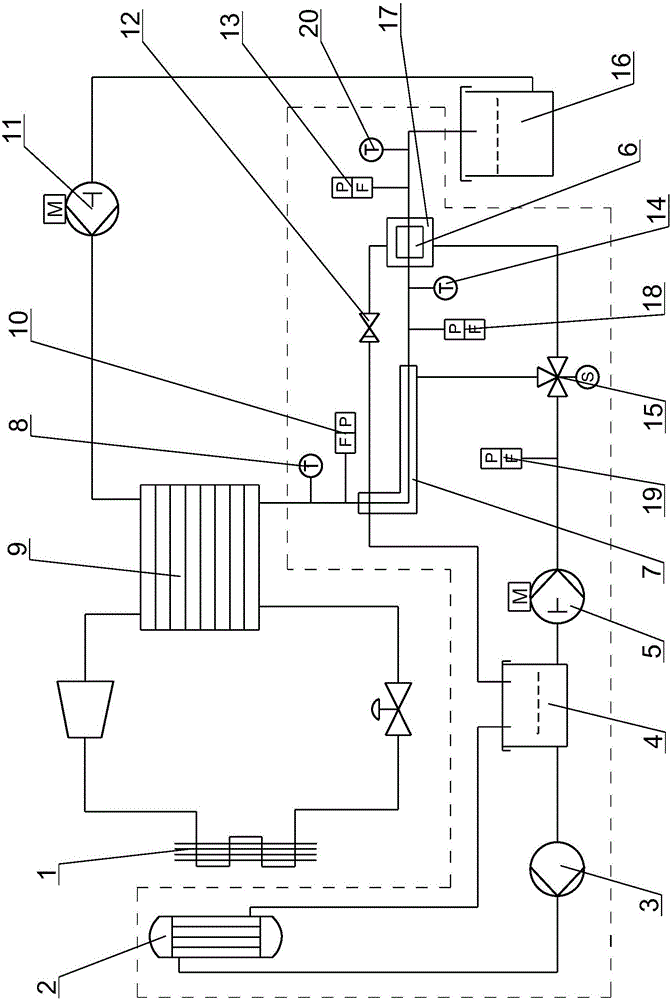

[0018] see figure 1 A device for producing ice slurry and ice blockage by using waste heat to prevent supercooling method, including condenser 1, heat exchanger 2, quantitative pump 3, heat storage water tank 4, anti-blocking variable pump 5, supercooling remover 6, casing type Heat exchanger 7, first temperature sensor 8, subcooler 9, first pressure flow sensor 10, subcooling variable pump 11, check valve 12, second pressure flow sensor 13, second temperature sensor 14, two two three Through the solenoid valve 15 , the cold storage water storage tank 16 , the subcooling heat exchanger 17 , the third pressure flow sensor 18 , the fourth pressure flow sensor 19 and the third temperature sensor 20 .

[0019] In this embodiment, the cold storage w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com